Consumer Products

Why choose us for Consumer Products Parts Making?

ISO certified

- EPRO is an ISO9001-2015 certified manufacturer that can guarantee top quality parts in an industry that demands rigorous consistency and quality control.

Range of services

- Equal parts machine shop and digital manufacturing specialist, we offer a range of manufacturing technologies and services, from CNC machining to 3D printing.

Short lead time

- Our extensive facilities and partner network allow us to fulfill orders quickly, no matter the quantity or complexity.

Skilled and experienced

- We have been manufacturing consumer products parts for over a decade and our skilled engineers know how to get the best outcomes from your

Easy quotation system

- Our engineers will review your designs immediately to provide a fast and accurate quotation for the project.

Prototyping and Production Solutions for Consumer Products Industry

Reliable solutions for new product development in the aerospace and Defense industry. Get expertly engineered custom prototypes and production parts with outstanding performance and durability. Our solutions span various production stages to meet your manufacturing goals.

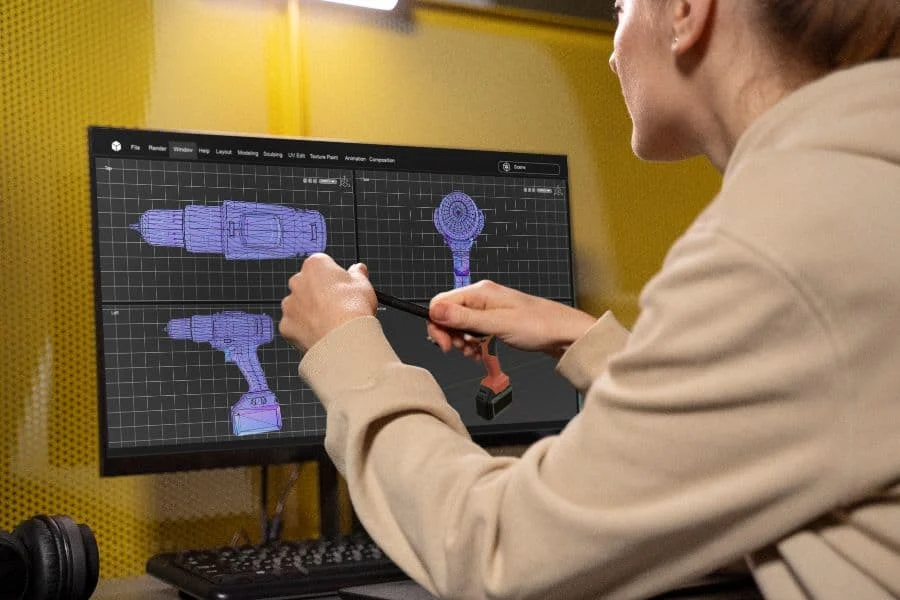

Prototyping

A prototype is essential for testing usability, functionality, and scalability. Also, prototypes are useful for testing design concepts and gathering feedback. Before the product is manufactured, you should test your designs, make iterations, and create prototypes.

At this stage, prototypes will be created based on your product’s requirements. Parts like the final product will be made with low-cost materials. Test prototypes for functionality, performance, and reliability. By examining specifications metrics and functional testing, we can identify potential design flaws. Our advanced technologies allow us to deliver prototypes quickly.

- Design and material iteration in a rapid manner

- Complex Geometry Prototypes

- Comparison of models with final products

Engineering Validation and Testing (EVT)

Create precise functional prototypes quickly and easily to meet all performance requirements. Before the product enters production, EVT helps identify potential issues. It ensures cost-effectiveness, quality, and reliability.

You can easily identify all design risks with our functional prototypes. It saves time and money in the long run. You can test your product’s usability with our prototypes. Lastly, our prototypes are scalable, so you can quickly customize them. It may take several iterations to meet all functional requirements.

- Manufacturing precision parts

- Support for reliable design and engineering

- Designing with optimized material properties

Design Validation and Testing (DVT)

A wide range of materials and surface finishes are available for testing part functionality, performance, and appearance. Get detailed results by using DVT’s advanced capabilities. Make sure your parts are reliable and durable by testing them with DVT.

Analyzing the final appearance and feel of the component is the purpose of this stage of production. A design error or defect is checked at this stage. Safety standards and requirements are also tested.For consumer and market testing, we create parts with end-use functionalities.

- Testing of high-quality parts for consumers and markets

- Validation of performance and appearance

- A durable and high-quality finish on the surface

Production Validation and Testing (PVT)

Make sure your design is ready for full-scale production with production-grade manufacturing capabilities and advanced quality control. PVT ensures that your product meets all quality requirements and standards. A reliable design can also be reproduced consistently. Additionally, PVT ensures that the production process is efficient and scalable.

Make sure your production goals are met during DVT. Testing the design’s performance and capability is crucial. Using the results can also help identify failures and issues before they become costly. During this stage, we will set up the supply chain and solidify manufacturing processes. The following steps can help you test and optimize your design.

- Delivery of high-quality production parts in a timely manner

- Process verification for manufacturing

- Tooling for low-volume production

- Check the functionality of production-ready parts

Mass Production

Test products before mass producing end-use components. Rapid product delivery with precise quality requirements. Automated production processes ensure accuracy and speed. Operational costs are reduced while quality standards are maintained. Utilize the latest technologies to stay ahead.

With our advanced manufacturing process and engineering expertise, we can produce your parts. Our top priority is providing high-quality parts at low prices. We test our processes thoroughly to ensure accuracy. Low costs and lead times are achieved by our professional technicians. With our engineering expertise, we guarantee the highest quality parts and service.

- Customized end-use parts of the highest quality

- Precision machined parts require tight tolerances

- Improved Surface Requirements through Secondary Operations

- Controlling and inspecting quality rigourously

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

Consumer Products Applications

Our manufacturing capabilities help accelerate the production of a wide range of aerospace and defense components for unique applications. Here are some of the common aerospace and defense applications:

- Personal products

- Electronic devices housings

- Wearable devices

- Cookware products

- Athletics and sporting equipment

- Accessory components

- Virtual reality products

- Buttons

- Handles

- Knobs

- Switches

- Lenses

- Consoles

- Heat sinks

- Fixtures

- Heat sinks

- Electronic devices

- Personal wellness products

- Athletics and sporting equipment

- Cookware products

- Wearable devices

- Accessory components

- Personal electronic devices

- Personal wellness products

- Cookware products

- Oral health products

- Smart home and IoT products

- Home furnishings

Whom we service for?

- Consumer electronics makers

- Appliance manufacturers

- Personal and household goods manufacturers

- Food and beverage companies

- Alcohol companies

- Athletics equipment manufacturers

- Toy manufacturers

Consumer Products Manufacturing Capabilities

EPRO offers wide range of manufacturing processes for Consumer Products prototypes and production parts.

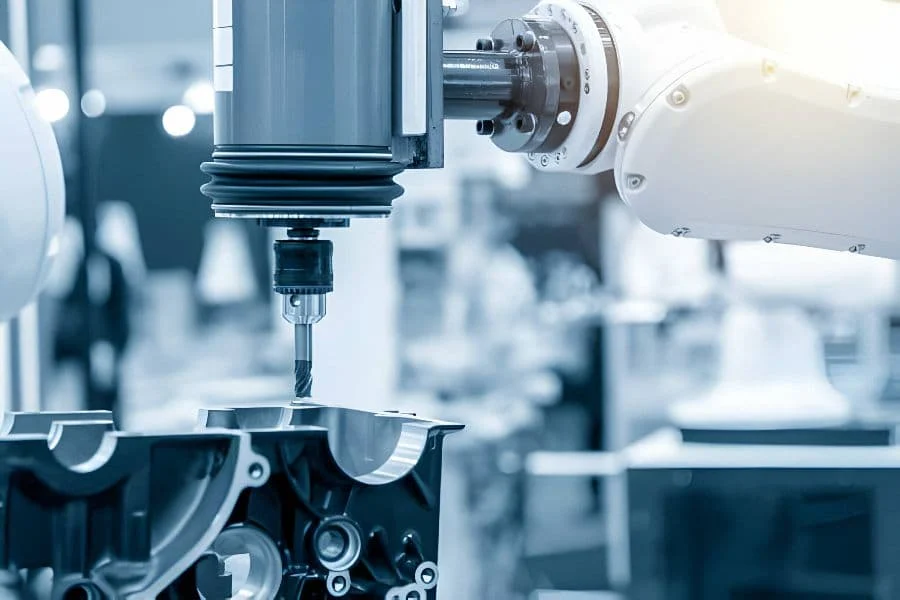

CNC Machining

By using CNC milling & turning, we can make a wide range of prototypes and production parts

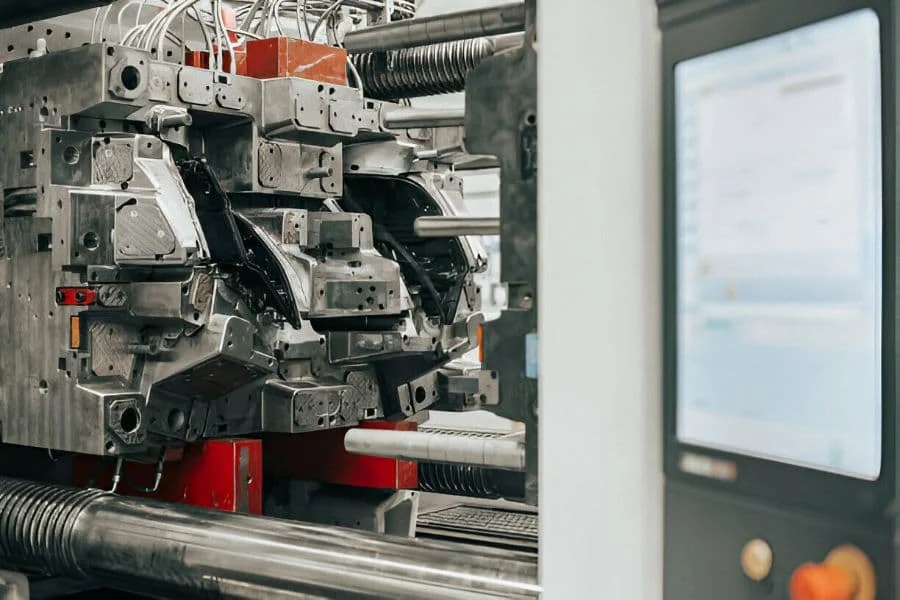

Injection Molding

We offer low-volume prototype moldings and mass production moldings.

3D Printing

We provide 3D printing services using a range of cutting-edge additive manufacturing technologies for metal or plastic parts

Sheet Metal Fabrication

Laser cutting, bending, stamping, spinning, punching, welding.

Consumer Products manufacturing materials

We offers wide variety high level surface finishes. We only list some of the common finishing options. There are more finish options for custom parts for Aerospace and defense Industry.

Consumer Products manufacturing materials

| Image | Material | Best Tech. | Benifits | Sample Parts |

|

Steel | CNC machining, rapid tooling | Strong, corrosion-resistant, range of grades | Brake components, engine components |

|

Aluminum | CNC machining, rapid tooling, sheet metal | Machinable, strong, range of grades | Cylinder heads, manifolds, Ductwork, housings, bus ducts |

|

Titanium | CNC machining, SLM 3D printing | Lightweight, temperature-resistant | Engine valves, axle shafts, pipes, nuclear waste storage, pumps, turbines |

|

PA(Nylon) | CNC machining, SLS 3D printing, injection molding | Strong, smooth surface finish | Peripheral engine parts, covers and housings |

|

PMMA | CNC machining, injection molding | Transparent, shatter-resistant | Lighting components |

|

|

Silicone | Liquid silicone injection molding | Durable, flexible, biocompatible, inert | Seals, cover assemblies, Fluid management devices, respiratory devices |

Applicable Finishes For Consumer Products Industry

We offer a huge range of material possibilities with all our manufacturing processes. Some common choices for aerospace and defense projects are listed below.

| Image | Item | Applicable To | Feature | Color | Thickness |

|

As machined | Metals & Plastics | Tool marks visible | N/A | N/A |

|

Polishing | Metals & Plastics | Brushed & gloss mirror surface | N/A | 0.02-0.05mm removed |

|

Sand, Bead Blasted | Metals & Plastics | matt or satin surface | N/A | N/A |

|

Painting | Metals & Plastics | Matt, gloss, texture | colors can be matched as needed | 0.05mm to 0.1mm |

|

Powder coating | Metals | Matt, gloss, texture | colors can be matched as needed | 0.05mm to 0.15mm |

|

Anodization | Aluminum | Tool marks visible, Smooth, Matt & Gloss | colors can be matched as needed | 0.002mm to 0.04mm |

|

E-Coating | Metals | Matt & Gloss | Black | 0.015mm to 0.035mm |

|

Nickel Plating | Metals | Gloss | Silver | 0.004mm to 0.05mm |

|

Chromed Plating | Metals & Plastics | Satin & Gloss | Silver | 0.001mm to 0.3mm |

|

Zinc Plating | Metals | Gloss | Silver & Black | 0.005mm to 0.2mm |

|

Chromate Conversion Coating | Aluminum | Tool marks visible, Smooth and Matt | Clear/ slight yellow tint | 0.25-1 um |

Put your parts into production today

All information and uploads are secure and confidential.

Tour Our 5 Axis Machine Shop

Check out our incredible line of well-functioning 5-axis machining centers ranging from the best 5-axis horizontal machining center to top-notch vertical machining centers. These are ideal facilities for manufacturing components for various industries. We combine advanced technologies with skilled technicians to deliver results to suit your needs perfectly.

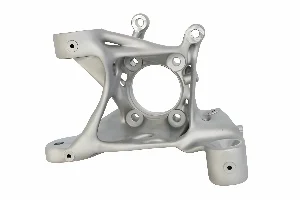

Gallery Of Consumer Products Parts