Your ISO-Certified CNC Precision Machining Factory

- Manufacture Factory Directly-Price & Quality Guaranteed

- Start Customised With NO MOQ limited

- Rush Delivery Supported-Guaranteed by Invalid DateTime

Customer Satisfaction

Customer Served

Countries

Components

Years Experience

ABOUT US

Epro Rapid is your trusted one-stop services supplier, established in 2015 with a mission to help all your on-demand manufacturing needs.

From design to reality, from prototype to production, from simple to complex, we’re your ISO Cert 9001:2015 manufacturing partner.

Epro Rapid specialized in supply of manufacturing solutions via a wide range of products, with economic way, professional services, fast turn-around, quick response to turn your concepts into products.

Our Advantages

Our mission is dedicated to meet our customers high quality requirement, will test every projects according to our ISO 9001 certified quality management.

Also have a network of more than 200+ manufacturing partners, to help with all your parts from one source. No MOQ, whether you need a prototype to verify a design, low volume production or mass manufacturing for end products, our engineering team will provide the best solution for you.

Our manufacturing Capabilities

At EPRO-Rapid, a leading CNC precision machining factory, reliability meets speed. Transform your concepts into tangible parts within days with our top-tier rapid prototyping services. Trust us to bring your designs to life swiftly and efficiently.

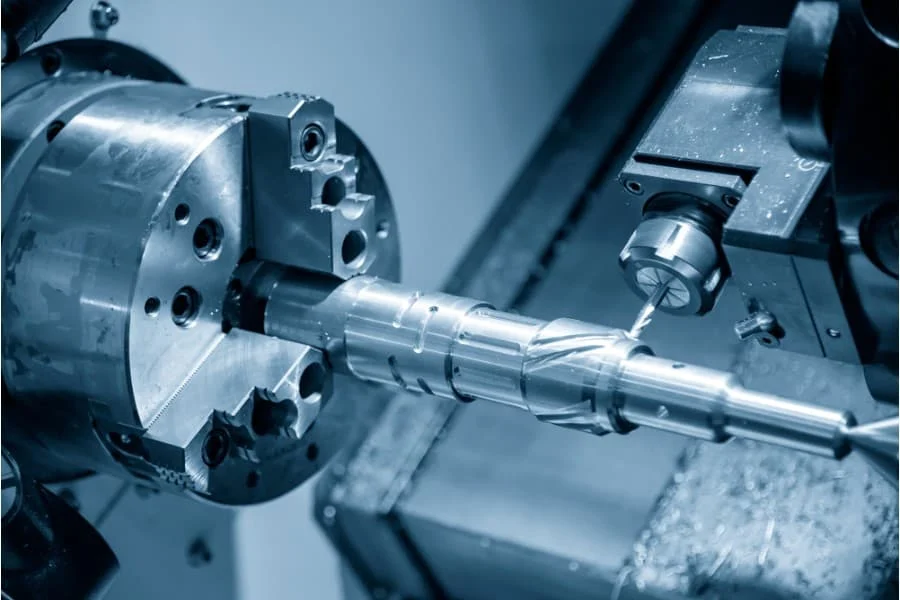

CNC Machining

We are able to offer many different kinds of prototypes and production parts by CNC milling and turning as a primary choice in the ordinary course workflow for our CNC machining factory.

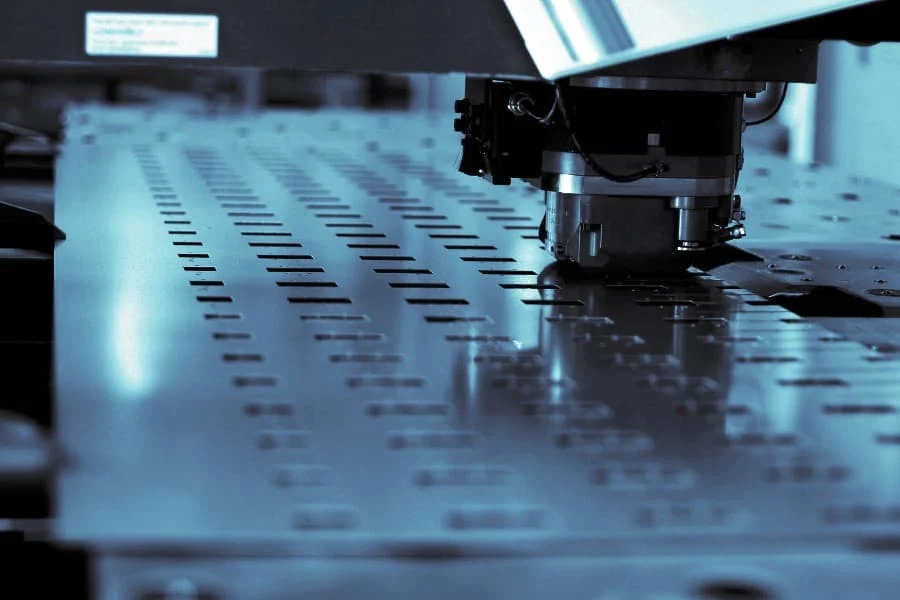

Sheet Metal Fabrication

We are a professional Sheet Metal Components Factory and we provide quality metal manufacturing services like Laser Cutting, Bending, Stamping, Spinning, Punching & Welding.

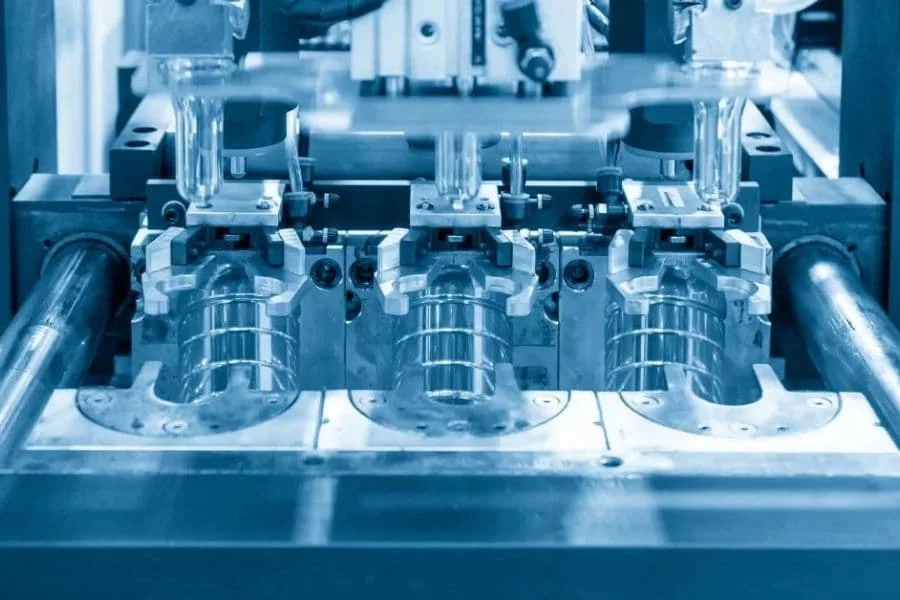

Plastic Injection Molding

We offer comprehensive plastic injection molding service including both low-volume prototype moldings and mass production productions to ensure all your manufacturing needs are met.

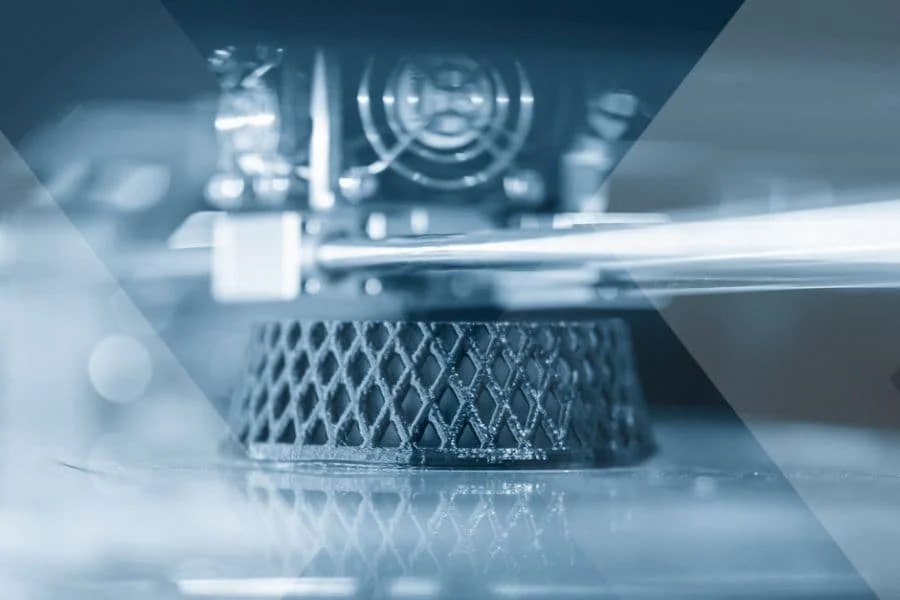

3D Printing

Epro-Rapid are an intelligent 3D printing factory and produce components which can be used as meaningful prototypes or production parts.

Why you can trust EPRO

Precision and Quality

A dedicated CNC precision machining facility ensures high accuracy and exceptional quality, producing trustworthy parts that conform with your exact requirements every time.

Fast Turnaround

Rapid Prototyping & Fast Turnaround Times Ideas to Solid parts in Days – Less Downtime, Faster Time-to-Market

Cost-Effective Solutions

We provide cost-effective manufacturing solutions competitively priced with efficient process and without compromising on the quality or delivery time.

Comprehensive Capabilities

Our range of capabilities include CNC machining, sheet metal fabrication, plastic injection molding, and 3D printing.

Prototypes and Parts Made Easy

Enjoy standard 3-day lead times for simple parts ranging from 10 mm x 10 mm to 200 mm x 200 mm. Upload your design to check eligibility.

01 Upload CAD File

02 Quote & Design Analysis

03 Order Confirmation

04 Parts Shipped

Work With Numerous Industries

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Aerospace & Defense

Our CNC machining excellence thrives in the dynamic world of aerospace and defense. This we do by crafting essential aerospace parts that are necessary to the world of aviation and national security, ensuring innovation and reliability in every component.

Automotive

This is precision engineering that has been designed specifically for the automotive industry. Advanced Automotive CNC Machining In EPRO-Rapid, we utilize state of the art automotive cnc machining to manufactures thousands of components that go in every single vehicle making its way down the roads today.

Medical Devices

Enter into the world of cutting-edge medical precision manufacturing. To facilitate these medical advances, EPRO-Rapid harnesses cutting-edge applications of the new technology we of 3D printing to create customized tools and devices for a very large health care field.

Robotics & Automation

Welcome to the realm of robotics and automation, where precision engineering meets high-tech design. EPRO-Rapid uses CNC machining automation to fabricate parts that help incorporate new ideas and increase progress in the robotics and automation sector.

Consumer Products

Step into the world of consumer electronics and household appliance precision manufacturing. With Epro-Rapid you get cutting-edge sheet metal fabrication plus 3D printing consumer products, together enabling the most dynamic and specialized products for the consumer market.

How did our Client Said

Real Reviews From Our Customers

Richard P.

Our partnership with EPRO has been instrumental in enhancing our production efficiency. Their CNC machining capabilities and attention to detail have ensured the timely delivery of high-quality automotive parts. Highly recommended for their reliability and expertise.

Billy D.

Thrilled with the seamless integration of components supplied by this machining expert. Their attention to detail and commitment to tight tolerances have greatly contributed to the success of our advanced robotic systems. Precision that defines excellence!Thanks EPRO-MFG team!

Theresa W.

Choosing EPRO for our manufacturing needs was a game-changer for us. Their expertise in precision machining and dedication to meeting strict regulatory standards have allowed us to bring our innovative medical devices to market faster and with confidence. Grateful!

Edward S.

Working with EPRO has been a breath of fresh air in the aerospace industry. Their commitment to quality and their ability to deliver complex components on time have exceeded our expectations. Trustworthy, professional, and highly skilled, they are now our go-to partner for machining needs.

Choose Your Solutions

Rapid Prototyping

Rapid prototyping is a process focused on quickly creating functional or conceptual models to test and validate design ideas. Using technologies like 3D printing and CNC machining, it enables engineers to iterate designs rapidly, reduce development risks, and accelerate product innovation. This approach is ideal for early-stage development, as it requires minimal tooling and supports high design flexibility, though the resulting parts may not always match final production quality.

Low-Volume Manufacturing

Low-volume manufacturing focuses on producing small batches of parts—typically from dozens to a few thousand—using methods like CNC machining or injection molding. It is ideal for bridge production, pilot runs, or customized products, offering faster turnaround and lower tooling costs compared to mass production. This approach enables rapid response to design changes and reduces inventory risks, though unit costs are usually higher than large-scale manufacturing.

On-Demand Production

On-demand production is a flexible approach where parts are made only as needed, using technologies such as CNC machining and 3D printing. This model minimizes inventory, supports quick design changes, and reduces waste, making it ideal for businesses with variable demand or frequent product updates. While it offers high responsiveness, production speed and cost per part may vary depending on order size and complexity.Let's contact EPRO-Rapid for the assistatnt today :)

HAVE A QUERY?

We’ve mapped out a few answers for you right away.

What type of services does EPRO-Rapid Precision focus on?

We provide CNC machining, milling, turning & 5-axis CNC machining for the manufacturing of complex and intricate components as well as all other secondary processes like extrusion & molding, vacuum casting, 3D printing, die casting,surface finishing and sheet metal fabrication if you need.

Which industries does EPRO-Rapid Precision serve?

EPRO-Rapid Precision caters to a wide array of sectors, including aerospace & defense, automotive, medical devices, telecommunications, robotics & automation, and consumer products. Our expertise ensures high-quality solutions tailored to meet the specific needs of each industry.

How does EPRO-Rapid Precision ensure the quality of parts produced?

At EPRO-Rapid Precision, we use a combination of experienced engineering staff, top-of-the-line CNC machines and inspection processes to ensure the parts we build are of the highest quality. In order to ensure each component meets the highest standards, we use cutting edge tools like CMMs (Coordinate Measuring Machines) and other high-precision quality check machines. The stringent quality-assurance we uphold signifies every component is made to precise standards and operates dependably within its designed application.

Is EPRO-Rapid an ISO Certified Company?

Yes, EPRO-Rapid is proud to be an ISO 9001:2015 certified manufacturer. This certification underscores our commitment to maintaining high-quality standards in every project and for every customer. Our ISO certification ensures that we consistently meet customer and regulatory requirements through our robust quality management system.

Can I get a sample before full production?

Absolutely! At EPRO-Rapid, we understand the importance of validating your design before full production. For processes like injection molding, we provide an initial T1 sample of your parts. Additionally, we can offer further samples as needed to ensure everything meets your specifications before moving into full-scale production.

How does intellectual property protection work with EPRO-Rapid?

First of all, the protection of your intellectual property is fundamental to us at EPRO-Rapid. Your design is always 100% secure and we take you privacy seriously. And, to provide you with peace of mind before the start of any project we ready to sign a non-disclosure agreement (NDA) Rigid security procedures and in-house regulations also prevent unauthorized access to your sensitive data, protecting the IP that is created at every stage of manufacturing.

What are the typical lead times for projects at EPRO-Rapid Precision?

Typical lead times at EPRO-Rapid Precision range from 5 to 25 days, depending on the complexity and quantity of your parts requirements. We offer flexible delivery options to meet your needs, including express courier services for urgent projects, air freight for faster international shipping, and sea freight for larger, less time-sensitive shipments. Our goal is to ensure timely delivery, tailored to your specific schedule and logistical preferences.

Does EPRO-Rapid Precision offer international shipping?

Yes, EPRO-Rapid Precision offers international shipping services. We have a strong global presence and export to many countries, with significant customer bases in Europe, America, and Japan. Our logistics team ensures that your parts are delivered efficiently and securely, no matter where you are located.

How competitive are EPRO-Rapid Precision's prices?

EPRO-Rapid Precision offers highly competitive prices, often 25% to 45% lower than our Western counterparts. This cost advantage is achieved without compromising on quality or delivery times. Our strategic location, efficient production processes, and strong supplier relationships enable us to minimize costs. Additionally, our advanced manufacturing technology and skilled workforce ensure that we deliver high-quality parts at a fraction of the cost. This combination of affordability and excellence makes us a preferred partner for many global clients.

What kind of surface finishings can EPRO-Rapid provide?

At EPRO-Rapid, we offer a wide range of surface finishing options to meet various aesthetic and functional requirements. In-house, we provide cleaning and shot blasting services. Through our trusted partners, we extend our offerings to include a variety of advanced surface treatments such as: Painting, Powder coating, Chromating, Anodizing, Aluminum chrome plating, Aluminum nickel plating, These finishing techniques enhance the durability, corrosion resistance, and visual appeal of your parts, ensuring they meet your exact specifications and performance standards.

Can we need support in our work process for assembly/example with EPRO-Rapid?

Our projects include turnkey assembly services designed to meet the demands of multiple industries such as aerospace & defense, automotive, medical devices, robotics & automation and consumer products. Our experienced team makes sure that all the parts are perfectly assembled according to your condition, improving the performance and durability of final products.

Do you make your parts for immediate turn-around?

The turnaround of the part at EPRO-Rapid is unique for each part and manufacturing type and also depend on quantity, quality and complexity. In general, CNC machining takes about 5 days, 3D printing needs around 3 days and rapid tooling for moldings lasts usually 5–7days. We understand the timelines you have to meet and therefore we do our best to ensure that all deliverables adhere to the highest possible quality yet at the same time provide you with realistic and accurate project-wise timelines.

Latest Posts

Introduction In the ever-evolving world of fashion, staying ahead of...

March 26, 2025

Introduction In the ever-evolving world of fashion, personalization has become...

March 26, 2025

Introduction to Virtual Clothing Customization Imagine trying on clothes without...

March 26, 2025

Introduction to Custom Clothing In the ever-evolving world of fashion,...

March 26, 2025

Put your parts into production today

All information and uploads are secure and confidential.