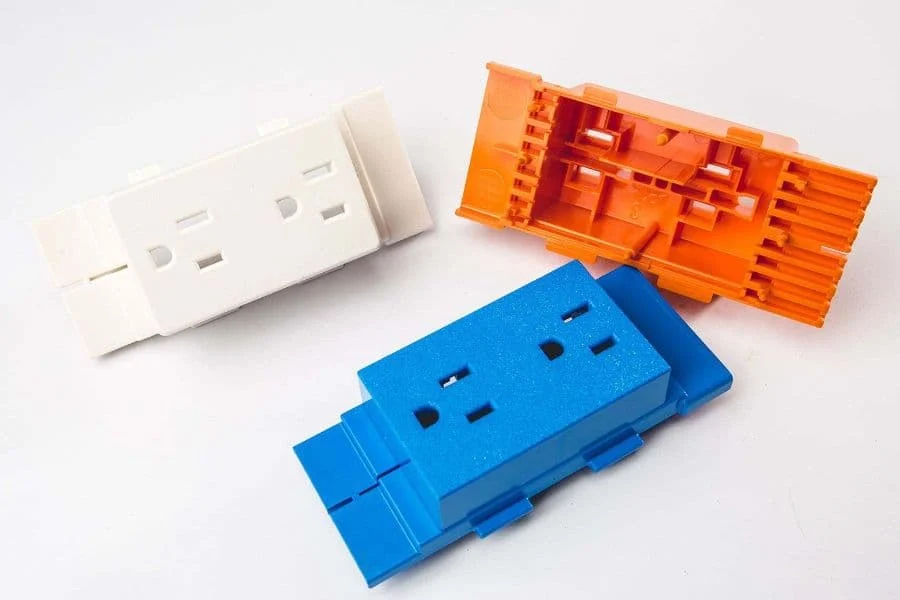

Custom Injection Molding Services

Injection molding: What Is It?

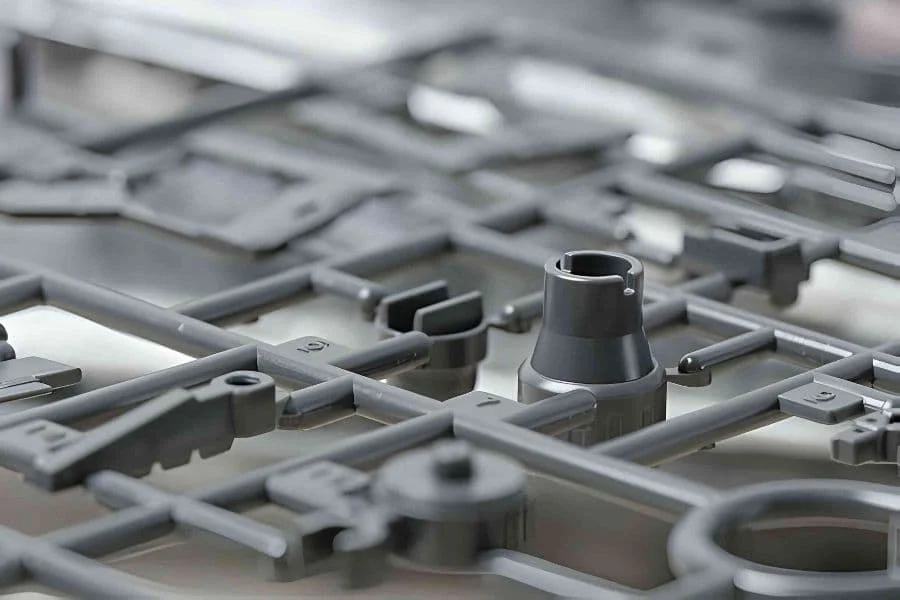

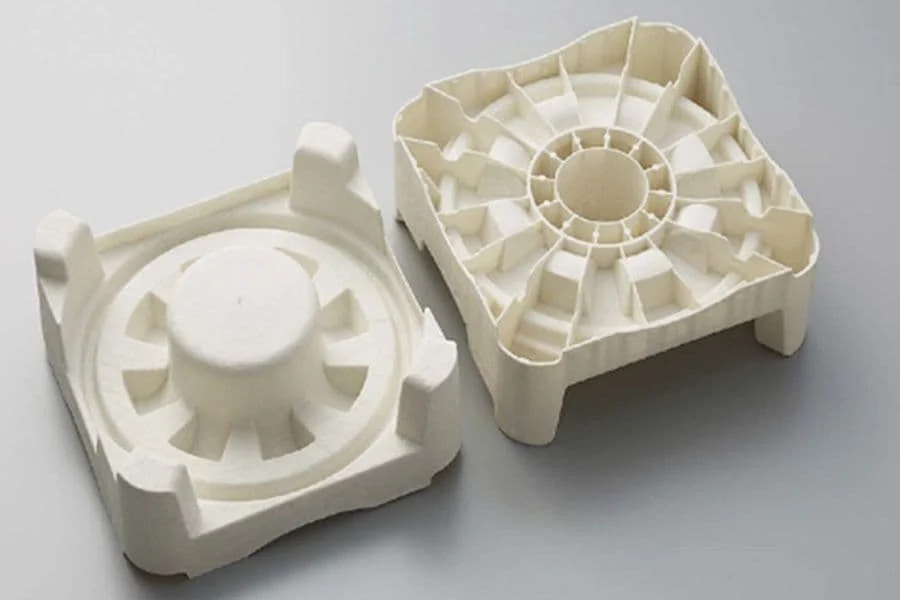

Plastic parts can be more cost-effectively made at scale using injection molding. Plastic molten is injected into a mold tool, then the solidified part is ejected. Mold tool costs are amortized hundreds or thousands of times, lowering unit costs to a few dollars. Injection molding makes plastic parts mass-producible. Because injection molding uses the same mold tool for all parts, it provides consistent quality across the board. Furthermore, injection molding produces complex parts with tight tolerances, making it the perfect choice for many industrial applications. Injection molding provides more materials, colors, cosmetics, polishes, and surface textures than CNC machining or even 3D printing. This makes it ideal for mass production of plastic components.

Injection molding: why choose EPRO?

Made in high-quality facilities

We are ISO 9001:2015 certified at IJM Facilities. The IJM Facilities meet the highest quality standards, and their facilities are regularly inspected and audited to ensure compliance.

Your press needs the right tooling capabilities

Tools can be designed with fully automated slides, lifters, and bases. There are different press tonnages to fit your part size. Automated tool bases provide stability for automated tool systems. We can adjust our press tonnages to your part size. To fit your needs, we customize our tooling.

Uniquely design the part

We specialize in custom finishes. We specialize in injection molding custom finishes, ensuring each part looks unique. Whether you need textured surfaces or vibrant colors, we have what you need.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

Thermoplastic Materials

Over 100 thermoplastic and thermoset materials are available from us. We also offer an overview of resin substitutes for ABS, PC, PP, and other commonly molded plastics.The information we provide our customers helps them make the best choice. Our technical expertise also helps our customers select the right material for their needs. Lastly, we offer competitive prices on all our materials.

- ABS

- ABS/PC

- Acetal

- Acetal Homopolymer/Delrin

- ETPU

- HDPE

- LCP

- LDPE

- LLDPE

- Nylon

- PBT

- PC/PBT

- PEEK

- PEI

- PET

- PETG

- Polycarbonate

- Polypropylene

- PPA

- PPE/PS

- PS

- PSU

- TPU

- PMMA (Acrylic, Plexiglas)

Thermoplastics Materials view

ABS

PC

Polypropylene

PMMA

POM

Finishes available for surfaces

Depending on the requested finish, draft angles will vary. In addition to Mold-Tech finishes, industry standards are also available. In addition to matte and high gloss finishes, satin is also available. Custom finishes can also be provided upon request. Depending on your requirements, we can customize our finishes.

| Finish | Description |

| Standard | non-cosmetic, finish per EPRO's discretion |

| Smooth | low-cosmetic, most tool marks removed |

| VDI Texture | non-cosmetic, EDM permissible |

| SPI-C1 | 600 grit stone, 10-12 Ra |

| SPI-D1 | SPI-C1 + light bead blast |

| SPI-D2 | SPI-C1 + medium bead blast |

| SPI-B1 | 600 grit paper, 2-3 Ra |

| SPI-A2 | grade #2 diamond buff, 1-2 Ra |

Custom molded parts quality inspections and finishing options

Depending on your application’s requirements, you can choose from the following when requesting an injection molding quote.

On-demand manufacturing inspections are available

- Manufacturability Feedback Design (DFM)

- Process development report for scientific molding

- Inspection and monitoring of machines in-process with a CMM

- Inspection of first articles (FAI) and the report on process capability prepared by GD&T

Our Post-Processing:

Threaded Inserts

Laser Engraving

Your parts can be engraved with part numbers, logos, and more.

Component Assembly

EPRO can assemble and label injection molded parts. With your salesperson, discuss your needs.

Surface Finishes for Plastic Injection Molding

Plastic injection molded parts can be improved with superior surface finishes.We offer professional, high-quality surface finishes for plastic parts. A wide variety of surface treatments are available from EPRO to increase the aesthetics of your products. Furthermore, these efficient secondary operations improve prototypes and production parts’ mechanical properties.Get started today by contacting us.

Description of Semi-glossy

B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture.

Description of Glossy

A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts.

Description of Matte

C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture.

Description of Textured

D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish.

Advantages of EPRO'S Injection Molding

Tooling and DFM expertise in-house

Each project is optimized with our internal resources. Our DFM experts optimize tool design before production begins. We can ensure top quality and short lead times this way.

Complex Process Excellence

We produce consistently high-quality products through insert-molding and over-molding. Complex processes are our expertise. Quality control protocols ensure customer satisfaction. Products and services of high quality are our priority.

Scalable Manufacturing Setup

Our flexible workstations and production lines enable us to handle plastic assemblies of varying sizes. Automation ensures speed and accuracy, while skilled technicians ensure quality. We can customize assembly processes with flexible workstations.

Customized and Comprehensive Solutions

We also offer production and assembly services. Material, fabrication, and assembly solutions tailored to our clients. We guarantee quality and reliability.

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

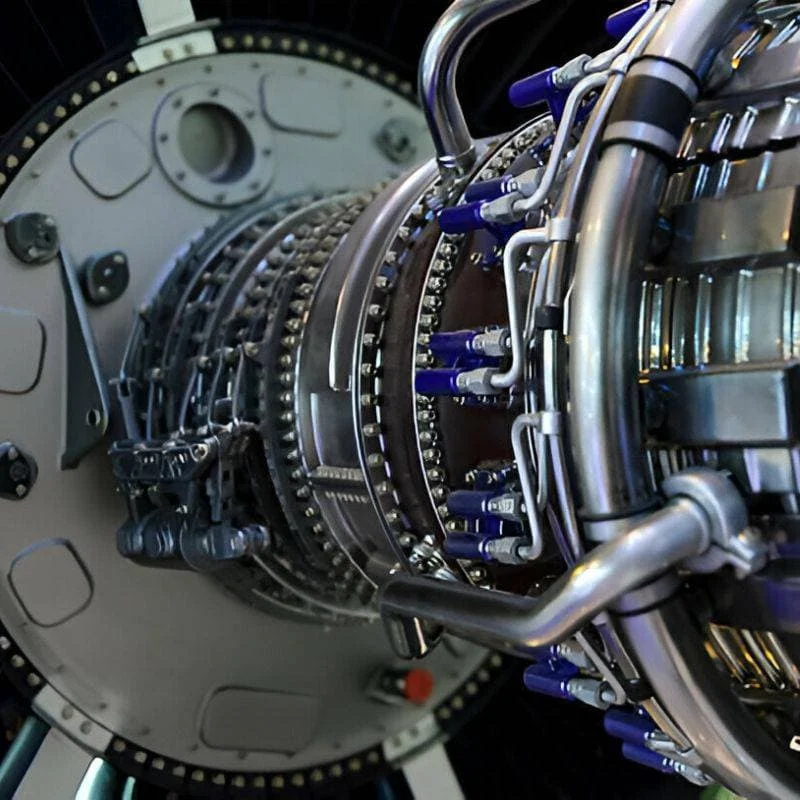

Plastic injection molding applications

The plastic injection molding process has numerous applications across a wide range of industries. With its precision and efficiency, it is indispensable for automotive components, medical devices, consumer electronics, and more. In diverse sectors, this technology delivers high-quality and customized plastic products for a variety of industrial uses.

Plastic injection molding tips

Here are some expert tips for elevating your plastic injection molding projects. To begin, choose the right resin based on factors such as strength, durability, and temperature resistance. Minimize undercuts and incorporate uniform wall thicknesses for optimal moldability. Work closely with our experienced team to optimize tooling design and injection parameters.

We invite you to tour our injection molding workshop

Visit our cutting-edge plastic injection molding workshop and see how manufacturing will evolve in the future. We transform raw materials into precision-engineered plastic components through seamless integration of advanced machinery and skilled craftsmanship. The mold design and product finishing are meticulously executed to guarantee high quality. Explore our innovation and excellence in plastic injection molding with this immersive tour.

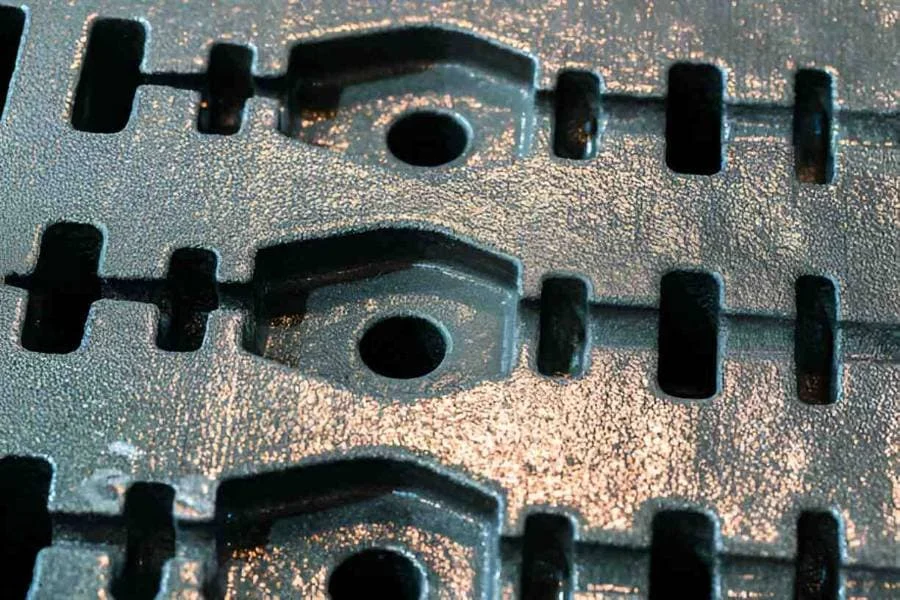

Gallery Of Plastic Injection Molding Parts

Check out our display of Plastic Injection Molding Parts. At EPRO, you can confidently get the best Plastic Injection Molding parts!