Metal Stamping Services

Sheet metal stamping: what is it?

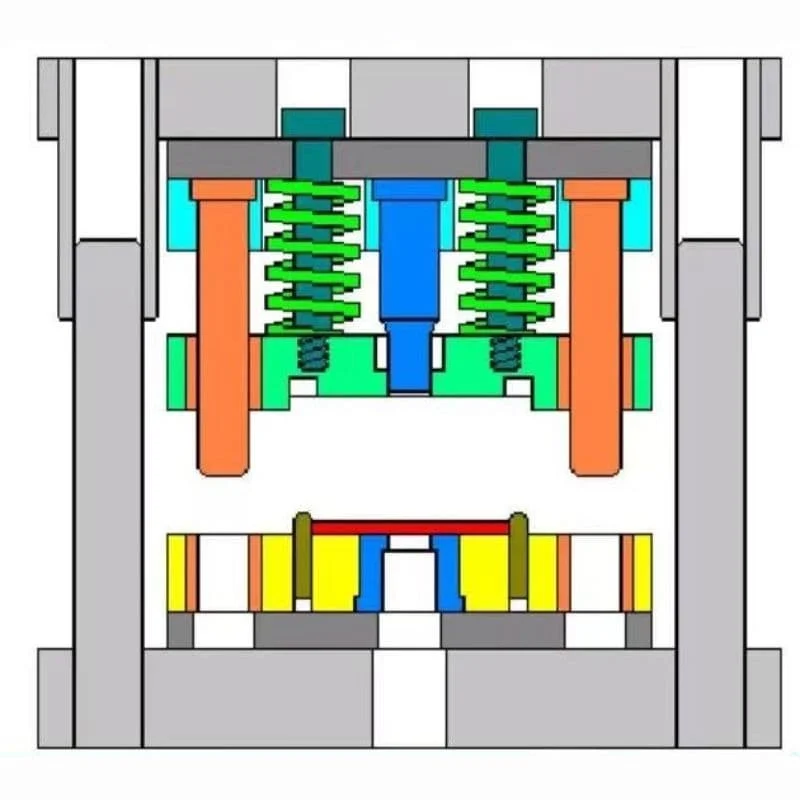

Metal stamping is a manufacturing process that shapes flat metal sheets. A stamping press is used to place flat sheets of metal, either coils or blanks, into it. A tool and die surface form the metal into the desired shape in the press. A number of metal forming techniques are involved in this process, including blanking, punching, bending, and piercing. From automobile components to electronic parts, stamping can be used to create a wide variety of products. It is a cost-effective and efficient production process that produces high-quality parts quickly.

Metal stamping advantages

Accuracies

Precision makes stamping stand out. Our meticulous process allows us to fabricate metal shapes with the smallest possible chance of error. Metal stamping accuracy is critical in industries like aerospace and electronics. The resulting high-quality, reliable products are consistently sized.

Affordability

Metal stamping can increase production speed while reducing processing time. Metal stamping reduces production costs by reducing the use of multiple machines, the number of workers, and the amount of labour. Companies can save money by using this technique in bulk orders. Because metal stamping produces parts quickly and efficiently, it is highly cost-efficient.

Process automation and value addition

A high-volume job must consider cost, quality, and volume. High-volume metal stamping is easy to do due to automation. Automated nut insertion can also be added as a secondary operation. High-volume metal stamping can be cost-effective and efficient. Using metal stamping offers fast and accurate manufacturing due to its automated processes.

Metal Stamping Solutions

EPRO offers superior metal stamping services, creating high-quality metal components and products from your designs. As a leading provider of custom metal stamping, we are dedicated to quality, accuracy, and speed. Here is a brief overview of the services we offer to ensure the success of your project.

Material

• Aluminium (5052, 6061, 6063, 1060)

• Carbon Steel (SPCC, HRS, SAPH440)

• Stainless Steel (201, 304, 316)

• Cold Galvanized Steel

Thickness

• 0.1mm to 6.0mm

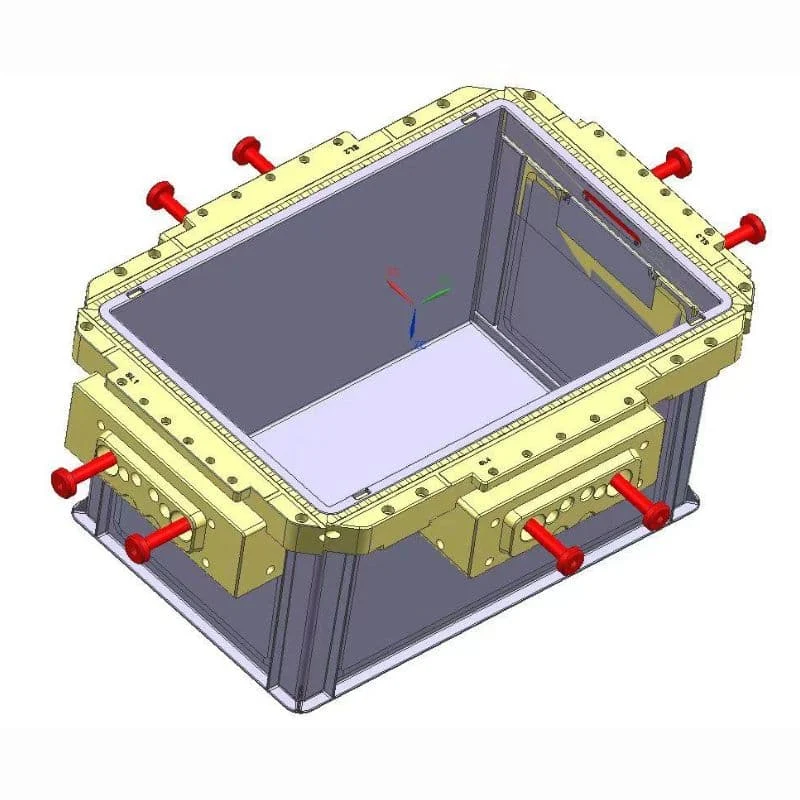

Stamping Dies

• Regular Die

• Progressive Die

Equipment

• Stamping Presses: 16T, 25T, 40T, 63T, 80T, 160T, 200T

• x 2 Material Auto-feeders

Surface Finishing

• Powder Coating | Painting

• Anodizing

• Electro Coating

• Zinc Plating

• Hot Dip Galvanized

• Passivation

• Sandblasting

Secondary Processes

• Assembly Services

• TIG and MIG Welding

• Spot Welding

• CNC Sheet Bending

• Riveting

• PEM

• Laser Etching

Type of metal stamping

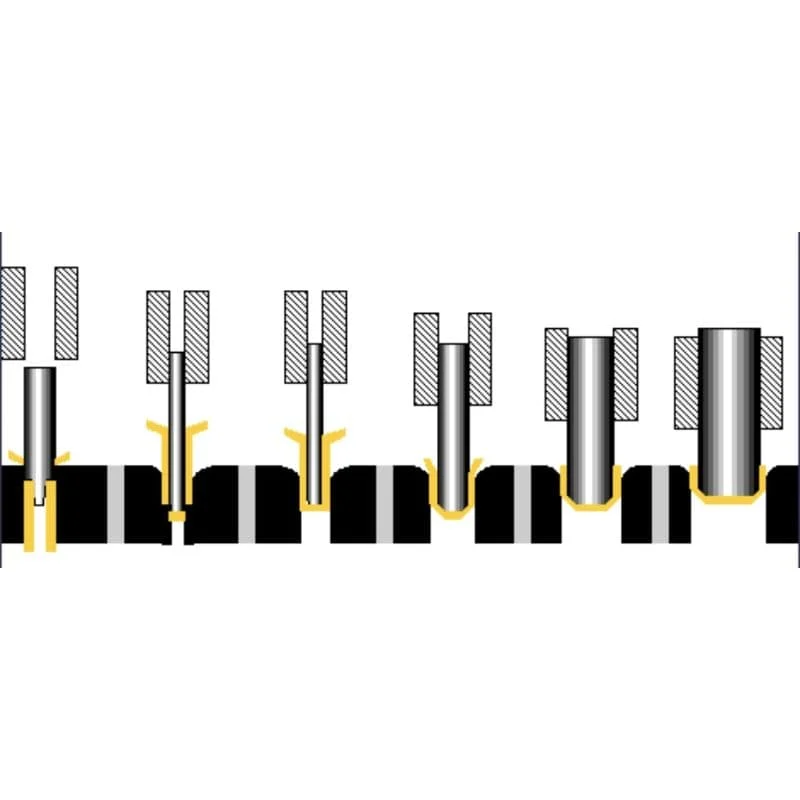

Progressive Die Stamping

An occupied press may need to change tools repeatedly, or a number of presses may perform one action at a time to complete a part. Secondary machining was often required even when using multiple presses. For metal parts with complex geometry, progressive die stamping is the perfect solution to meet the following requirements:

- Getting the job done faster

- Labor cost reduction

- Reduced run time

- Increased repeatability

Fourslide Stamping

Many applications are ideal for fourslide metal stamping because it offers several advantages over traditional press stamping. A four-slide stamping machine is an efficient way to produce complex parts with tight tolerances. As a result, prototyping can be done more quickly and production runs can be reduced. There are also some advantages to this process, such as requiring less tooling and reducing the number of manufacturing steps.

- Parts that require more versatility

- Changes in design are more flexible

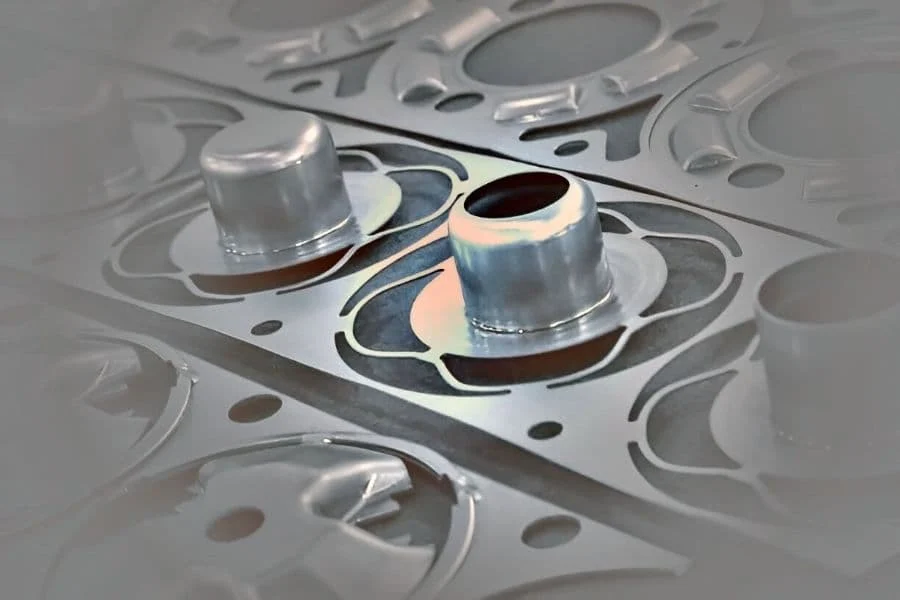

Deep Draw Stamping

Forming is a cost-effective alternative to turning processes, which typically consume more raw materials and are ideal for creating components with several series of diameters. Due to the fact that die casting uses a single die to produce multiple components simultaneously, the production cost is reduced.

Short Run Stamping

For prototypes and small projects, short run metal stamping is an ideal solution. For many projects, particularly those with a rapid turnaround, short-run production is more economical, despite smaller run sizes and custom forming. As compared to long-run production, short-run stamping provides more flexibility in design and shorter lead times. Due to its greater accuracy, repeatability, and tolerance, it is the ideal choice for more complex projects.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

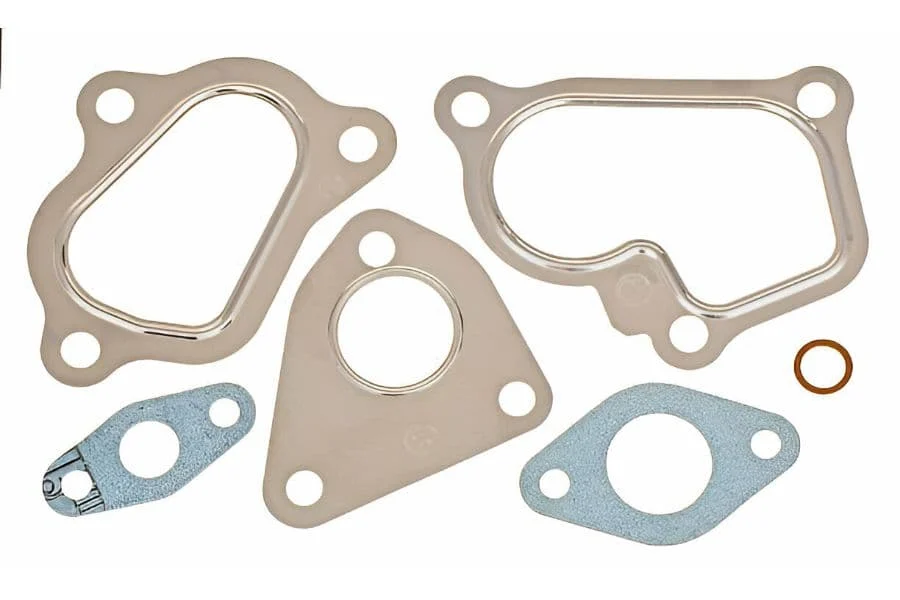

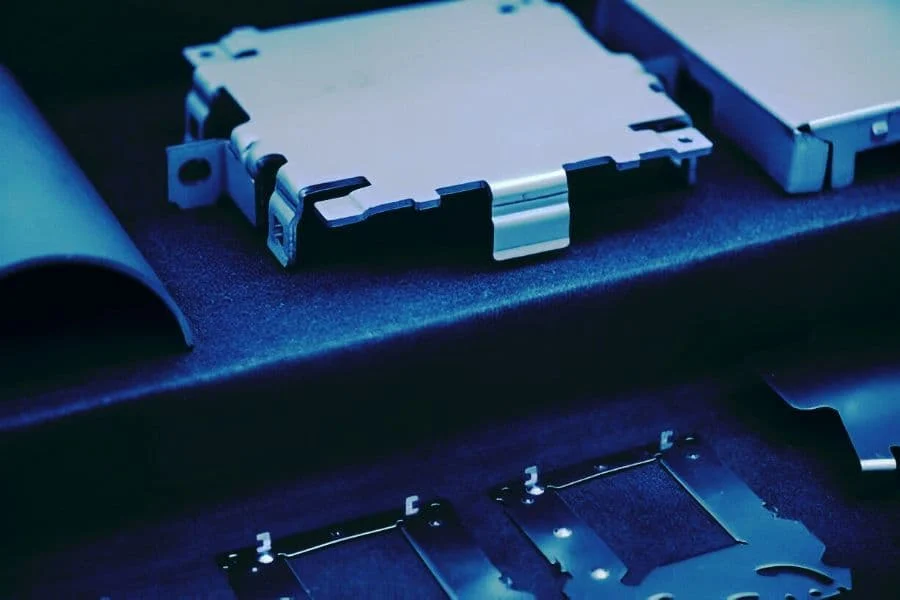

Applications for Metal Stamping Parts

Metal stamping is used to create intricate connectors for electronic devices. It provides durable components for washing machines and refrigerators. A medical instrument to an aerospace component must be precise and efficient to be successful. From hardware to fashion accessories, it shapes consumer goods. A wide range of industries rely on metal stamping to create reliable, customized, and intricate components.

Aerospace & Defense

It is important to fabricate metal stamping with precision for aerospace and defense projects. Whether it is aircraft components or military hardware, our expertise ensures that each piece meets the highest standards of durability, reliability, and performance, essential for demanding applications.

Automotive

With our metal stamping, you can revolutionize your automotive designs. A variety of lightweight, yet robust components are produced using our advanced fabrication techniques, which meet the stringent requirements of the automotive industry, from chassis components to body panels.Let’s call EPRO Today!

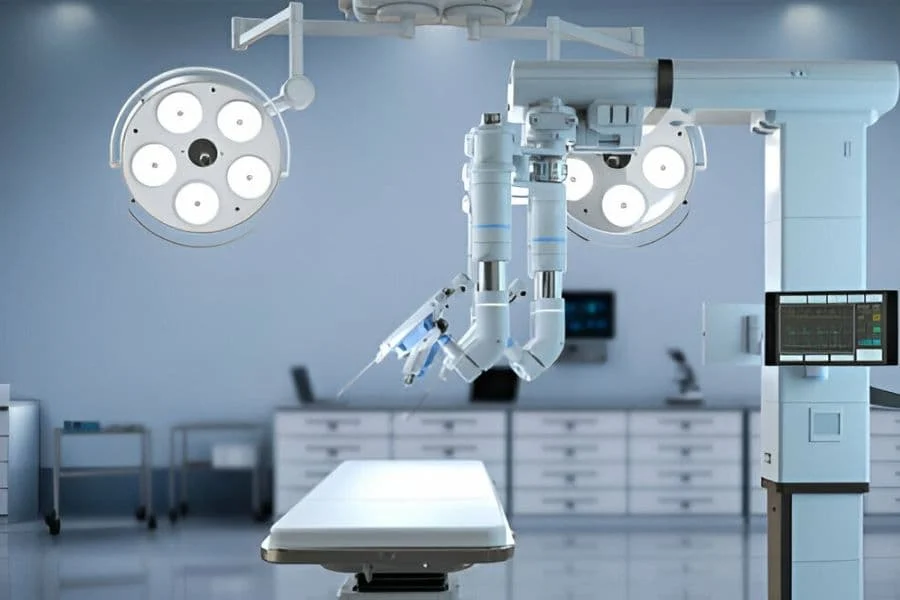

Medical

Our metal stamping are trusted for critical medical equipment and devices. The precision manufacturing capabilities of our facility ensure compliance with strict regulatory standards while maintaining the highest levels of hygiene and sterilizability for intricate parts such as enclosures, trays, and surgical instruments.

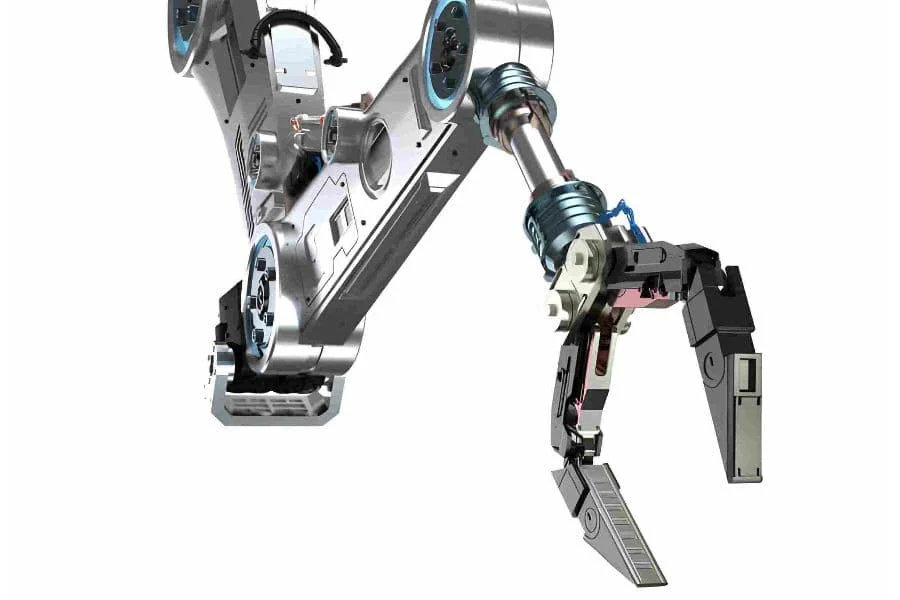

Robotics and Automation

We provide precision metal stamping for robotics and automation systems. Our robotic and automated components, including structural frames, enclosures, and brackets, are designed for seamless integration and optimal functionality.Let’s call EPRO Today!

Consumer Products

With our versatile metal stamping, you can enhance your consumer products. We provide high-quality, aesthetically pleasing parts that meet consumer demands for durability, functionality, and modern design in electronic enclosures and household appliances.

More Industries

Design services

New energy

Electronics & Semiconductor

Education

Industrial Machinery & Equipment

Supply Chain and Purchasing

Tips for Sheet Metal Stamping Parts

You should choose the right material for your specific application, taking into account factors such as strength, durability, and corrosion resistance. Streamline the stamping process by minimizing intricate features and sharp angles. Provide clear instructions for the stamping machine in your design files. Ensure they are accurate and complete. Optimise efficiency and quality by collaborating with our team to leverage their tooling expertise.

Take a tour of our metal stamping workshop

Stamped metal parts are the result of precision-tuned machinery and skilled craftsmanship. In the workshop, high-quality components are created by seamlessly blending technology and expertise. Discover our commitment to quality and our advanced stamping machines for yourself. Discover our metal stamping services on this immersive tour, where every stamp reflects our commitment to precision, efficiency, and quality.

Stamping Parts Made by EPRO-RAPID

Check out our display of Sheet Metal Parts. At EPRO, you can confidently get the best Sheet Metal parts!