Digital Manufacturing for Automotive Development

Exactly how do EPRO's automotive parts get made?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

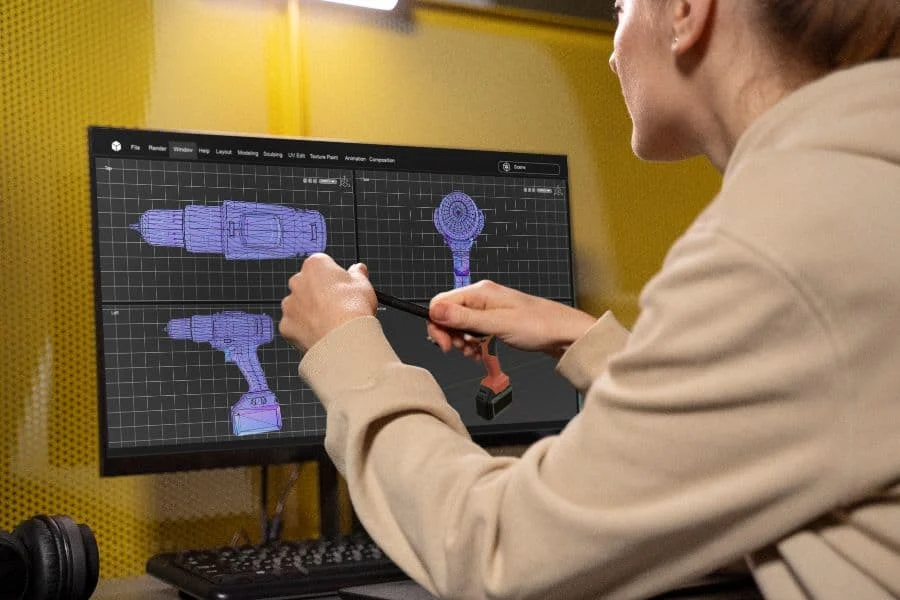

Rapid Prototyping

- Rapid prototyping and iterations in production materials can help mitigate design risk without sacrificing development speed. Automobile production methods become more efficient and reliable by utilizing this approach, which allows for quick testing and refinement of design concepts.

Quality Inspections

- A variety of quality documentation options are available to validate part geometry. PPAP, FAI, and digital inspections are available. As part of the automotive industry, these quality inspections ensure that the part geometry meets specifications and standards. In this way, the quality and safety of the vehicles can be maintained.

Tooling and Fixtures

- Custom fixturing can improve manufacturing processes by automating and streamlining component assembly. In the automotive industry, custom fixturing can enhance efficiency and precision during assembly, thereby reducing errors and increasing productivity. As a result, time and costs are saved as well as quality is consistently maintained.

Mass Customization

- Develop low-volume manufacturing processes to enable a greater variety and customization of automotive features. As a result, automotive manufacturers are able to meet the evolving demands of modern drivers, providing a wide range of customizable features tailored to their preferences. Customer satisfaction is increased and vehicle-driver connections are strengthened.

Automotive Industry Prototyping and Production Solutions

New products in the automotive industry require reliable solutions. You can count on us for durable, high-performance prototypes and production parts. We offer a variety of production stages. We design custom prototypes and production parts for the automotive industry to ensure reliability and optimal performance. The solutions we provide seamlessly integrate with complex automotive systems and processes, whether they are engine components, electrical systems, or vehicle interiors.

Prototyping

A prototype is essential for testing usability, functionality, and scalability. Also, prototypes are useful for testing design concepts and gathering feedback. Before the product is manufactured, you should test your designs, make iterations, and create prototypes.

At this stage, prototypes will be created based on your product’s requirements. Parts like the final product will be made with low-cost materials. Test prototypes for functionality, performance, and reliability. By examining specifications metrics and functional testing, we can identify potential design flaws. Our advanced technologies allow us to deliver prototypes quickly.

- Design and material iteration in a rapid manner

- Complex Geometry Prototypes

- Comparison of models with final products

Engineering Validation and Testing (EVT)

Create precise functional prototypes quickly and easily to meet all performance requirements. Before the product enters production, EVT helps identify potential issues. It ensures cost-effectiveness, quality, and reliability.

You can easily identify all design risks with our functional prototypes. It saves time and money in the long run. You can test your product’s usability with our prototypes. Lastly, our prototypes are scalable, so you can quickly customize them. It may take several iterations to meet all functional requirements.

- Manufacturing precision parts

- Support for reliable design and engineering

- Designing with optimized material properties

Design Validation and Testing (DVT)

A wide range of materials and surface finishes are available for testing part functionality, performance, and appearance. Get detailed results by using DVT’s advanced capabilities. Make sure your parts are reliable and durable by testing them with DVT.

Analyzing the final appearance and feel of the component is the purpose of this stage of production. A design error or defect is checked at this stage. Safety standards and requirements are also tested.For consumer and market testing, we create parts with end-use functionalities.

- Testing of high-quality parts for consumers and markets

- Validation of performance and appearance

- A durable and high-quality finish on the surface

Production Validation and Testing (PVT)

Make sure your design is ready for full-scale production with production-grade manufacturing capabilities and advanced quality control. PVT ensures that your product meets all quality requirements and standards. A reliable design can also be reproduced consistently. Additionally, PVT ensures that the production process is efficient and scalable.

Make sure your production goals are met during DVT. Testing the design’s performance and capability is crucial. Using the results can also help identify failures and issues before they become costly. During this stage, we will set up the supply chain and solidify manufacturing processes. The following steps can help you test and optimize your design.

- Delivery of high-quality production parts in a timely manner

- Process verification for manufacturing

- Tooling for low-volume production

- Check the functionality of production-ready parts

Mass Production

Test products before mass producing end-use components. Rapid product delivery with precise quality requirements. Automated production processes ensure accuracy and speed. Operational costs are reduced while quality standards are maintained. Utilize the latest technologies to stay ahead.

With our advanced manufacturing process and engineering expertise, we can produce your parts. Our top priority is providing high-quality parts at low prices. We test our processes thoroughly to ensure accuracy. Low costs and lead times are achieved by our professional technicians. With our engineering expertise, we guarantee the highest quality parts and service.

- Customized end-use parts of the highest quality

- Precision machined parts require tight tolerances

- Improved Surface Requirements through Secondary Operations

- Controlling and inspecting quality rigourously

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

Automotive Applications

To survive and flourish in the turbulent automotive industry, your company must become agile. The same is expected of your suppliers. With a variety of manufacturing solutions, we meet the dynamic requirements of the automotive industry, from precision engine components to custom interior trim.

EPRO offers contract manufacturing services specific to the automotive industry that meet the needs and requirements of automotive companies. You can rely on EPRO to speed up new product development and create automotive prototypes with precision engineering and efficient production processes.

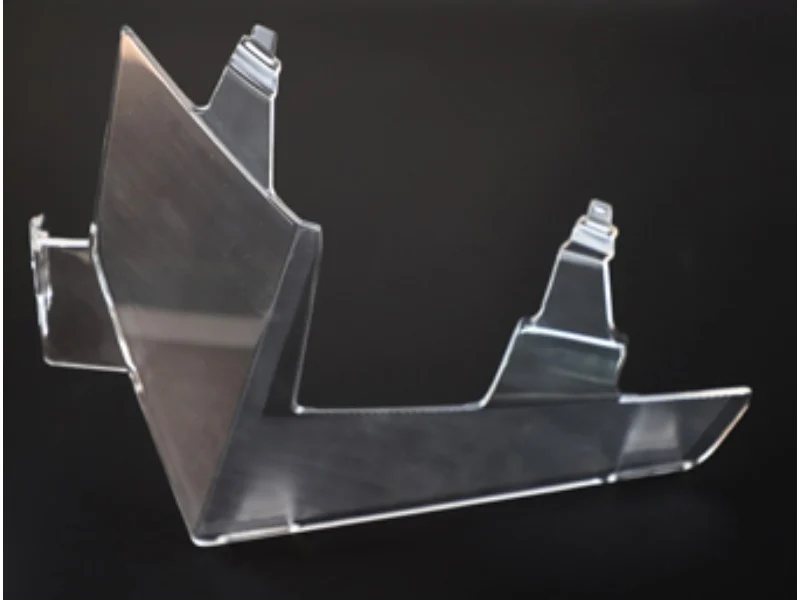

- Fixtures

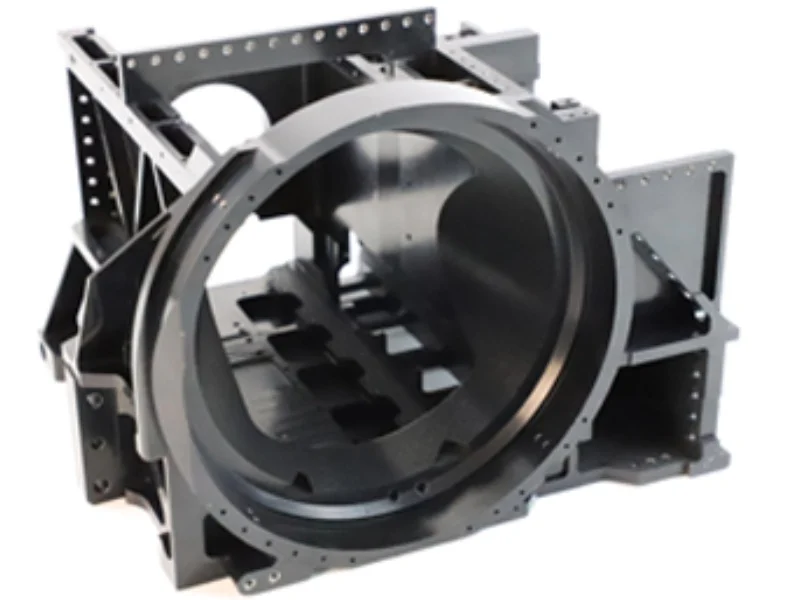

- Enclosures and housings

- Plastic dash components

- Aftermarket parts

- Armatures

- Lenses and lighting features

- Support for on-board consumer electronics

- Prototypes

- Replacement parts

- Legacy/obsolete parts

- Electric vehicle and battery parts

- Jigs and fixtures

- E-bike and scooter parts

- Custom body parts

- Commercial/utility vehicle parts

- Dashboard and steering wheel components

- Lighting and lenses

- Bumpers

- Engine parts

- Assembly line components

- Exterior trim body parts and panels

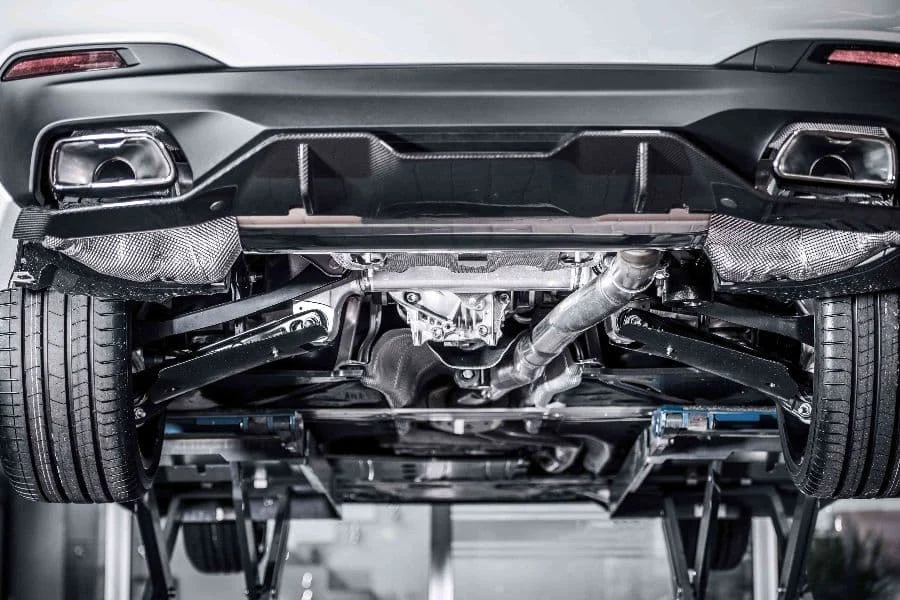

- Undercar aero shields and panels

- Fluid tanks and plastic housings

- Underhood components

- Wiring harnesses

- Interior trim

- Mounts and brackets for in-dash navigation and entertainment systems

- Manufacturing tooling and fixtures

- Electric vehicles

- Autonomous vehicle sensors

- Automotive manufacturing line fixtures

- Electric bikes and scooters

- Infotainment systems

- Utility vehicles

- Commercial vehicles

What is the target audience for our services?

- Manufacturers of automotive products

- Auto component plants that manufacture OEM components

- Assembly plants for OEM vehicles

- Studio for OEM design

- Automobile OEM parts manufacturers on their own

- Suppliers at Tiers 1 and 2

- Technologies for autonomous driving

- Automotive parts manufacturers

- Heavy equipment manufacturers in the industrial sector

Automotive Manufacturing Capabilities

EPRO offers wide range of manufacturing processes for Automotive prototypes and production parts.

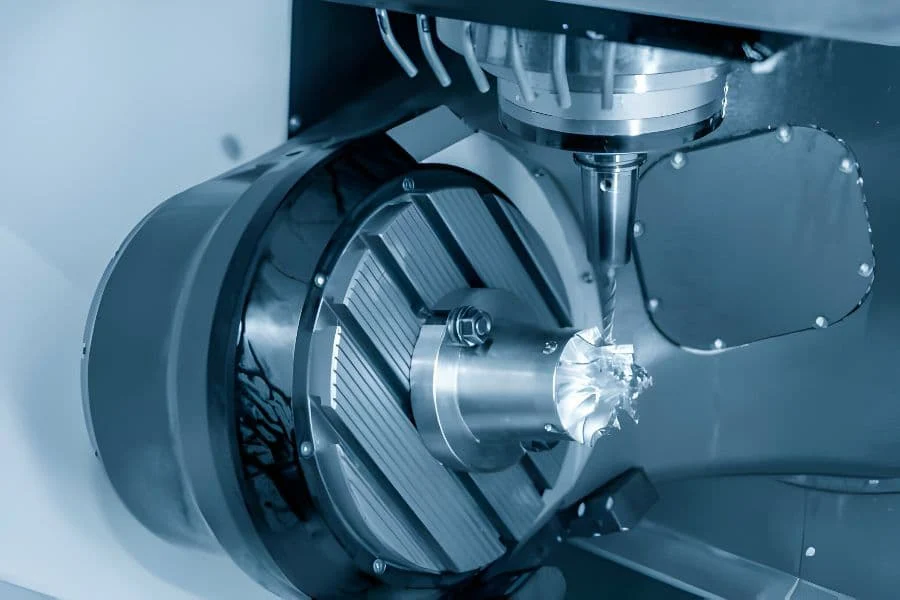

CNC Machining

Crafting precision engine components and transmission parts for high-performance vehicles.

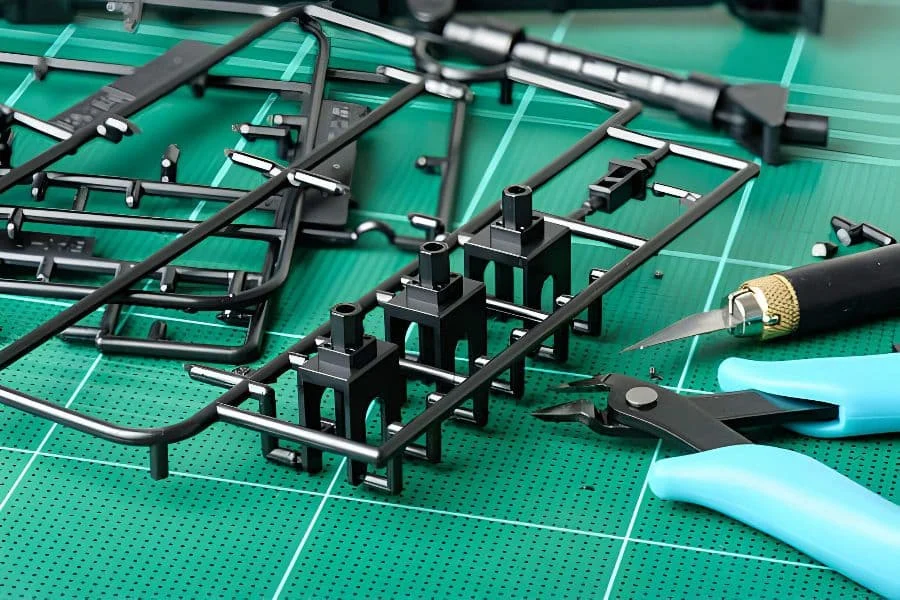

Injection Molding

Producing durable plastic interior and exterior components for automotive assemblies.

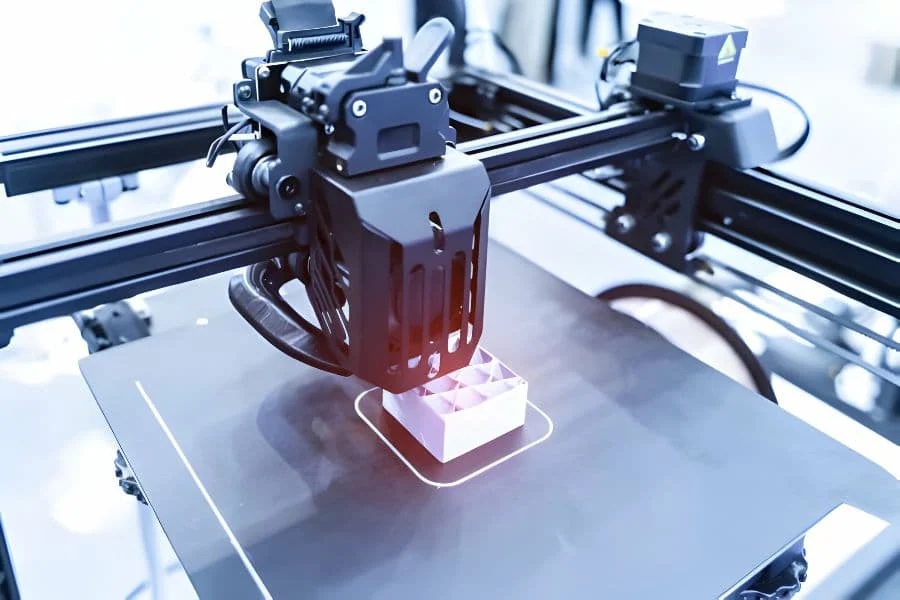

3D Printing

Prototyping customized car parts and accessories, enabling rapid design iteration and innovation in automotive engineering.

Sheet Metal Fabrication

Fabricating structural components and body panels for automotive frames, ensuring strength and safety in vehicle construction.

Materials for Automotive manufacturing

Discover top-quality automotive materials. Our products provide durability and efficiency, from robust steel to lightweight aluminum to advanced titanium. For interior components, PA (Nylon) and PMMA are versatile, while silicone seals provide superior performance. With these materials, we are able to meet the demanding demands of our industry every time, ensuring durability, precision, and efficiency.

Materials for Automotive manufacturing

| Image | Material | Best Tech. | Benifits | Sample Parts |

|

Steel | CNC machining, rapid tooling | Strong, corrosion-resistant, range of grades | Brake components, engine components |

|

Aluminum | CNC machining, rapid tooling, sheet metal | Machinable, strong, range of grades | Cylinder heads, manifolds, Ductwork, housings, bus ducts |

|

Titanium | CNC machining, SLM 3D printing | Lightweight, temperature-resistant | Engine valves, axle shafts, pipes, nuclear waste storage, pumps, turbines |

|

PA(Nylon) | CNC machining, SLS 3D printing, injection molding | Strong, smooth surface finish | Peripheral engine parts, covers and housings |

|

PMMA | CNC machining, injection molding | Transparent, shatter-resistant | Lighting components |

|

|

Silicone | Liquid silicone injection molding | Durable, flexible, biocompatible, inert | Seals, cover assemblies, Fluid management devices, respiratory devices |

Suitable Finishes for Automotive industries

Enhance automotive components with precision finishes. From the sleek aesthetics of painted surfaces to the protective qualities of anodized coatings, our services cover every aspect. Consider sanding and polishing for interior trim, while nickel plating ensures durability for exterior hardware. With options like powder coat and chromate conversion coating, we tailor finishes to meet your specific needs.

| Image | Item | Applicable To | Feature | Color | Thickness |

|

As machined | Metals & Plastics | Tool marks visible | N/A | N/A |

|

Polishing | Metals & Plastics | Brushed & gloss mirror surface | N/A | 0.02-0.05mm removed |

|

Sand, Bead Blasted | Metals & Plastics | matt or satin surface | N/A | N/A |

|

Painting | Metals & Plastics | Matt, gloss, texture | colors can be matched as needed | 0.05mm to 0.1mm |

|

Powder coating | Metals | Matt, gloss, texture | colors can be matched as needed | 0.05mm to 0.15mm |

|

Anodization | Aluminum | Tool marks visible, Smooth, Matt & Gloss | colors can be matched as needed | 0.002mm to 0.04mm |

|

E-Coating | Metals | Matt & Gloss | Black | 0.015mm to 0.035mm |

|

Nickel Plating | Metals | Gloss | Silver | 0.004mm to 0.05mm |

|

Chromed Plating | Metals & Plastics | Satin & Gloss | Silver | 0.001mm to 0.3mm |

|

Zinc Plating | Metals | Gloss | Silver & Black | 0.005mm to 0.2mm |

|

Chromate Conversion Coating | Aluminum | Tool marks visible, Smooth and Matt | Clear/ slight yellow tint | 0.25-1 um |

Put your parts into production today

All information and uploads are secure and confidential.

Tour Our 5 Axis Machine Shop

Check out our incredible line of well-functioning 5-axis machining centers ranging from the best 5-axis horizontal machining center to top-notch vertical machining centers. These are ideal facilities for manufacturing components for various industries. We combine advanced technologies with skilled technicians to deliver results to suit your needs perfectly.

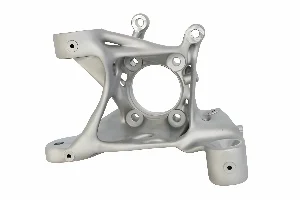

Gallery Of Automotive Parts

Check out our display of Sheet Metal Parts. At EPRO, you can confidently get the best Sheet Metal parts!