Medical Device Prototyping and Production

What are the advantages of choosing EPRO for the manufacture of medical parts?

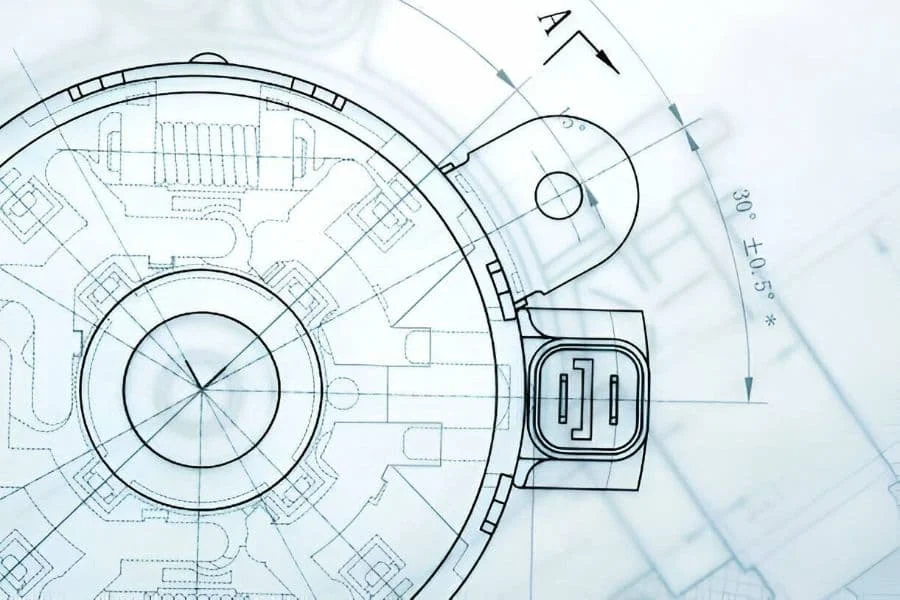

Analyzing designs interactively

Save time and money by making critical design adjustments based on design for manufacturability (DFM) feedback. DFM feedback is especially important for medical parts manufacturing, since it helps ensure that parts are manufactured efficiently and meet quality standards.

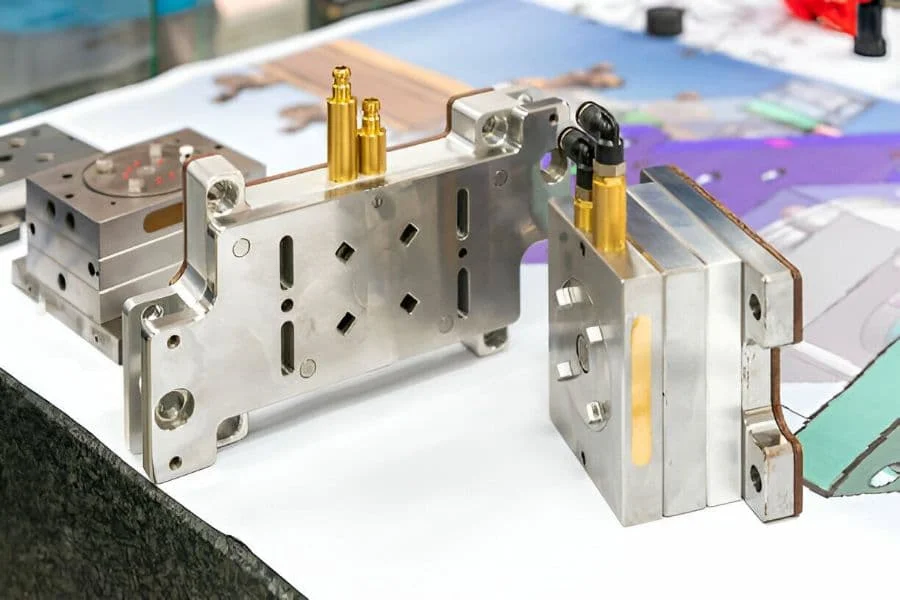

Production Tooling for Bridges

Utilize affordable bridge tooling to validate design and market before investing in more expensive tools. For medical parts making, affordable bridge tooling allows testing and validation of designs before committing to expensive production tooling, allowing for early adjustments and improvements.

Technologically agnostic

With our manufacturing technologies, we can pair your parts with the right process and equipment no matter what your project requirements are. The precision and accuracy of the manufacturing process ensures that medical parts meet the strict quality standards of the industry.

Materials used in medicine

We offer high-temperature plastics, medical-grade silicone rubber, 3D-printed microfluidics, and hundreds of other plastics, metals, and elastomerics. Materials like these are commonly used in the manufacture of medical parts because they are biocompatible, durable, and sterilizable. Medical equipment and devices are safe and effective.

Solutions for prototyping and production in the medical industry

Providing reliable new product development solutions for the medical industry. We offer unique prototyping and production solutions that meet the unique requirements of the medical industry, ensuring that new products can be developed and manufactured accurately. Get expertly engineered custom prototypes and production parts with outstanding performance and durability. Developing and manufacturing reliable medical products is easy with us. We offer solutions at various stages of the manufacturing process to meet your needs.

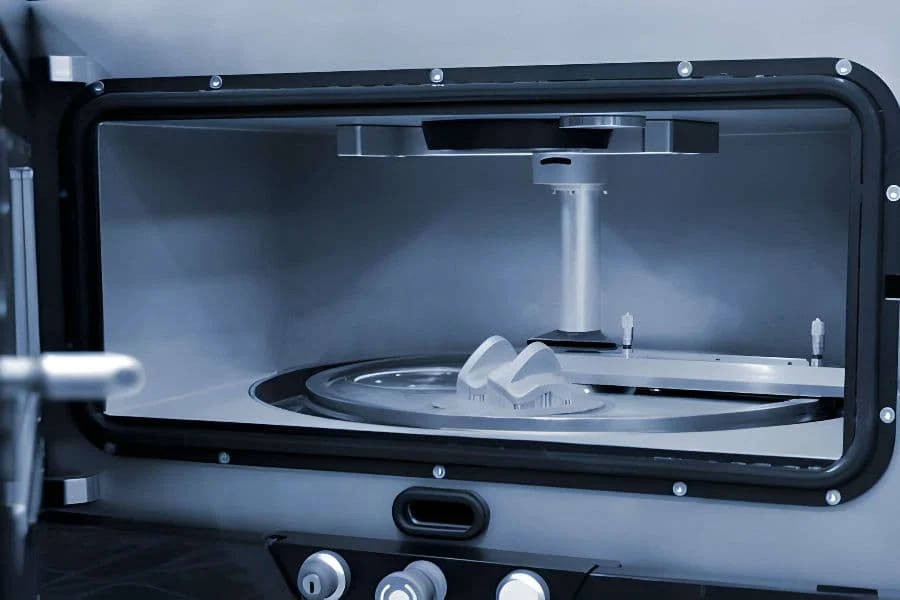

Rapid Prototyping

Print prototypes or organ scans in 3D to preview before medical procedures or produce prototypes in production-grade materials for functional and regulatory testing. We provide precision and accuracy in producing vital medical components, whether you need prototypes for functional and regulatory testing or want to preview medical procedures through 3D printing.

Produced in low volumes

You can streamline your supply chain before and after products are launched by getting low-volume production parts in as little as one day. A steady supply of medical parts is essential for healthcare providers and patients in need since low-volume production allows for quick, efficient production of essential medical devices and components.

Mass Production

From Prototype to Volume Production of medical parts, with advance manufacturing capabilities. We’re dedicated to ensuring your products achieve high quality and performance requirements at lower cost and faster delivery times.

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

Medicinal parts applications

As healthcare system procurement processes evolve, we have a deep understanding of the forces that shape your business. To stay competitive in a rapidly changing landscape and navigate complex regulations and compliance requirements effectively, it is essential for the medical industry to understand these forces. Our expertise can help you stay ahead of the curve and remain a leader in the medical field.

If you’re looking for a contract manufacturer that offers deep engineering expertise in your industry, speed and adaptability, EPRO can help you accelerate your new product innovation, prototyping and production programs.

- Prototypes

- Anatomical models

- Replacement parts

- Surgical instruments

- MRI and X-Ray components

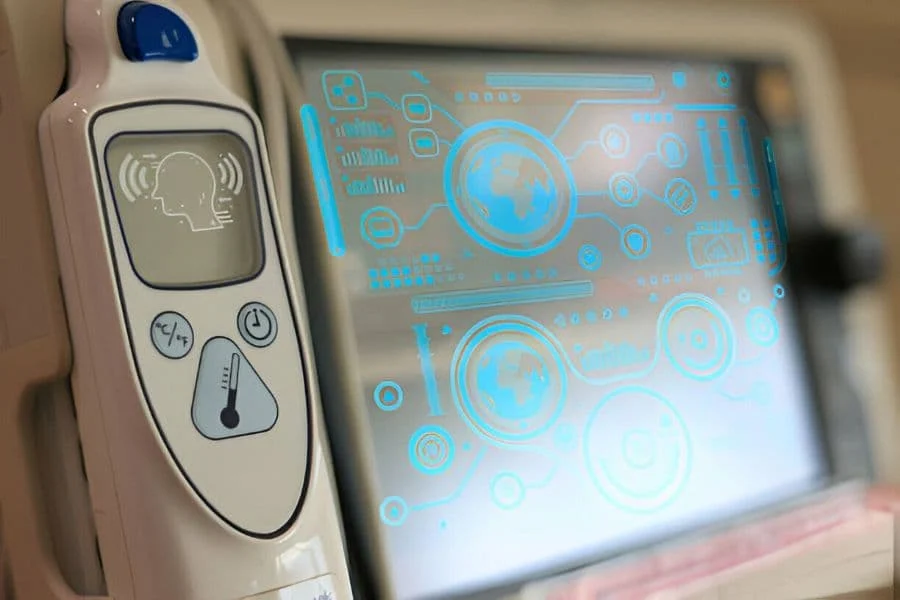

- Monitoring equipment components

- Tables and panels

- Medical carts

- Physiotherapy apparatuses

- Electronic equipment components

- Prostheses

- Medical delivery systems

- Biotechnology components

- Respiratory devices

- Diagnosis equipment

- Ultrasonic equipment

- Care equipment

- Enclosures and housings

- Implantable prototypes

- Prosthetic components

- Microfluidics

- Wearables

- Cartridges

- Handheld devices

- Surgical instruments

- Prosthetic devices

- Medical testing devices

- Medical delivery systems

- Ventilators

- UV sanitation components

- FDA Class 1 and 2 devices

- Surgical robotics

- UV sanitation robots

- Personal wellness devices

- Non-invasive medical components

- Medical delivery systems

- Medical testing devices

What is the scope of our services?

- Companies that manufacture medical devices

- The healthcare industry

- Biological sciences

- Companies involved in biotechnology

- Companies that manufacture pharmaceuticals

- Suppliers of diagnostic equipment

- Instrument manufacturers for surgery and medicine

- Manufacturers and suppliers of surgical appliances

- A hospital’s operator

Medical Manufacturing Capabilities

EPRO offers wide range of manufacturing processes for Medical prototypes and production parts.

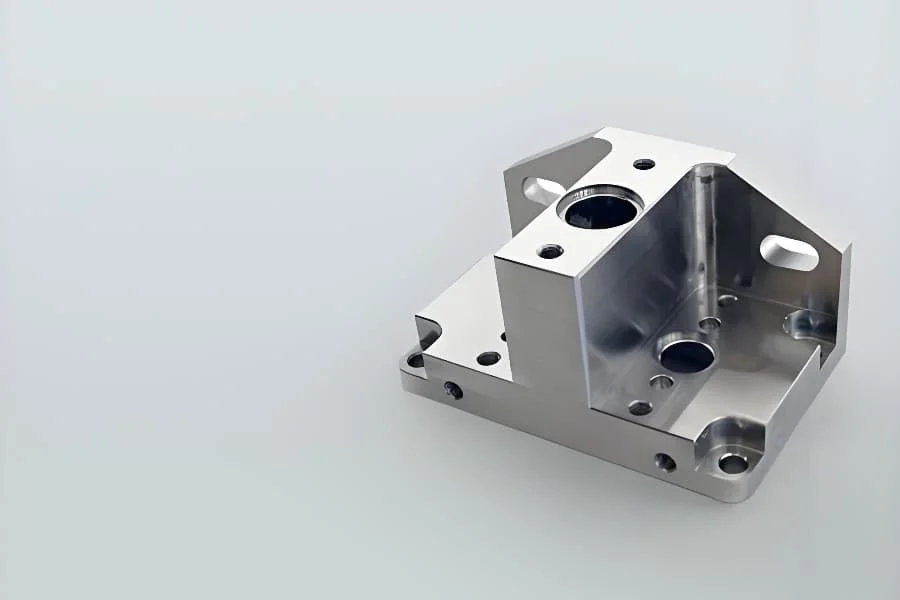

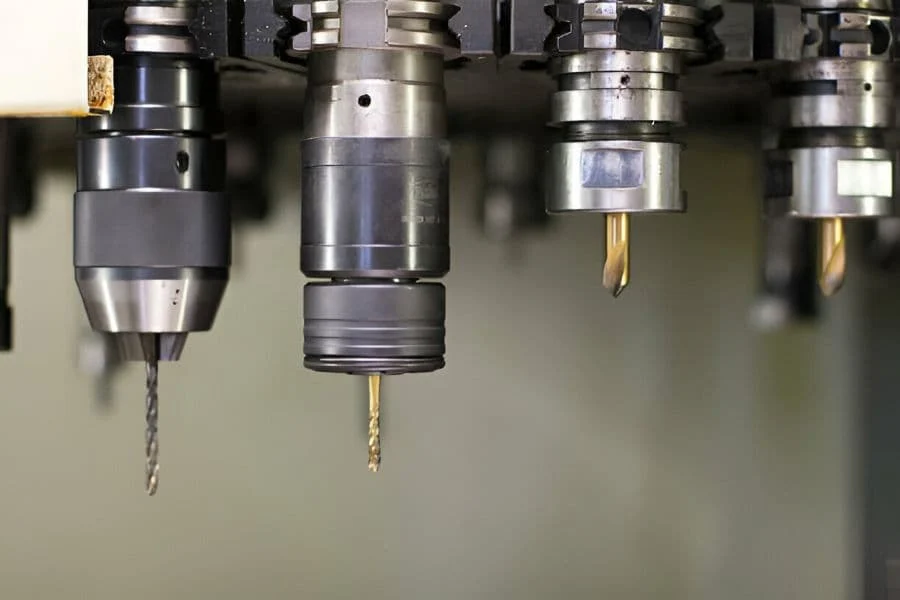

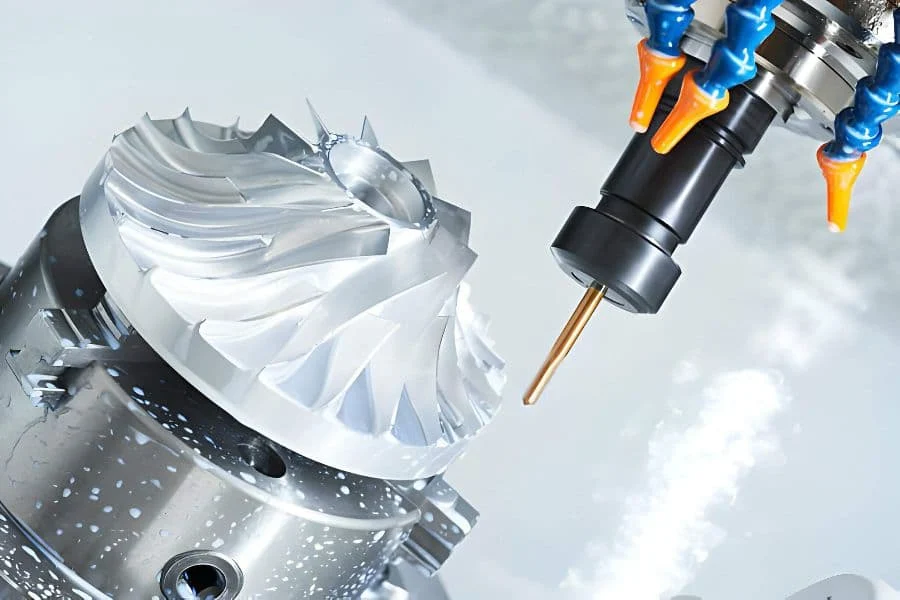

CNC Machining

Creating intricate medical device components with precision and accuracy.

Injection Molding

Manufacturing high-quality plastic components for medical equipment and devices.

3D Printing

Prototyping customized medical implants and prosthetics for personalized patient care.

liquid silicone rubber molding

Producing flexible and biocompatible medical devices and seals for healthcare applications.

Materials for medical manufacturing

The materials we use in all our manufacturing processes offer a wide range of possibilities. Materials we use in the medical industry are specially designed and tested to ensure their safety, durability, and compatibility with various medical devices and equipment. Consequently, our products are reliable, safe, and of the highest quality. Here are a few of the most popular material choices for medical parts projects.

| Image | Material | Best Tech | Benifits | Sample Parts |

|

Stainless Steel | CNC machining, sheet metal | Strong, corrosion-resistant, sterilizable, range of grades | Surgical instruments, Heat exchangers, pumps, tubing |

|

Titanium | CNC machining, SLM 3D printing | Lightweight, temperature-resistant | Engine valves, axle shafts, pipes, nuclear waste storage, pumps, turbines |

|

PC | CNC machining, injection molding | Impact-resistant, sterilizable, transparent | Drug delivery devices, clear fluid management devices |

|

PEEK | CNC machining, injection molding | Strong, sterilizable, chemically resistant, temperature-resistant | Implants, turbine blade supports, solar panels, housings |

|

|

Silicone | Liquid silicone injection molding | Durable, flexible, biocompatible, inert | Seals, cover assemblies, Fluid management devices, respiratory devices |

Finishes suitable for the medical industry

Surface finishes at high levels are available from us in a wide variety. For the medical industry, antimicrobial coatings can help prevent the growth of bacteria, as well as smooth, easy-to-clean surfaces that minimize contamination risks. Below are some common finishing options. We would be happy to assist you with any additional requirements you may have. For custom parts in the medical industry, there are more finish options.

| Image | Item | Applicable To | Feature | Color | Thickness |

|

As machined | Metals & Plastics | Tool marks visible | N/A | N/A |

|

Polishing | Metals & Plastics | Brushed & gloss mirror surface | N/A | 0.02-0.05mm removed |

|

Sand, Bead Blasted | Metals & Plastics | matt or satin surface | N/A | N/A |

|

Painting | Metals & Plastics | Matt, gloss, texture | colors can be matched as needed | 0.05mm to 0.1mm |

|

Powder coating | Metals | Matt, gloss, texture | colors can be matched as needed | 0.05mm to 0.15mm |

|

Anodization | Aluminum | Tool marks visible, Smooth, Matt & Gloss | colors can be matched as needed | 0.002mm to 0.04mm |

|

E-Coating | Metals | Matt & Gloss | Black | 0.015mm to 0.035mm |

|

Nickel Plating | Metals | Gloss | Silver | 0.004mm to 0.05mm |

|

Chromed Plating | Metals & Plastics | Satin & Gloss | Silver | 0.001mm to 0.3mm |

|

Zinc Plating | Metals | Gloss | Silver & Black | 0.005mm to 0.2mm |

|

Chromate Conversion Coating | Aluminum | Tool marks visible, Smooth and Matt | Clear/ slight yellow tint | 0.25-1 um |

Put your parts into production today

All information and uploads are secure and confidential.

Tour Our 5 Axis Machine Shop

Check out our incredible line of well-functioning 5-axis machining centers ranging from the best 5-axis horizontal machining center to top-notch vertical machining centers. These are ideal facilities for manufacturing components for various industries. We combine advanced technologies with skilled technicians to deliver results to suit your needs perfectly.

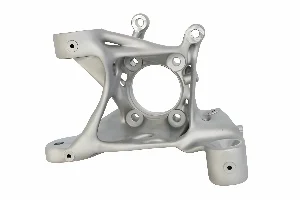

Gallery Of Medical Parts

Check out our display of Sheet Metal Parts. At EPRO, you can confidently get the best Sheet Metal parts!