SLS (Selective Laser Sintering) Service

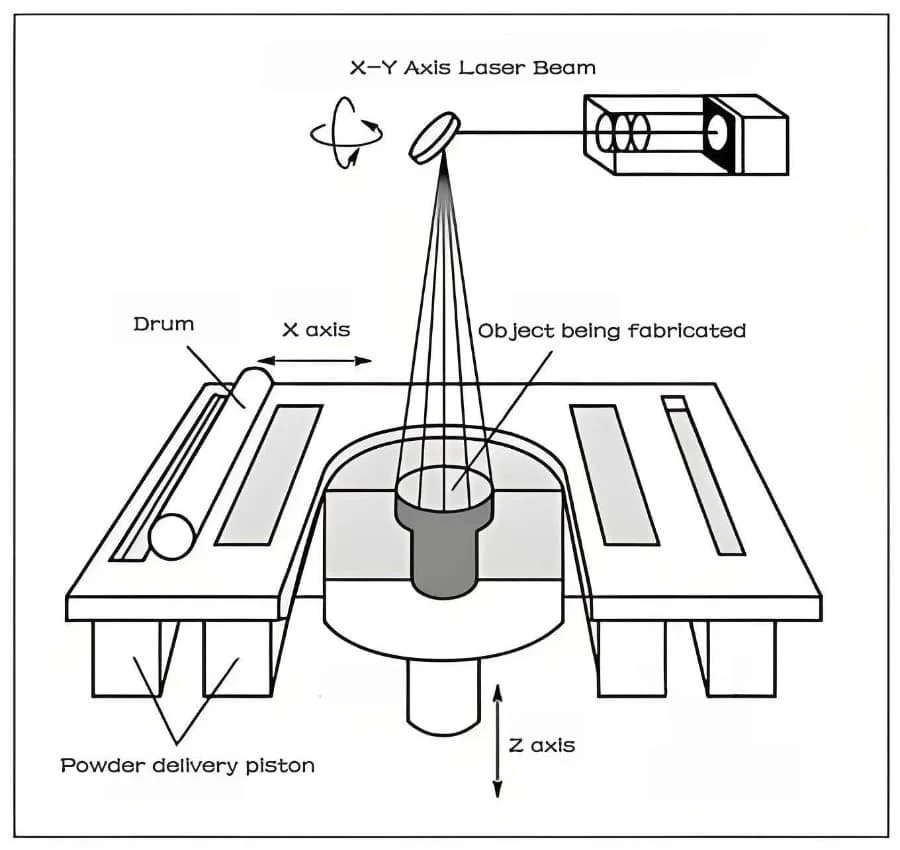

How does Selective Laser Sintering (SLS) work?

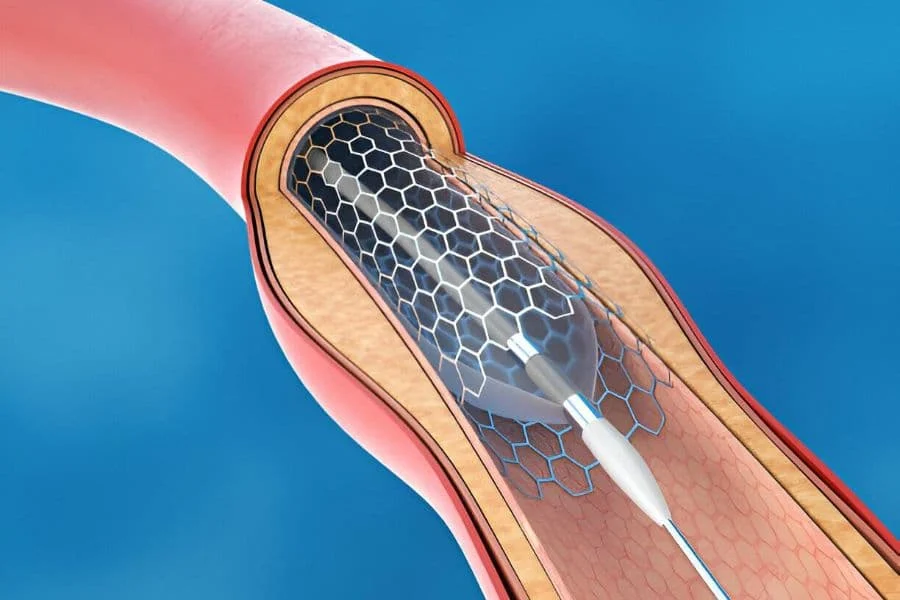

SLS uses lasers for melting nylon powder into plastic. SLS allows for precise and minimal waste in the creation of complex shapes. This method is a cost-effective way to produce intricate plastic parts, which were previously impossible. SLS 3D printing is used in medical applications and for other specialized uses.SLS is capable of creating intricate shapes and complex details. SLS is also capable of producing strong parts that have tight tolerances. This type of 3D printer can produce rough prototypes of your products as well as large quantities of prototypes in plastic. SLS is a viable option for 3D-printing and an excellent choice for prototyping.

Using EPRO's Selective Laser Sintering (SLS) has many advantages

Complex Geometries

SLS allows for the creation of parts with fine detail by layering intricate designs. SLS is ideal for prototyping as well as end-use manufacturing.

Bulk Produce Parts Rapidly

Multi-part constructions are possible. SLS scans the laser quickly and efficiently, leading to high productivity at low cost. It increases production and lowers costs.

Low Cost Parts

SLS does not require any post-processing or support structures. SLS is low-cost per part because leftover powder is reused and support structures are eliminated.

Flexible design

SLS allows for the fabrication of complex geometries and moving parts as well as interior components, without any support structures.Flexible design leads to more innovative and creative products.

Excellent Mechanical properties

SLS produces isotropic components with strong bonds. SLS is a great manufacturing method because of its high impact resistance.

Colorblindness

SLS parts are dyeable and colorable. By adding pigments to the raw material powder, SLS printing is able to dye or color parts. Colors can be customized and vibrant.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

SLS Material Options

Our company offers more than 100 thermoplastics. Our SLS materials are available in nylon, polypropylene and glass-filled nylon. They offer a variety of properties to suit your needs. We tailor our materials according to the requirements of our clients.

- PA 11 Black (PA 850)

- PA 12 White (PA 650)

- PA12 Mineral-Filled (PA620-MF)

- PA12 40% Glass-Filled (PA614-GS)

- Polypropylene Natural

- TPU 70-A

Selective Laser Sintering (SLS) Surface Finish Options

The SLS (Selective Lasersintering) process offers many surface finishing options. We offer a variety of finishes, from smooth to textured. SLS can be used for a wide variety of applications, including intricate shapes and complex shapes. SLS allows you to achieve the highest surface finish and ensure that your part is manufactured according to your specifications,improve the functionality and aesthetics of your parts.

Description of Custom surface finishes

Secondary options include a primer or dye color that can be applied as well as taps and inserts.Including:

- Color Dyed

- Media Tumbled

- Nickel Plating

- Coatings

- Painting

- Additional Finishes

Description of Standard Surface Finishes

Bead blast to remove all powder, which leaves a consistent overall texture.

Description of Vapor Smoothing

Significant reduction of surface roughness from 250+ μin RA (as-printed) to 64 – 100 μin RA (after smoothing. Available for PA11 Black.

SLS Design Guidelines & Capabilities

The guidelines for laser sintering include considerations that enhance manufacturing, cosmetic appearance and overall production efficiency. Numerous factors are taken into consideration, including the part orientation, wall thickening, and laser power.

| Description | Notes |

| General Tolerances | +/- 0.010” for the first inch is typical, plus +/- 0.002” for every inch thereafter. |

| Build Area | Build area up to 13" x 13" x 20". Glass filled can extend up to 26" x 15" x 23". |

| Min Feature Size | 0.030" or greater. |

| Standard Layer Thickness | 0.0045" |

| Min Wall Thickness | 0.030" or greater. |

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

Selective Laser Sintering in various industries.

Use Selective Laser Sintering to transform your industry. This cutting-edge technology has transformed many industries from aerospace to health care. SLS allows for high accuracy and repeatability. SLS is a cost-effective, efficient process with a faster turnaround time than traditional machining. SLS allows you to create intricate aerospace components, customized implants and innovative consumer electronics, all with unmatched precision and design freedom. SLS technology opens up limitless opportunities for your industry.

SLS has the following advantages over SLA:

Material properties

SLS 3D printing can be done with plastic, metal, ceramic, and glass powders. Materials made with SLS have high mechanical strength, high heat resistance, and good chemical stability. SLA 3D printers can only print liquid photopolymers, which perform poorly.

Surface finish

The SLS method produces loose, rough prototypes, while the SLA method produces smooth, detailed surfaces. The loose surface finish of SLS can still be enhanced with various post-processing techniques. SLS-printed objects can be polished, sanded, and coated to improve their appearance.

Glue bonding strength

The porous surface of SLS prints makes the adhesive penetrate deeper and create a stronger bond between layers than SLA 3D printing.

Environmental resistance

Temperature, humidity, chemical corrosion are not a problem with SLS 3D printed prototypes. Hence, SLS 3D printed prototypes are suitable for applications where multiple environmental factors are expected, such as automotive parts. Moisture and chemical attack make 3D printed SLA prototypes prone to becoming soft and deformed above 38°C.

Machining performance

SLS can be milled, drilled, and tapped easily during processing. The thermoplastic materials used in SLS machining are extremely strong and durable. While SLA 3D printing should be handled carefully to avoid damage to the parts.

SLS (Selective laser Sintering) Tips

SLS is a versatile tool for both production and prototypes.

SLS is a powder-based process, which means it produces a rougher surface finish. It also has lower resolution. Avoid large flat surfaces as they are more prone to warping. Ribs should be used to support SLS parts with flat surfaces. The ribs should be evenly spaced and perpendicular with the flat surface. The ribs must be thick enough to support the part and make it cost-effective for printing.

Visit our Selective Laser Sintering (SLS) workshop

SLS technology transforms raw materials into intricate, high-quality components with precision and efficiency. With SLS technology, you can create complex shapes with incredible accuracy. See how SLS can reduce production costs and improve efficiency. We offer cutting-edge SLS machines run by technicians trained to deliver optimal results at our SLS workshop. See first-hand how laser sintering enables complex geometries and functional prototypes to be created with unparalleled precision.

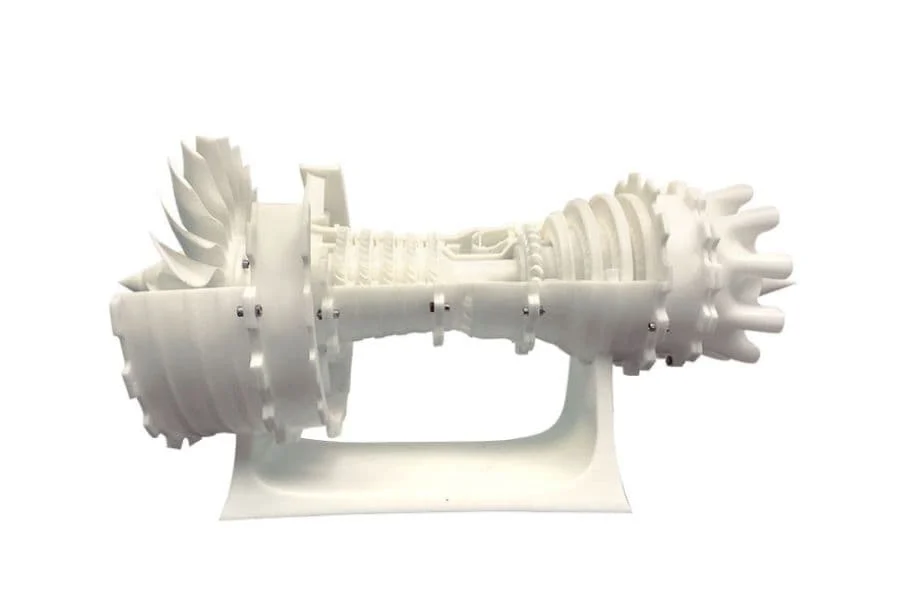

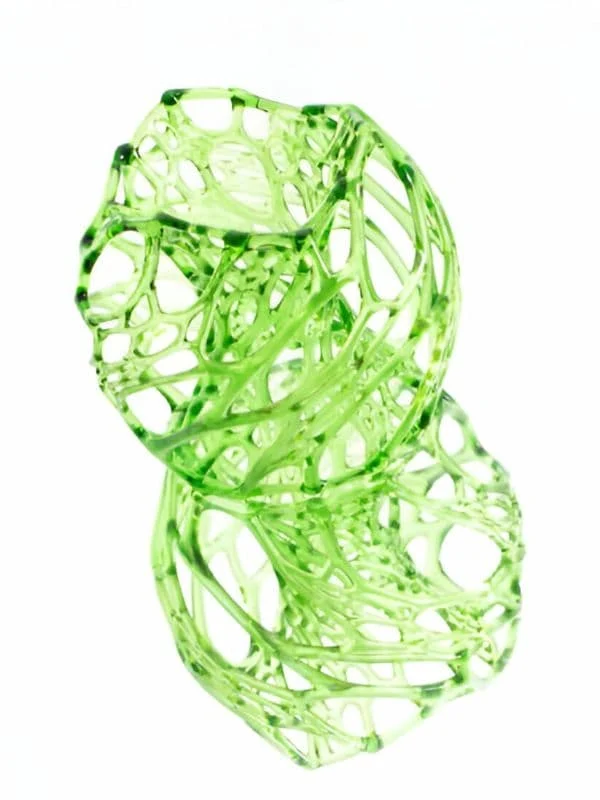

Gallery Of Selective Laser Sintering (SLS) Parts

Check out our display of SLS Parts. At EPRO, you can confidently get the best SLS parts!