Custom Metal Bending Services

Sheet metal: how does it work?

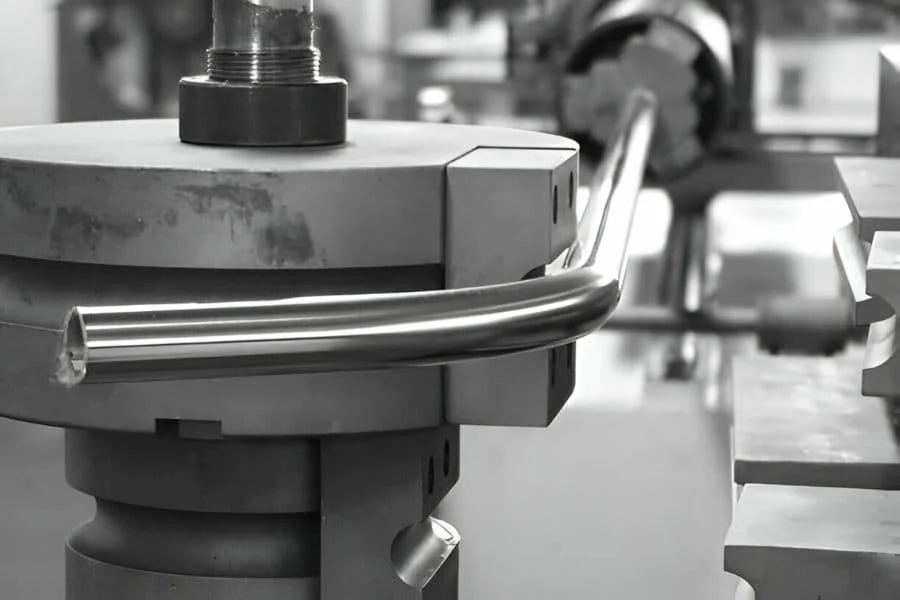

In sheet metal fabrication, bending is commonly used to produce V-shapes, U-shapes, and channel shapes along straight axes. Press brakes are specialized machines that are used for this process. A lower die and an upper die are used to bend sheet metal on these machines. In the next step, the sheet metal is formed into the desired shape.Among the shapes that can be formed by bending machines are curves, angles, and circles. Their ability to produce parts with a high degree of accuracy and consistency is impressive.

Air bending, bottoming, and coining are among the bending techniques that can be performed using this equipment. Air bending is the most common type of bending and is most effective for large parts.

Automotive or aircraft panels, electrical enclosures, storage units, cabinets, and many other types of products are bent by many manufacturers. A hydraulic press and a press brake are also used as part of this process.

In low to medium quantities, bending produces lightweight parts with good mechanical properties. A relatively simple process, it only requires minimal equipment and basic operator skills. Sheet metal can also be formed into complex shapes using this method.

Our Sheet Metal Services

We manufacture sheet metal parts by laser cutting, water jetting, or chemically etching blanks.For prototypes and large production runs, we have state-of-the-art facilities. You can rely on our sheet metal services to meet your production needs.

Manufacture speed

Due to a lack of tools and high levels of automation, sheet metal parts can be designed and manufactured very quickly, allowing large volumes of components to be produced in a very short time.

Precision

It is possible to get high accuracy with laser cut holes. Laser cutting and bending are also faster than traditional machining.

Cost Effective

Lower assembly, installation, and maintenance costs. Additionally, it is more cost-effective since bends require less machining or welding thanks to the complexity of bends available.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

Sheet Metal Bending Services We Offer

We have a wide range of capabilities, from simple to complex bends, and our experienced technicians can provide guidance to ensure the best results. Structural steel bending can be used to create a variety of shapes, including curves, angles, and straight lines.

We offer high-quality bending services to companies that require these operations.Which including:

- The cambering of beams

- Bending structural steel

Companies in many industries can take advantage of these options including:

Shipbuilding, aerospace, automotive, and construction.

- Fabricators of structural steel

- Contractors in public works

- Companies that manufacture equipment

- The shipbuilding industry

- Other Parties

Metal Bending Capabilities

EPRO offers ISO 2768-compliant sheet metal bending services for prototypes and production parts. We combine highly advanced metal bending machines with high-quality technicians to achieve precision bending. We can handle rapid prototyping and mass production. We put customer satisfaction first when bending sheet metal. We strive to provide our customers with the best value. We provide quality results on time and at an affordable price.

| Standards | Description |

| Maximum Part Size | 1.5 m x 1.5m |

| Metal Bending Forces | Up to 1000 tons |

| Bending Line Length | Up to 7200 mm |

| Bending Thickness | Up to 60 mm |

| General Tolerances | Our metal bending standards depend on ISO 2768. |

| Bend to edge/hole, single surface | +/- 0.254 mm (+/- 0.010 in.) |

| Bend Radius | Be equal to material thickness |

| Bend Angle | +/- 1° |

| Bending Cutting Area | Up to 4000 mm |

| Lead Time | 5 days or more |

Metal Bending Materials List

EPRO-Rapid’s metal metal bending service supports the following metal materials. There may also be other materials available for quote. To discuss your specific needs, please contact our team. If you would like advice on how to bend your materials, we can provide it.

Aluminum

- Aluminum 2024-T3

- Aluminum 5052 H32

- Aluminum 6061 T6

- Aluminum 7075 T6

- Aluminum MIC6

- Pre-Anodized 6061-T6, Black

Steel

- Hot Rolled Steel 1045

- Hot Rolled Steel A569

- ASTM A1011

- Steel 1008, zinc-galvanized

- Steel 1018

- Steel 4140, hardened

- Steel A36

- Steel A36, pickled and oiled

- Steel A366/1008

Stainless Steel

- Stainless Steel 17-4 PH, annealed

- Stainless Steel 301, spring temper

- Stainless Steel 304

- Stainless Steel 304 shim, hardened

- Stainless Steel 304, #4 brushed

- Stainless Steel 316

- Stainless Steel 410, annealed

- Stainless Steel 430, #3 brushed

- Stainless Steel 440C

Other

- Brass 260

- Bronze 220 H02

- Copper 101, H00 to H01

- Copper 110, Annealed

- Nickel 625, annealed

- Titanium (Grade 2)

- Titanium 6Al-4V (Grade 5)

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

Sheet metal bending applications

Sheet metal bending is a key component of these diverse industries that allows precise, customized components and structures to meet the specific needs of each.Due to its versatility and precision, sheet metal bending is widely used across various industries.

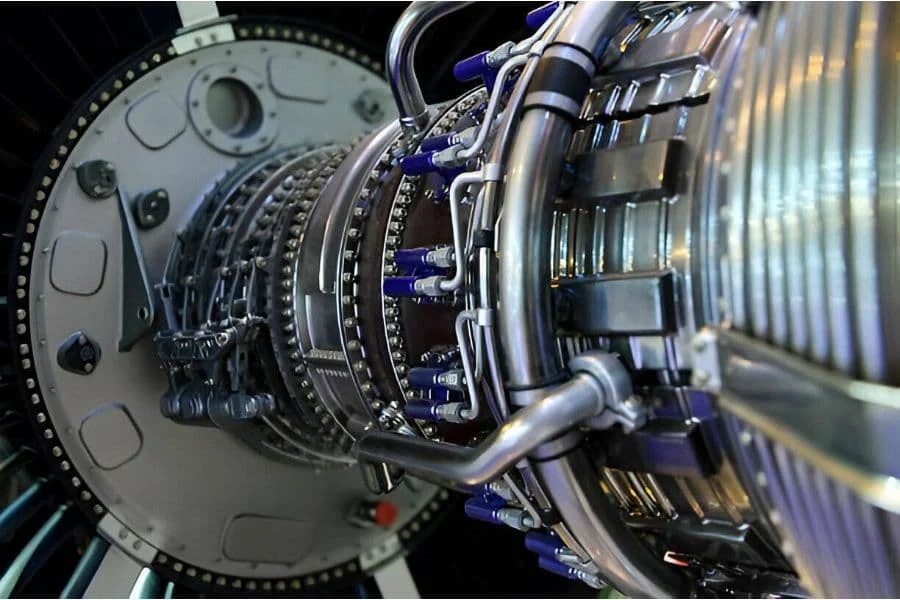

Aerospace & Defense

It is important to fabricate metal bending with precision for aerospace and defense projects. Whether it is aircraft components or military hardware, our expertise ensures that each piece meets the highest standards of durability, reliability, and performance, essential for demanding applications.

Automotive

With our metal bending, you can revolutionize your automotive designs. A variety of lightweight, yet robust components are produced using our advanced fabrication techniques, which meet the stringent requirements of the automotive industry, from chassis components to body panels.Let’s call EPRO Today!

Medical

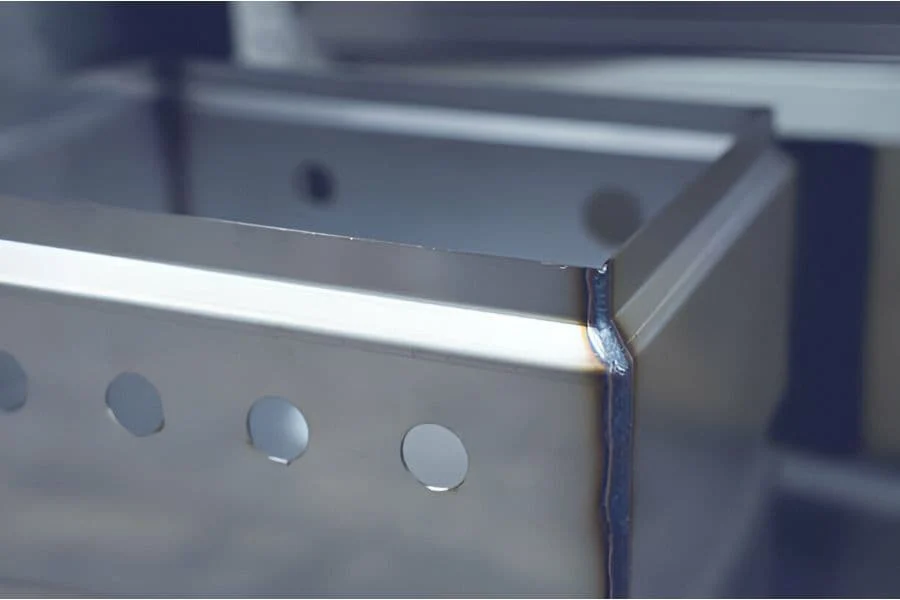

Our metal bending are trusted for critical medical equipment and devices. The precision manufacturing capabilities of our facility ensure compliance with strict regulatory standards while maintaining the highest levels of hygiene and sterilizability for intricate parts such as enclosures, trays, and surgical instruments.

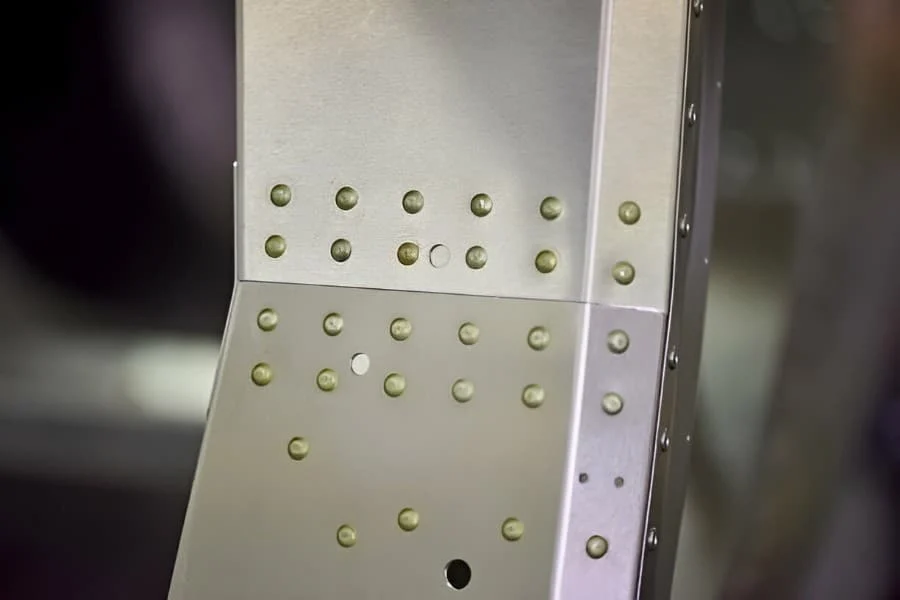

Robotics and Automation

We provide precision metal bending for robotics and automation systems. Our robotic and automated components, including structural frames, enclosures, and brackets, are designed for seamless integration and optimal functionality.Let’s call EPRO Today!

Consumer Products

With our versatile metal bending, you can enhance your consumer products. We provide high-quality, aesthetically pleasing parts that meet consumer demands for durability, functionality, and modern design in electronic enclosures and household appliances.

More Industries

Design services

New energy

Electronics & Semiconductor

Education

Industrial Machinery & Equipment

Supply Chain and Purchasing

Sheet metal bending tips

It is crucial to select the right material first and foremost. Based on your project’s requirements, choose the right sheet metal by considering thickness, type of material, and specific properties. It is also important to select the right tools to ensure accuracy and efficiency.It is crucial to understand the limitations and capabilities of sheet metal bending machinery. Leverage our experienced team's expertise by collaborating closely with them. Optimize efficiency and achieve desired results by considering factors such as the machine's tonnage, tooling options, and bending length.

Tour Our sheet metal bending Shop

Our advanced bending machines can handle various sheet metal materials and thicknesses. Regardless of the material, our sheet metal bending workshop is the preferred choice for precise bending solutions. Get a first-hand look at each piece being bent with meticulous attention to detail and expertise. Find out how we’re shaping tomorrow’s innovations today.

Gallery Of Metal Bending Parts

Check out our display of Metal Bending Parts. At EPRO, you can confidently get the best Metal bending parts!