Custom Plastic Extrusion Services

Plastic Extrusion: What Is It?

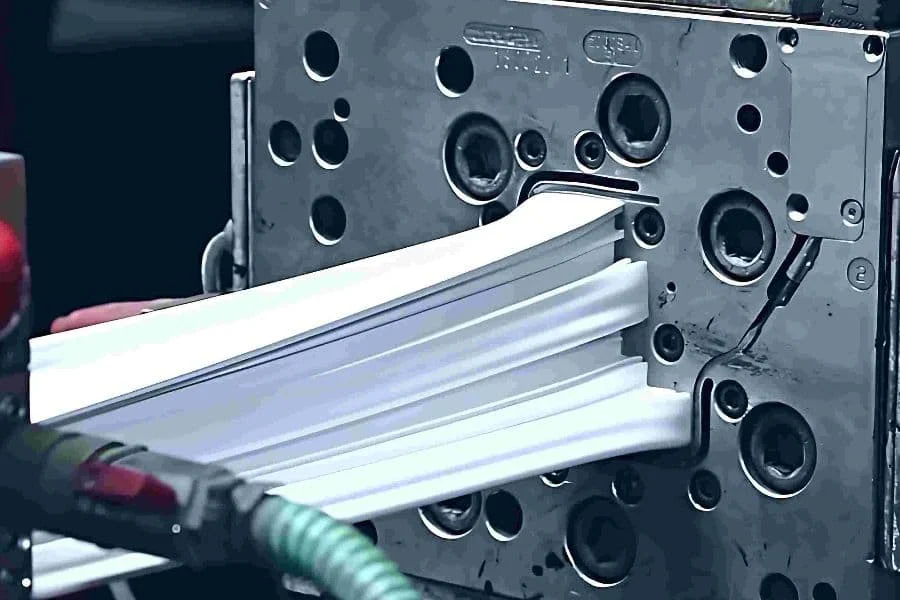

Plastic extrusion is a high-volume manufacturing process which involves homogeneous melting of a thermoplastic material in order to produce the desired product. The melted material could be in the form of pellets, powder, or granules. After a sufficient amount of pressure is applied, the melted material leaves the hole in the shaping die.By passing through the extruder, melted plastic acquires the shape of the die hole. It is possible to machine and shape plastic further once it is cooled. Extrusion is pulled at a constant rate, cooled (usually in water), and cut into standard lengths for sale and distribution. Construction, utilities, telecommunications, and other industries rely heavily on plastic extrusions.

Plastic extrusion's advantages

After Extrusion Manipulation

After extrusion and cooling, plastic can still be shaped. Manufacturers can ensure high-quality products by giving them this flexibility. This technique allows manufacturers to create complex shapes with minimal waste. Customer demands can be quickly met by changing production processes.

Relatively Cheap

Extrusion is a cost-effective method of developing plastic. It does not require elaborate tooling. Speed and efficiency reduce production costs with plastic extrusion. This is why many companies use plastic extrusion for plastic components.

A flexible approach

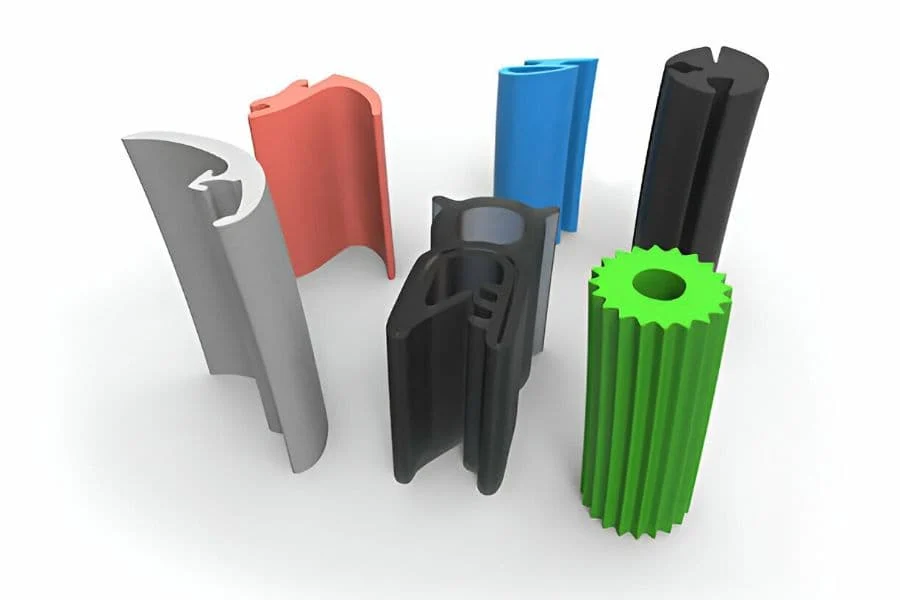

Plastic extrusion is flexible because of its consistent cross-section. Profiles can produce intricate shapes if their cross sections remain constant. There are many industries that can benefit from this. Plastic extrusion is cost-effective and efficient for many businesses.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

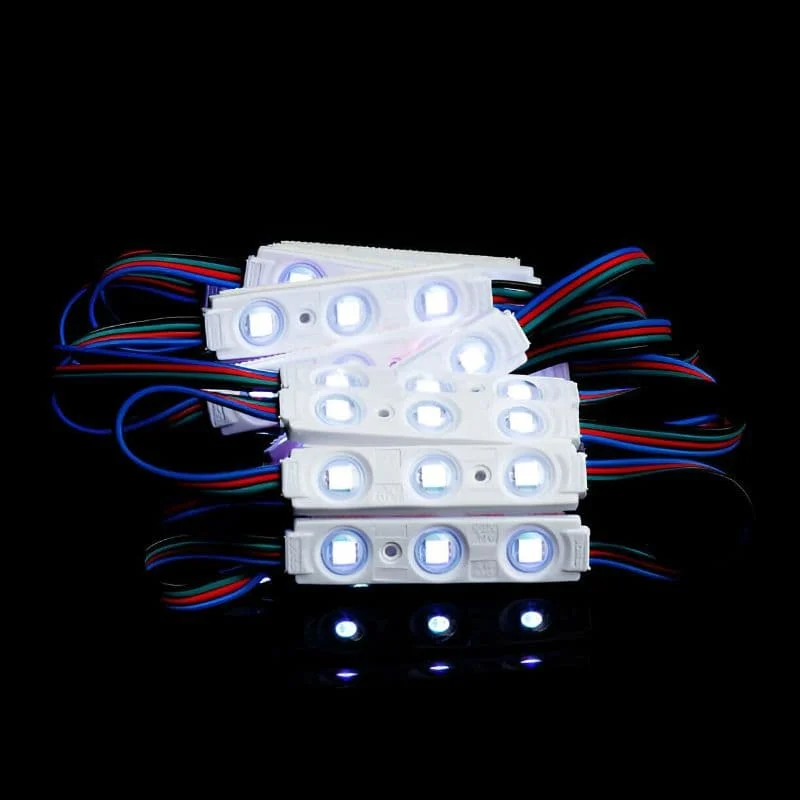

Custom Extrusion Applications

Extrusion of plastic is a cornerstone in a wide variety of industries, providing custom solutions with precision. Its versatility shapes the future of construction, packaging, automotive, and medical devices. Innovative solutions in diverse industrial landscapes are driven by the versatility and efficiency of plastic extrusion.

Plastic Extrusion Material Options

Our product line includes more than 100 thermoplastic and thermoset materials. You can also find resin substitutes for ABS, PC, PP, and other commonly molded plastics in our resin substitutes guide. There is also an application list for each material in our guide. Moreover, we offer custom molding options for these materials so you can get the exact product you need.

- ABS (Acrylonitrile Butadiene Styrene)

- Acrylic

- PVC (Polyvinyl Chloride)

- Flexible PVC (Polyvinyl Chloride)

- Rigid PVC (Rigid Polyvinyl Chloride)

- CPVC (Chlorinated Polyvinyl Chloride)

- Mineral Filled Polypropylene

- Polycarbonate

- TPA (Thermoplastic Alloy)

- Polyethylene

- TPV (Thermoplastic Vulcanizate)

- Polypropylene

- Styrene

View the material options

PVC (Polyvinyl Chloride)

Acrylic

ABS

Polycarbonate

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

Plastic extrusion tips

Learn how to maximize the efficiency and quality of plastic extrusion with expert tips. When choosing thermoplastic materials, keep strength, durability, and heat resistance in mind. To ensure consistent extrusion, ensure uniform wall thickness and minimize complex features. With the help of our experienced team, optimize extrusion parameters and die design.

Our plastic extrusion workshop is open for tours

Discover how plastic extrusion works in our cutting-edge workshop. Advanced machinery and expert craftsmanship are used to shape raw thermoplastic materials into bespoke profiles and components. From custom designs to intricate shapes, we ensure top quality at every step. Join us on this immersive tour of our plastic extrusion services, which are the pinnacle of efficiency, precision, and excellence.

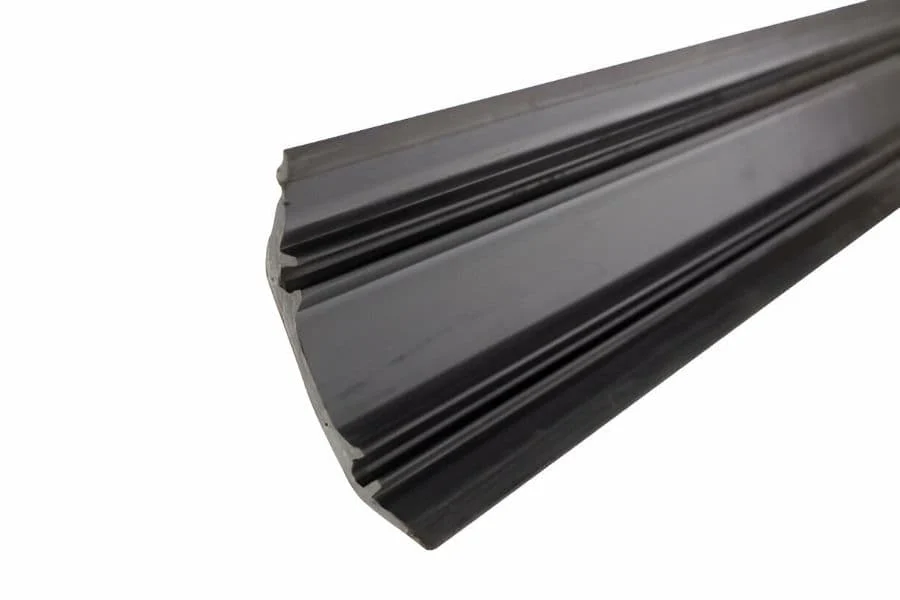

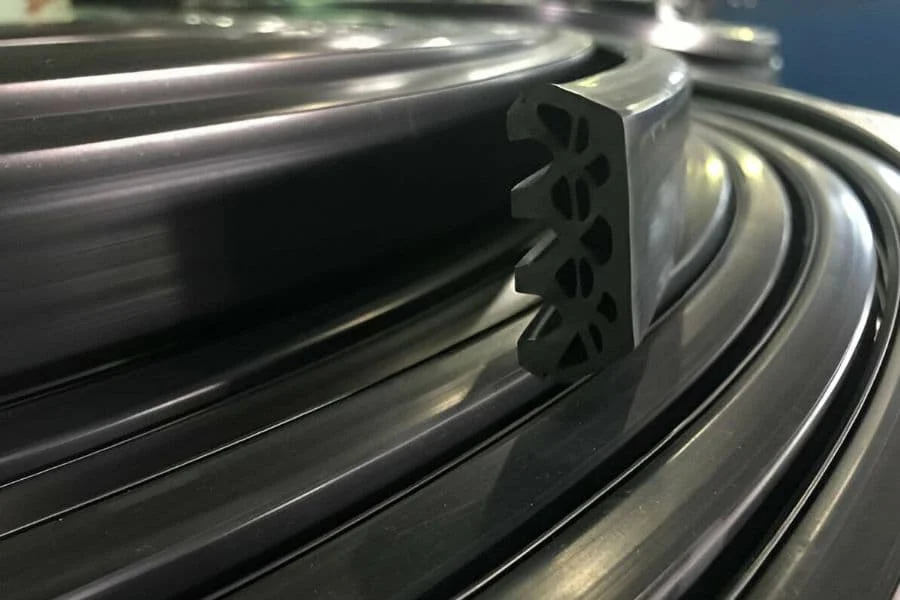

Example of Plastic Extrusion Parts

Check out our display of Plastic Extrusion Parts. At EPRO, you can confidently get the best Plastic Extrusion parts!