Aerospace & Defense

Why choose us for Aerospace & Defense Parts Making?

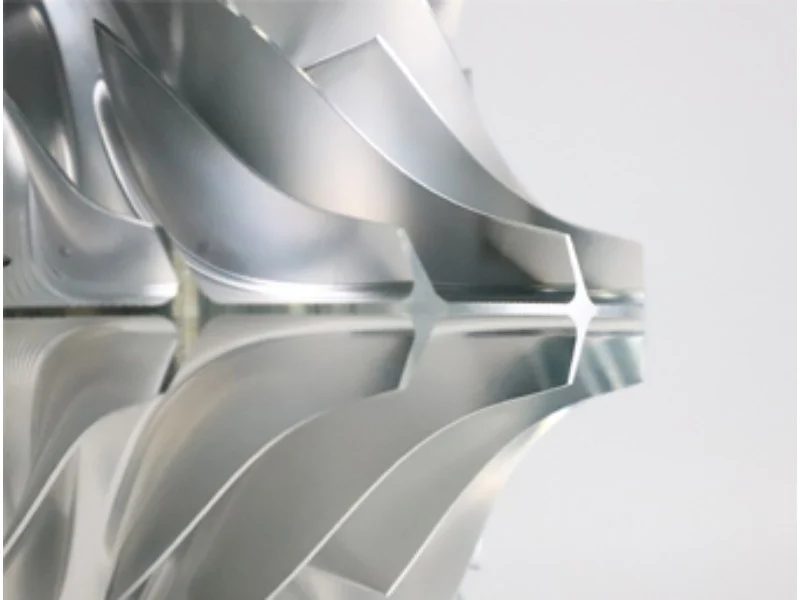

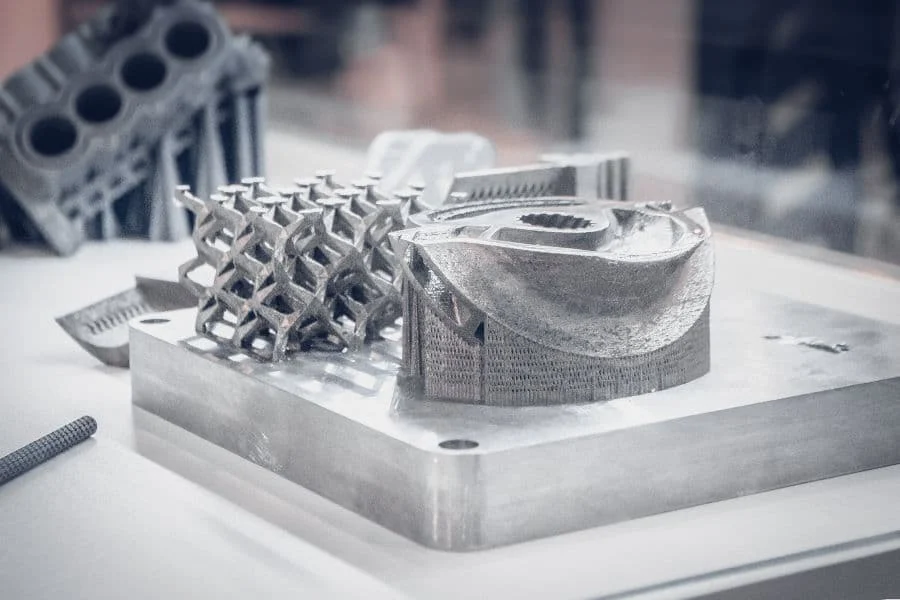

The technology of metal 3D printing

Using metal 3D printing, complex and lightweight structures can be created that were previously impossible. With this innovative process, not only are part designs lighter, but multiple metal components are eliminated in an assembly, saving money and improving efficiency.

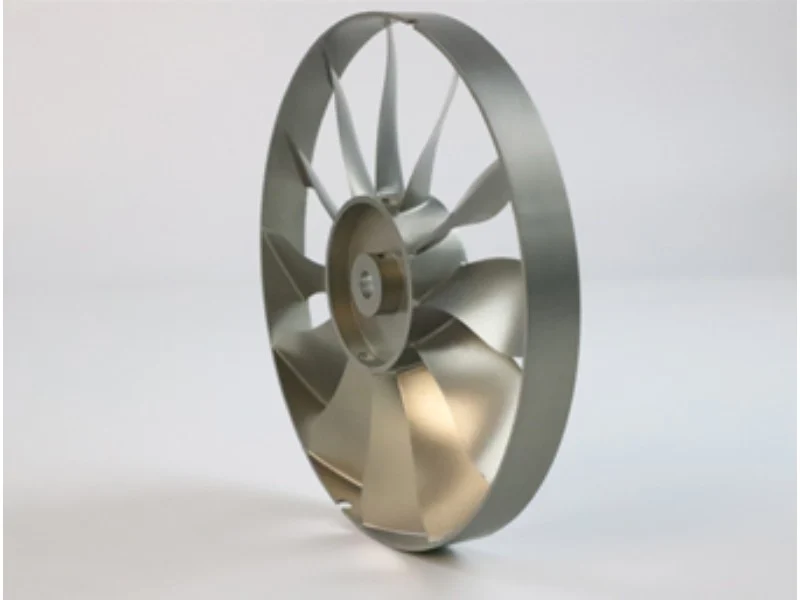

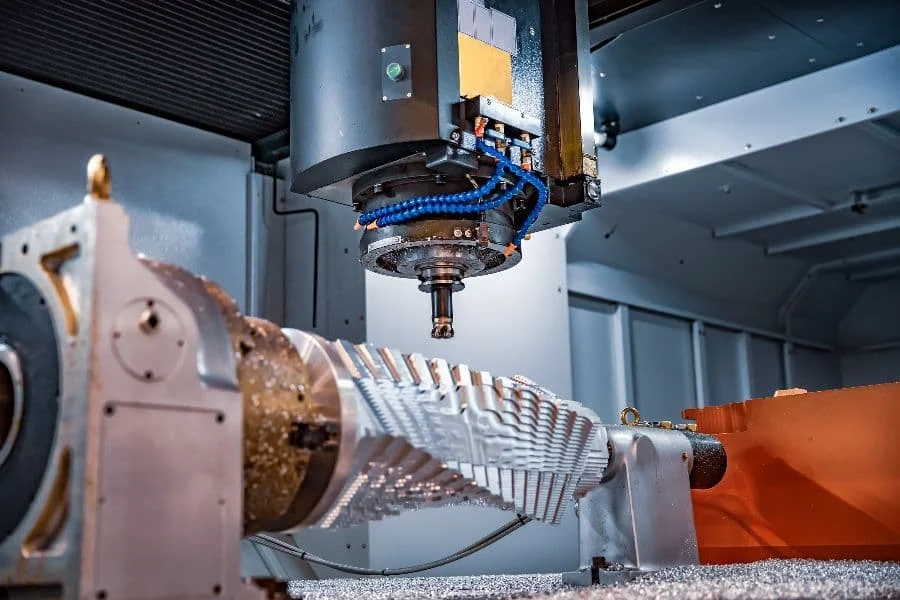

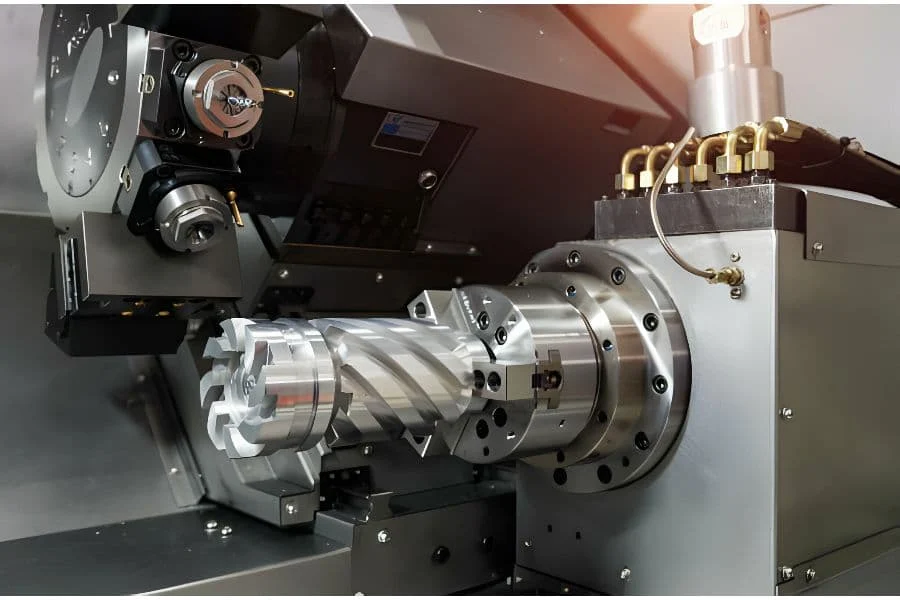

CNC machining automation

Utilize three-axis and five-axis milling as well as live tooling for increasingly complex metal and plastic components. CNC machining automates the production of intricate and personalized metal and plastic parts with minimal human involvement.

Tools,Fixtures and material used

Tools, fixtures, and other aids remain durable, production-grade. Materials like aluminum, titanium, stainless steel 17-4 PH, and Inconel can be machined with CNC machines, or 3D printed. Materials for aerospace must be durable, lightweight, and strong.

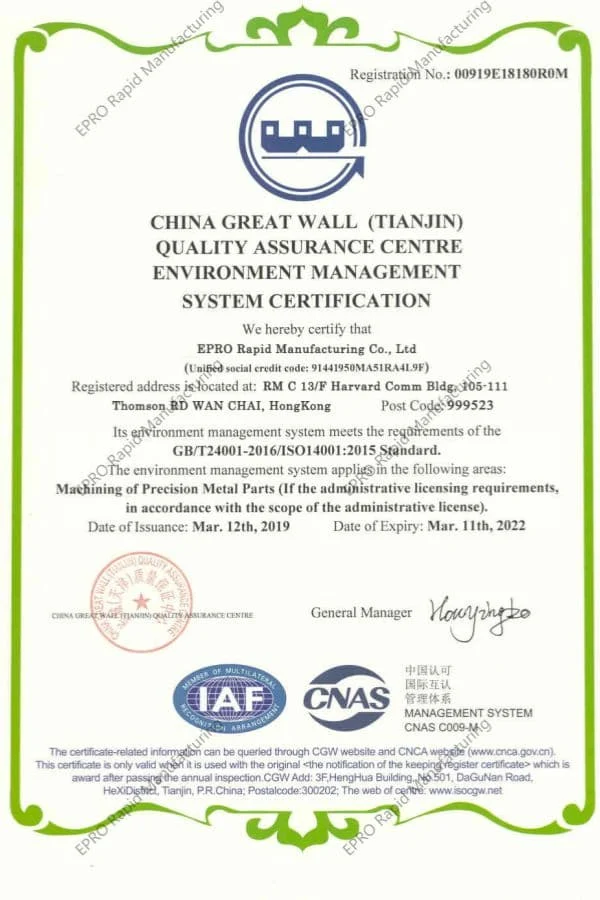

Certificates of quality and traceability

3D printing and machining processes certified to AS9100 and ISO9001. Traceability is also available for qualified projects. With our high-quality 3D printing and machining processes, you can be confident.

Aerospace and Defense Prototyping and Production Solutions

We provide solutions that ensure accurate and efficient product manufacturing, ensuring that products are safe and meet the highest quality standards. You can also get expertly engineered prototypes and production parts that are durable and perform well. Various production stages are covered by our solutions.

Prototyping

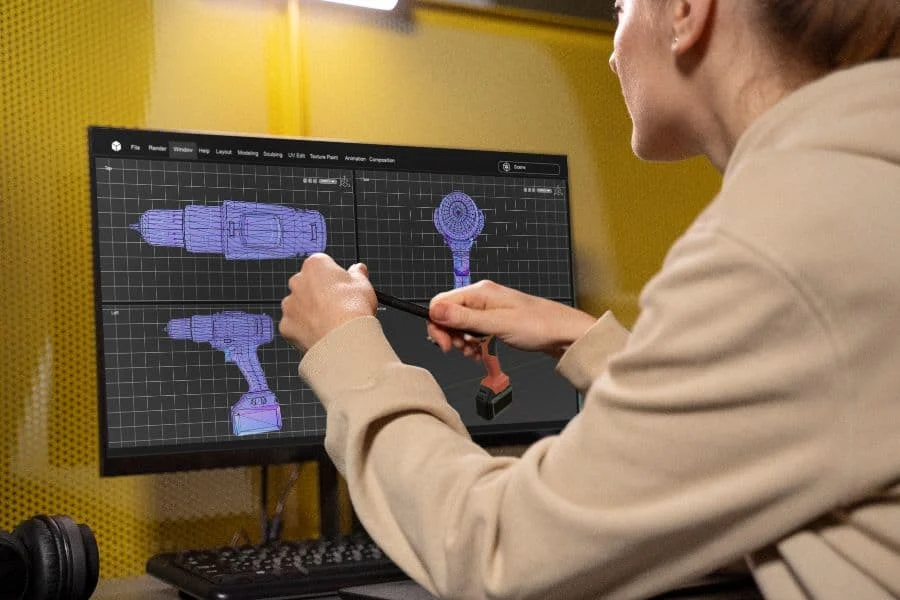

A prototype is essential for testing usability, functionality, and scalability. Also, prototypes are useful for testing design concepts and gathering feedback. Before the product is manufactured, you should test your designs, make iterations, and create prototypes.

At this stage, prototypes will be created based on your product’s requirements. Parts like the final product will be made with low-cost materials. Test prototypes for functionality, performance, and reliability. By examining specifications metrics and functional testing, we can identify potential design flaws. Our advanced technologies allow us to deliver prototypes quickly.

- Design and material iteration in a rapid manner

- Complex Geometry Prototypes

- Comparison of models with final products

Engineering Validation and Testing (EVT)

Create precise functional prototypes quickly and easily to meet all performance requirements. Before the product enters production, EVT helps identify potential issues. It ensures cost-effectiveness, quality, and reliability.

You can easily identify all design risks with our functional prototypes. It saves time and money in the long run. You can test your product’s usability with our prototypes. Lastly, our prototypes are scalable, so you can quickly customize them. It may take several iterations to meet all functional requirements.

- Manufacturing precision parts

- Support for reliable design and engineering

- Designing with optimized material properties

Design Validation and Testing (DVT)

A wide range of materials and surface finishes are available for testing part functionality, performance, and appearance. Get detailed results by using DVT’s advanced capabilities. Make sure your parts are reliable and durable by testing them with DVT.

Analyzing the final appearance and feel of the component is the purpose of this stage of production. A design error or defect is checked at this stage. Safety standards and requirements are also tested.For consumer and market testing, we create parts with end-use functionalities.

- Testing of high-quality parts for consumers and markets

- Validation of performance and appearance

- A durable and high-quality finish on the surface

Production Validation and Testing (PVT)

Make sure your design is ready for full-scale production with production-grade manufacturing capabilities and advanced quality control. PVT ensures that your product meets all quality requirements and standards. A reliable design can also be reproduced consistently. Additionally, PVT ensures that the production process is efficient and scalable.

Make sure your production goals are met during DVT. Testing the design’s performance and capability is crucial. Using the results can also help identify failures and issues before they become costly. During this stage, we will set up the supply chain and solidify manufacturing processes. The following steps can help you test and optimize your design.

- Delivery of high-quality production parts in a timely manner

- Process verification for manufacturing

- Tooling for low-volume production

- Check the functionality of production-ready parts

Mass Production

Test products before mass producing end-use components. Rapid product delivery with precise quality requirements. Automated production processes ensure accuracy and speed. Operational costs are reduced while quality standards are maintained. Utilize the latest technologies to stay ahead.

With our advanced manufacturing process and engineering expertise, we can produce your parts. Our top priority is providing high-quality parts at low prices. We test our processes thoroughly to ensure accuracy. Low costs and lead times are achieved by our professional technicians. With our engineering expertise, we guarantee the highest quality parts and service.

- Customized end-use parts of the highest quality

- Precision machined parts require tight tolerances

- Improved Surface Requirements through Secondary Operations

- Controlling and inspecting quality rigourously

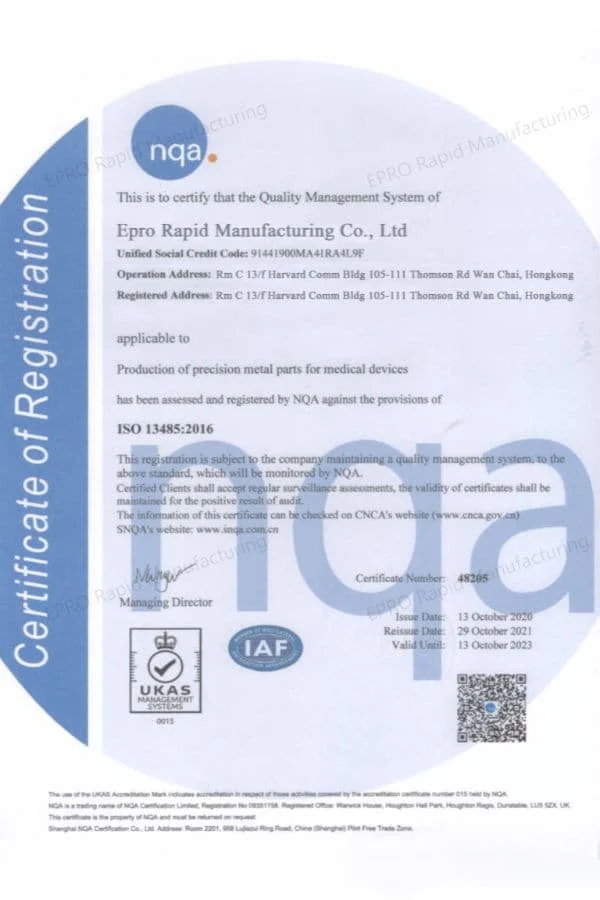

A Comprehensive Quality Documentation System

Verify quality and compliance with validation reports. Verify the accuracy and validity of the data. Check records for accuracy and completeness. Review and update documentation on a regular basis.

- ISO 9001:2015 Certificate

- ISO 13485:2016 Certificate

- ISO 14001:2015 Certification

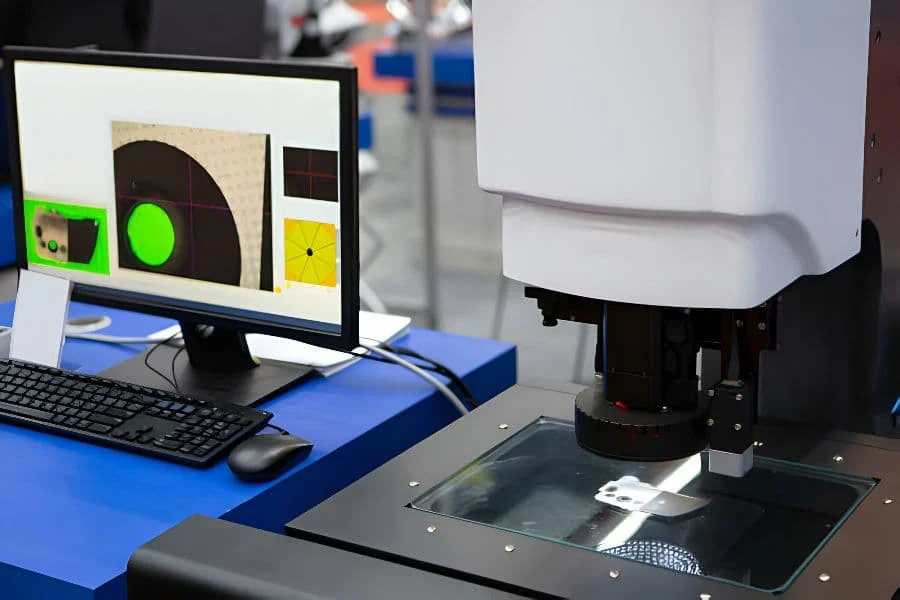

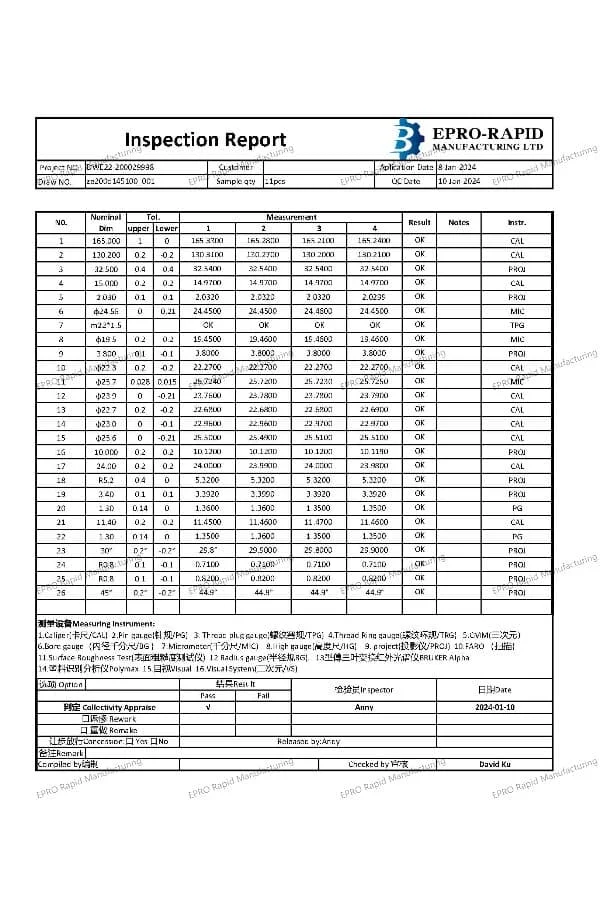

- CMM Inspection Report

- Full Dimensional Inspections

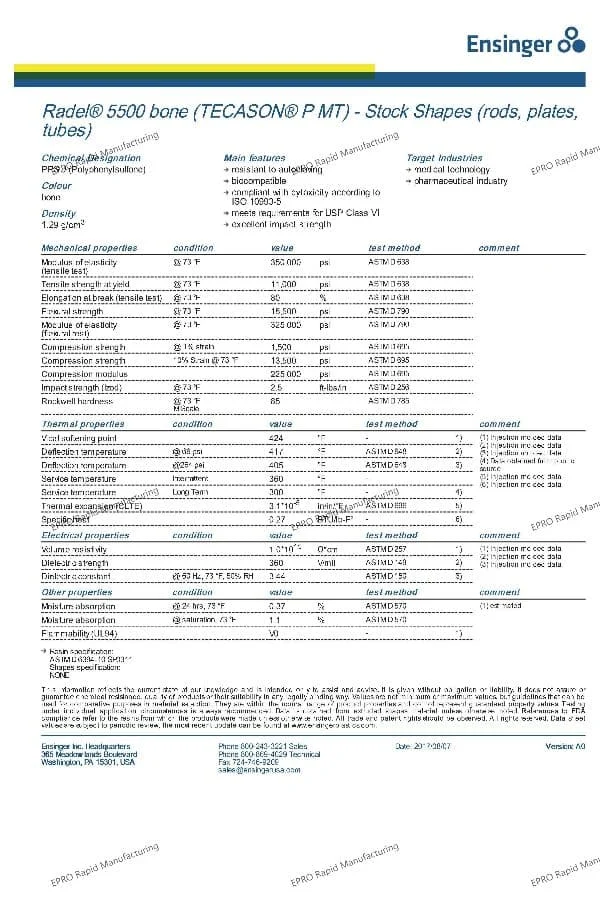

- Material Test Reports

- Material Certificates

- Certificates of Conformance

- First Article Inspections

Inspection Equipment for ensure the high-quality machined parts

For these inspections to be effective, the right equipment must be used. In order to ensure machined parts meet the specifications, precision measuring tools such as calipers, micrometers, and coordinate measuring machines (CMMs) can be used. We are able to ensure accuracy of your order by using a variety of high-quality imported and domestic equipment.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

Applications in the aerospace and defense industries

We can accelerate aerospace and defense component production for a wide range of applications. Aircraft and defense industries demand rigorous standards from our products and services. Injection molding, 3D printing, and CNC machining are our precision manufacturing solutions. The following are some of our common aerospace and defense applications:

- Seats

- Engines

- Fuselages

- Turbines

- Fastening Items such as Screws

- Tire Parts

- Brakes

- Electrical Parts

- Radar Systems

- Air Conditioning Systems

- Vacuum Pumps

- Fuel Pumps

- Lighting System

- Gears

- Wing Support

- Night Vision Device

- Transmission Components

- Dashboard

- Helmets

- Unmanned Aerial Vehicle

- Teaching Aids

- Tank Model

- Aircraft interiors

- Spacecraft and satellite components

- Telecommunications components

- Optical system components

- Military rifle components

- Military vehicle components

- Military UAV and drone components

- High-performance tools and fixtures

Who are the clients we serve?

- Suppliers of aircraft OEMs

- Suppliers at Tier 1

- Contractors in the defense industry

- Operators and manufacturers of satellites

- Maintenance, repair, and overhaul companies for aircraft

- Operators of space launches

- Providing drone/UAV services to commercial, industrial, and military clients

- Agencies of the federal government

Aerospace and Defense Manufacturing Capabilities

EPRO offers wide range of manufacturing processes for Aerospace and Defense prototypes and production parts.

CNC Machining

Precision-crafted components for aerospace and defense applications, ensuring optimal performance.

Injection Molding

Streamlined production of intricate parts, meeting the stringent demands of aviation and defense.

3D Printing

Rapid prototyping and customization, providing innovative solutions for aerospace and defense needs.

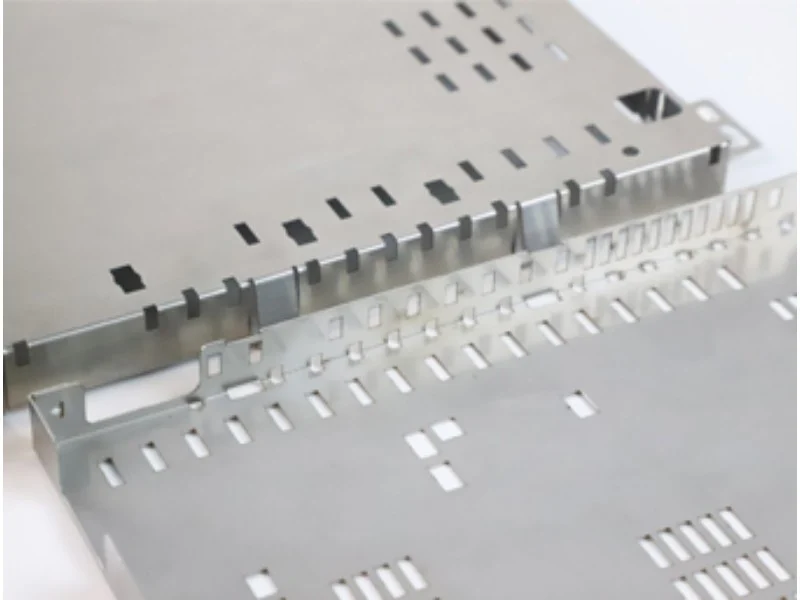

Sheet Metal Fabrication

Versatile metal solutions catering to the unique requirements of the aerospace and defense industry.

Materials used in the aerospace and defense industries

Material options are available with all of our manufacturing processes. Metals, polymers, alloys, composites, and plastics are just some of the materials we work with. In addition, we specialize in high-performance materials. Our reliable, cost-effective solutions can meet all your manufacturing needs. These are some common aerospace and defense options.

Materials used in the aerospace and defense industries

| Image | Material | Best Tech. | Benifits | Sample Parts |

|

Steel | CNC machining, rapid tooling | Strong, corrosion-resistant, range of grades | Brake components, engine components |

|

Aluminum | CNC machining, rapid tooling, sheet metal | Machinable, strong, range of grades | Cylinder heads, manifolds, Ductwork, housings, bus ducts |

|

Titanium | CNC machining, SLM 3D printing | Lightweight, temperature-resistant | Engine valves, axle shafts, pipes, nuclear waste storage, pumps, turbines |

|

PA(Nylon) | CNC machining, SLS 3D printing, injection molding | Strong, smooth surface finish | Peripheral engine parts, covers and housings |

|

PMMA | CNC machining, injection molding | Transparent, shatter-resistant | Lighting components |

|

|

Silicone | Liquid silicone injection molding | Durable, flexible, biocompatible, inert | Seals, cover assemblies, Fluid management devices, respiratory devices |

Finishes applicable to the aerospace and defense industries

Surface finishes are available in a wide range from us.Our finishing options include electroplating, powder coating, and anodizing. We also offer custom finishing for aerospace and defense parts in addition to chemical etching, laser engraving, and other specialty finishes.

| Image | Item | Applicable To | Feature | Color | Thickness |

|

As machined | Metals & Plastics | Tool marks visible | N/A | N/A |

|

Polishing | Metals & Plastics | Brushed & gloss mirror surface | N/A | 0.02-0.05mm removed |

|

Sand, Bead Blasted | Metals & Plastics | matt or satin surface | N/A | N/A |

|

Painting | Metals & Plastics | Matt, gloss, texture | colors can be matched as needed | 0.05mm to 0.1mm |

|

Powder coating | Metals | Matt, gloss, texture | colors can be matched as needed | 0.05mm to 0.15mm |

|

Anodization | Aluminum | Tool marks visible, Smooth, Matt & Gloss | colors can be matched as needed | 0.002mm to 0.04mm |

|

E-Coating | Metals | Matt & Gloss | Black | 0.015mm to 0.035mm |

|

Nickel Plating | Metals | Gloss | Silver | 0.004mm to 0.05mm |

|

Chromed Plating | Metals & Plastics | Satin & Gloss | Silver | 0.001mm to 0.3mm |

|

Zinc Plating | Metals | Gloss | Silver & Black | 0.005mm to 0.2mm |

|

Chromate Conversion Coating | Aluminum | Tool marks visible, Smooth and Matt | Clear/ slight yellow tint | 0.25-1 um |

Put your parts into production today

All information and uploads are secure and confidential.

Tour Our 5 Axis Machine Shop

Check out our incredible line of well-functioning 5-axis machining centers ranging from the best 5-axis horizontal machining center to top-notch vertical machining centers. These are ideal facilities for manufacturing components for various industries. We combine advanced technologies with skilled technicians to deliver results to suit your needs perfectly.

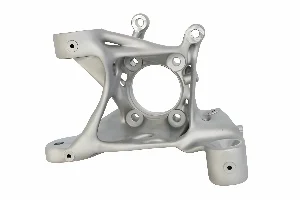

Gallery Of Aerospace and Defense Parts

Check out our display of Sheet Metal Parts. At EPRO, you can confidently get the best Sheet Metal parts!