3D Printing Services

3D Printing: What Is It?

As an additive manufacturing process, 3D printing involves layering multiple materials to create a part, also known as rapid prototyping. The manufacturing process has been revolutionized by 3D printing, which allows companies to produce complex parts quickly and at a low cost.

Rapid prototyping 3D printing transforms great ideas into successful products quickly, easily, and cost-effectively. Using 3D printing, intricate shapes can be created with high accuracy, and parts can be customized. As a result, this technology is also environmentally friendly, since it uses less energy and raw materials. 3D printing not only confirms the design, but also identifies issues early on and gives feedback directly on the design, preventing costly changes once production begins. Overall, 3D printing is an invaluable tool for businesses that need to produce prototypes quickly and cost-effectively.

3D Printing Advantages at EPRO

Quick turnaround

Parts can usually be shipped in a day or less, allowing for quicker iterations. Developing and prototyping products faster with 3D printing saves time and resources.

Stability

It improves impact strength, flexibility, and environmental resistance. 3D printed parts are more durable, as they can withstand impact and environmental factors. This makes them ideal for prototypes and end-use parts in many industries.

Geometric complexity

The 3D printing process makes geometric shapes easier to construct, allowing complexity without raising costs. Geometries with complex shapes can be easily created using 3D printing.

Precision

Precision can be achieved through 3D printing. Due to its precision, 3D printing can produce intricate, detailed parts. Precision measurements and fine details are critical in industries like aerospace and healthcare.

Produced parts

EPRO 3D printing produces parts efficiently and accurately, improving productivity. Material waste in manufacturing is reduced by removing traditional tooling.

Flexibility

It’s easy to make dozens of production pieces with 3D printing. 3D printing is scalable. Small batches or large production runs can be produced efficiently and effectively with 3D printing.

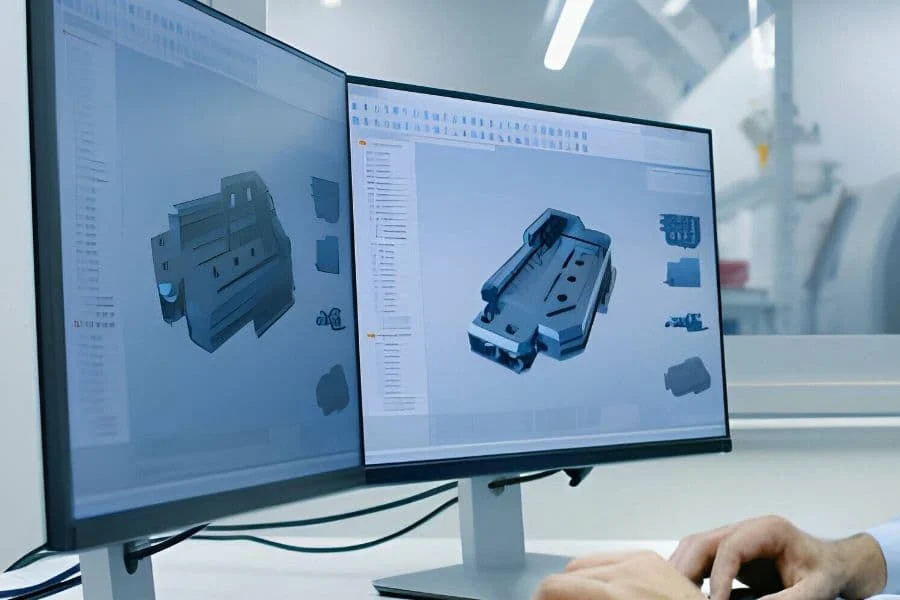

EPRO 3D Printing: Why choose us?

Exceptional Quality

According to your application’s requirements, we will also determine optimal part orientation. Our engineering team ensures unmatched precision and durability of 3D-printed parts. With this attention to detail, your product will perform optimally.

Quotation Consultation

Dedicated quality and process engineering teams are responsible for our industry-leading tolerances. We utilize Consultative Quoting in 3D printing so that we can optimize the tolerances and surface finish quality for the best results for each project.

Various materials available

We 3D print parts from thermoset resins, thermoplastics, and metal powders that are suitable for various industries. As well as heat treating and secondary machining, plating, painting, and dyeing, we offer a variety of post-processing options.

Productivity and scale

Our 3D printers can produce metal and plastic parts. Our facility’s scale and production capabilities enable us to meet your needs. Keep your projects on schedule with our quick and efficient deliveries.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

The 3D Printing Solution we offer

Specialist Manufacturing

Our products are certified to ISO 9001, ISO 13485, and EN 9100:2018, ensuring the highest quality. Specialist quality control and assurance is what we do. Using our expertise in quality control and assurance, we provide exceptional 3D printing services to specialist manufacturers.

3D Printing for Small Scale Production

Materials and technologies we offer offer our customers a wide range of manufacturing solutions. 3D printing makes small scale production efficient and cost-effective. It is ideal for prototyping and customization due to its high precision.

3D Printing for a Prototype

You can count on us for all your prototyping needs, from simple prototypes to fully finished space models. We produce detailed prototypes quickly using 3D printing technology, so you can visualize your product before production.

Explore EPRO's

Additive Manufacturing Solutions

Stereolithography (SLA)

Many design and engineering teams use stereolithography as an additive manufacturing technology. Fast, affordable, and widely available. Moreover, complex shapes and geometries can be achieved using this technology. Its high-quality surfaces and accurate detailing make stereolithography an ideal option for prototyping and low-volume production.

Selective Laser Sintering (SLS)

SLS is a process that uses a CO2 laser to fuse layers of nylon-based powder for the construction of thermoplastic parts. Using SLS, complex shapes and parts with intricate details can be created. Using SLS, parts with complex geometries can be produced with high accuracy and at an affordable cost. For this reason, SLS is an invaluable tool when it comes to producing complex parts and components.

Multi Jet Fusion (MJF)

With Multi Jet Fusion, fusing and detailing agents are selectively applied across nylon powder, which is then fused by heating elements into a solid functional component.

PolyJet

PolyJet involves spraying liquid photopolymer droplets over a build platform and curing them in layers to form elastomeric parts.

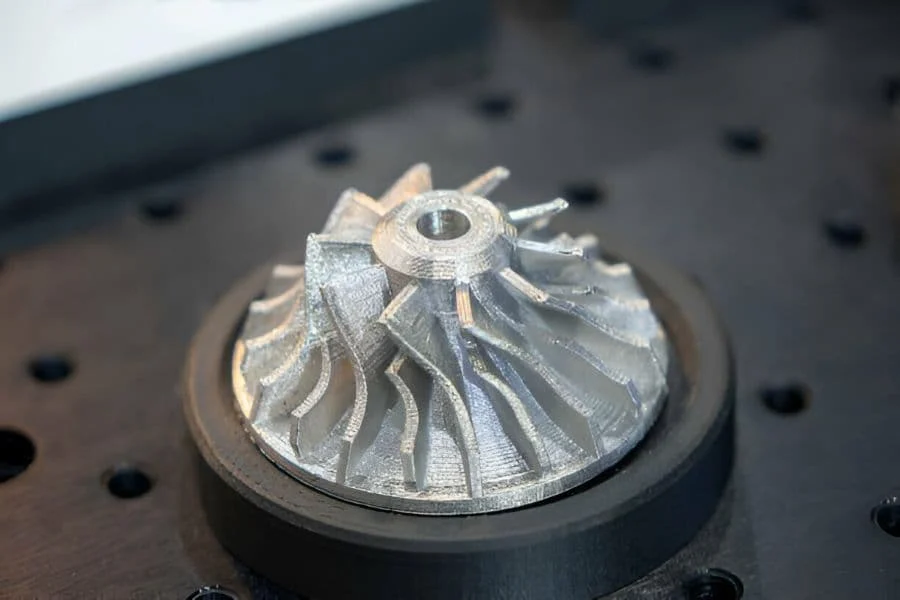

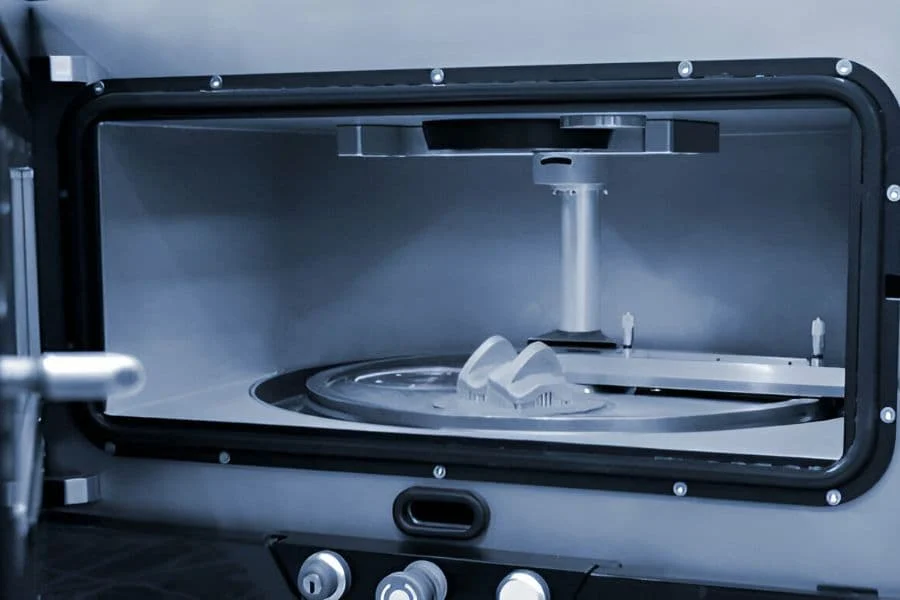

Metal 3D Printing

With direct metal laser sintering (DMLS), fiber lasers are used to draw onto atomized metal powder, welding the powder into a dense metal part.

Materials that can be used for 3D printing

Below are descriptions of each process, so that you can see which one best meets the needs of your application.

Plastic

- ABS

- PA (Nylon)

- Polycarbonate

- Polypropylene

Elastomers

- Digital photopolymer

- TPU

- True Silicone

Metals

- Aluminum

- Cobalt Chrome

- Inconel

- Stainless Steel

- Titanium

3D Printing material view

ABS

PMMA

PA(Nylon)

TPU

Aluminum

Stainles Steel

Compare the capabilities of each process below to see what fits your application's requirements.

| Material | Max Part Size | Min Feature Size | Tolerance | |

| Stereolithography(SLA) | ABS,Polycarbonate,Polypropylene,Silicone | 29 in. x 25 in. x 21 in. | 0.0025 in. | ±0.002 in. |

| Selective Laser Sintering(SLS) | Nylons,Polypropylene,TPU | 19 in. x 19 in. x 17 in. | 0.030 in. | ±0.010 in. |

| Multi Jet Fusion | Nylons | 11.1 in. x 14.9 in. x 14.9 in. | 0.020 in. | ±0.012 in. |

| PolyJet | Elastomer (30A to 95A) | 19.3 in. x 15.4 in. x 7.9 in. | 0.012 in. | ±0.005 in. |

| Metal 3D Printing | Aluminum,Stainless Steel (17-4, 316L),Titanium,Inconel,Cobalt Chrome | 9.6 in. x 9.6 in. x 13.0 in X Line: 31.5 in. x 15.7 in. x 19.7 in. | 0.006 in. | ±0.003 in |

3D Printing Surface Finishes

Surface treatments offered by EPRO enhance your product’s aesthetic appeal. We also offer surface finishing options such as sanding and polishing to remove any roughness or visible layers from the 3D printed parts. As well as offering painting and coating services, they improve the mechanical qualities of prototypes and production parts through these efficient secondary operations.

Description of Custom surface finishes

Soft-touch paint, clear part finishing, painting, masking, color matching, decals/graphic, and texture finishes are available.

- Clear Coat

- Painting

- Plating

- Dyeing

- Decaling

- Polishing

- Heat Treatment

- Machining

Description of Unfinishes

Dots, or standing “nibs,” remain evident on the bottom of the part from the support structure remnants.

Description of Natural Surface finishes

Supported surfaces are sanded down to eliminate the support nibs.

Description of Standard Surface Finishes

Supported surfaces are sanded, and the entire part is finely blasted for a consistent look. Note that the layers are still present.

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

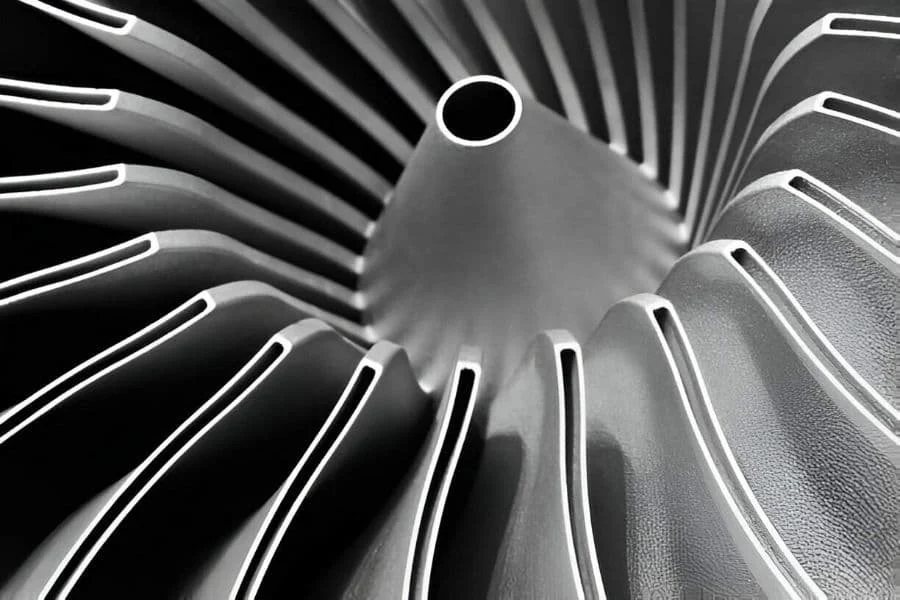

Applications of 3D printing in various industries

With 3D printing revolutionizing industries, industries have been forever changed. It reshapes the future of flight by crafting intricate prototypes and lightweight components. It is used to fabricate personalized implants in healthcare, improving patient care. For innovative designs, automotive uses rapid prototyping, while consumer goods use customized manufacturing. With 3D printing, companies can create complex designs with speed and precision.3D printing sparks innovation across a variety of sectors and offers tailored solutions.

Here are some 3D printing tips

Ensure that your designs are optimized for additive manufacturing, emphasizing geometry and support structures. Material selection should take into account strength, flexibility, and precision. Make use of layer thickness to strike a balance between speed and detail. Consider post-processing techniques to achieve a flawless finish. Check the accuracy and performance of your designs using simulation tools. Work with our skilled team to take your concepts from concept to reality – using 3D printing to transform them into tangible, high-quality objects.

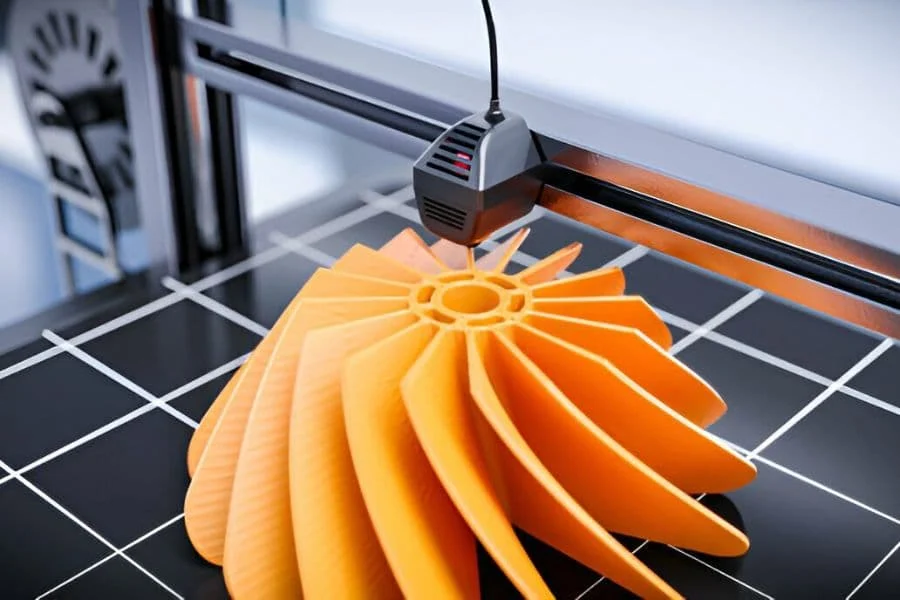

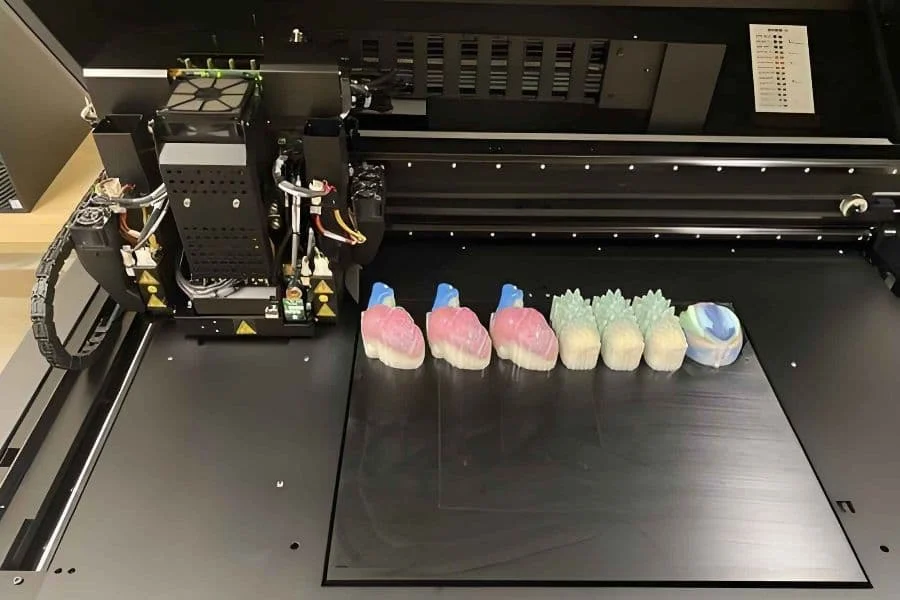

Visit our 3D printing workshop

Our 3D printing workshop is a cutting-edge facility where innovation and precision come together. Discover how state-of-the-art printers craft intricate designs quickly and accurately. With our team of experts on board, the process is seamless, from the beginning to the end. We offer a variety of materials that can be tailored to meet your specific requirements. Discover how 3D printing revolutionizes manufacturing, pushing boundaries and unlocking limitless possibilities. We invite you to join us on a tour to discover how fabrication will be done in the future.

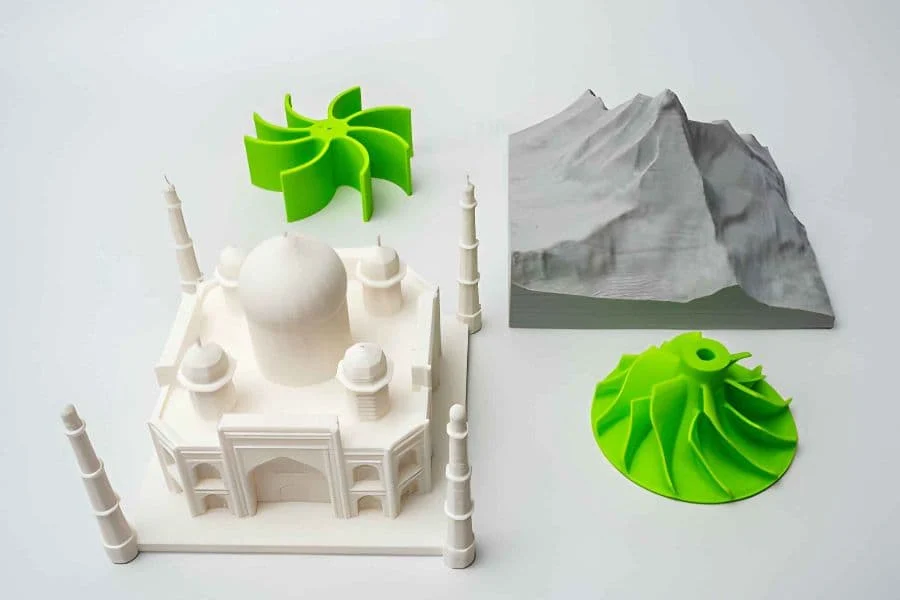

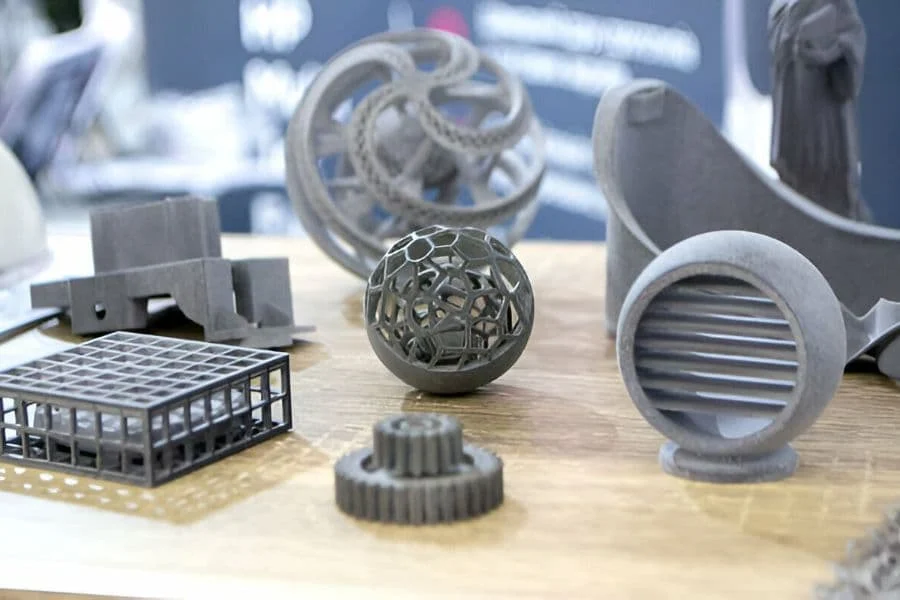

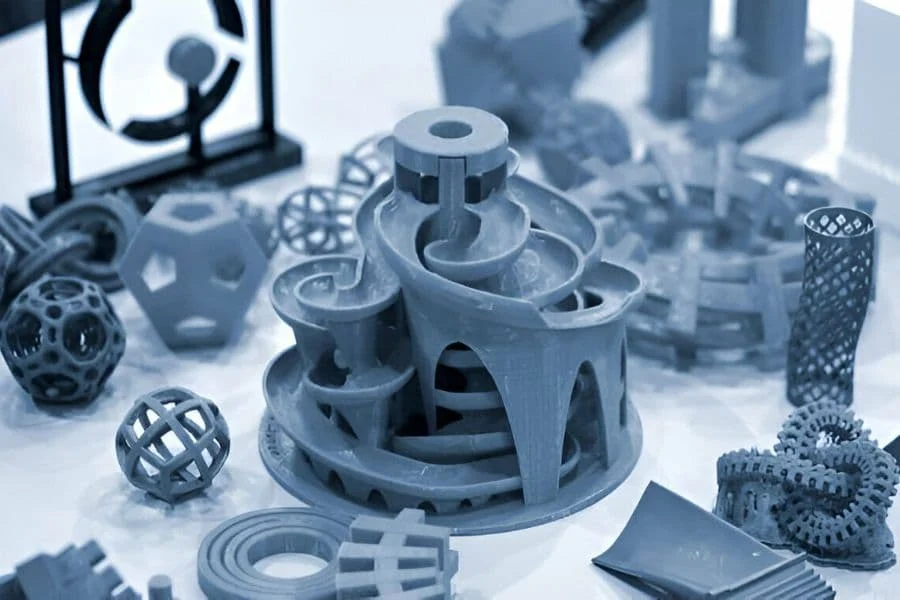

Gallery Of Plastic 3D Printed Parts

Check out our display of 3D Printed Parts. At EPRO, you can confidently get the best 3D Printed parts!