Rapid Mold Tooling Services

What Is Rapid Tooling?

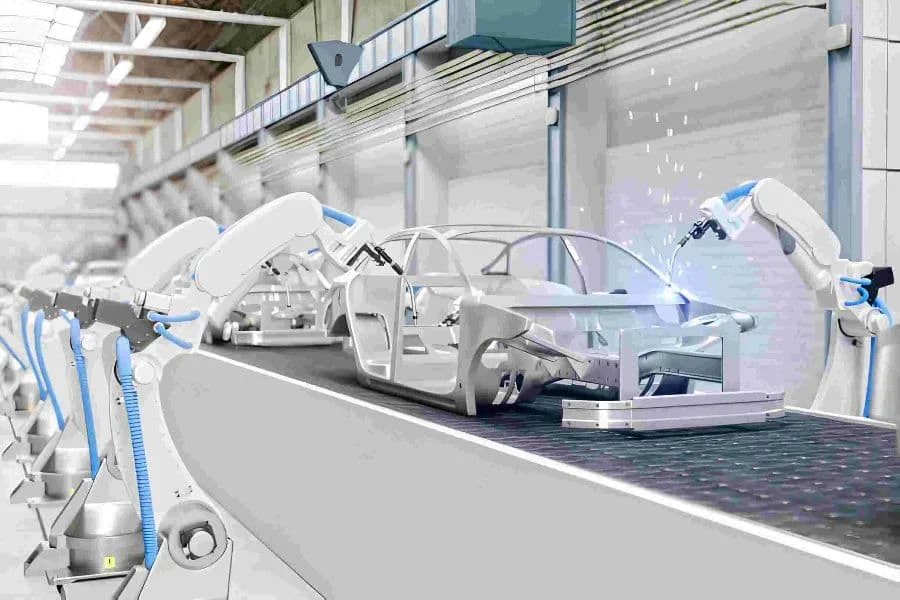

Rapid tooling is a manufacturing process of mold or tools that helps use specialized techniques and equipment to quickly create prototypes and production-grade parts. It is often used to create molds, dies, and other tools used to produce plastic or metal parts. Rapid tooling can create prototypes and production parts for various industries, including automotive, aerospace, medical, and consumer products.

One of the primary advantages of rapid tooling is that it reduces production time and cost. Because rapid tools are quick and easy to replicate, finished tools require less stock. However, the disadvantages are that it is less precise and reduces the product’s lifespan. Rapid tooling is an excellent method for developing small-batch orders in process design, marketing, and product evaluation.

Advantages of Rapid Tooling

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

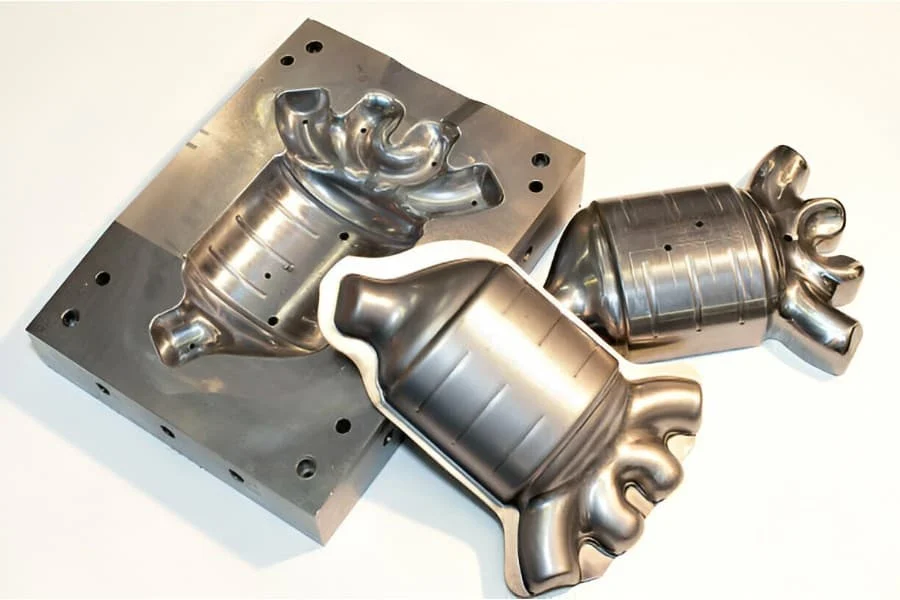

Creating custom molds

- Molds of any dimension can be quickly created with rapid tooling. Molds produce parts with different grades of material and test their properties and quality, helping you choose the right material.

Getting to market faster

- Rapid tools need fewer steps than conventional tools methods. The sooner you finish the prototype and prototyping, the sooner you can finish your designs and give them to your clients.

Make Costs Cheaper

- Longer development costs more. Companies can save money with rapid tooling. Furthermore, rapid tooling reduces design iterations and costs. Faster and more efficient product creation can lead to a competitive advantage.

Parameter testing for processes

- Rapid tooling can also be used to test process parameters. Different injection rates and mold temperatures can affect part quality. Measurements can be controlled more easily with rapid tooling.

Reduced resource consumption

- Rapid tooling requires very little production or prototyping. One mold or tool can create multiple prototypes. We eliminate machining and injection molding, which are time-consuming and costly. Additionally, this method is less costly and time-consuming.

Design and Functionality of Tests Thoroughly

- Rapid tooling allows you to make several prototypes or molds quickly. You can experiment with new ideas as well as tweak old ones. This will prevent many problems during future high-volume production phases.

How does rapid tooling work at EPRO?

Choices abound

A variety of materials, finishes, tolerances, markings, and certifications are available for your order. We can accommodate any specifications you need. Our experts can help you select the right option. We aim to deliver an excellent product at a reasonable price.

Get expert advice

You don’t have to worry about sourcing, project management, logistics, or shipping with our experts. We ensure that our customers receive their parts in perfect condition and on time. Throughout the process, we provide guidance and support to our customers.

Network vetted

It is our pleasure to inform you that we are ISO 9001:2015, ISO 13485, and AS9100D certified.We review each Supplier’s qualifications, capabilities, and ethical standards using our system. Quality, safety, and reliability are our top priorities.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

Injection molding: why choose EPRO?

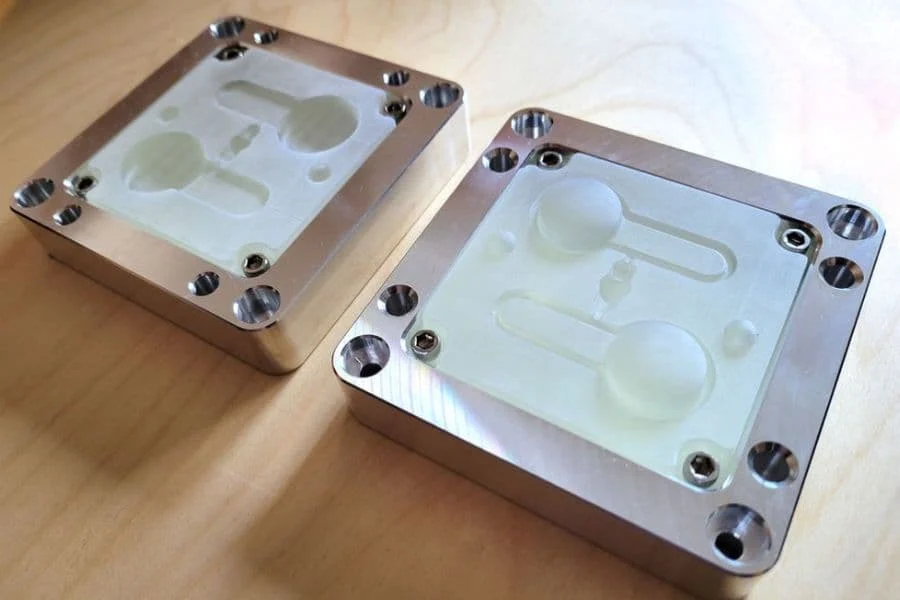

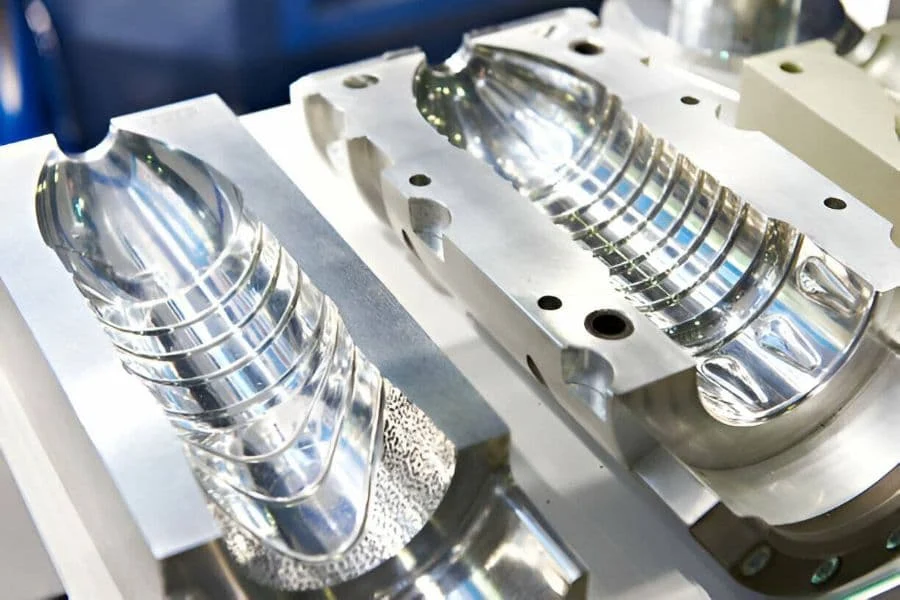

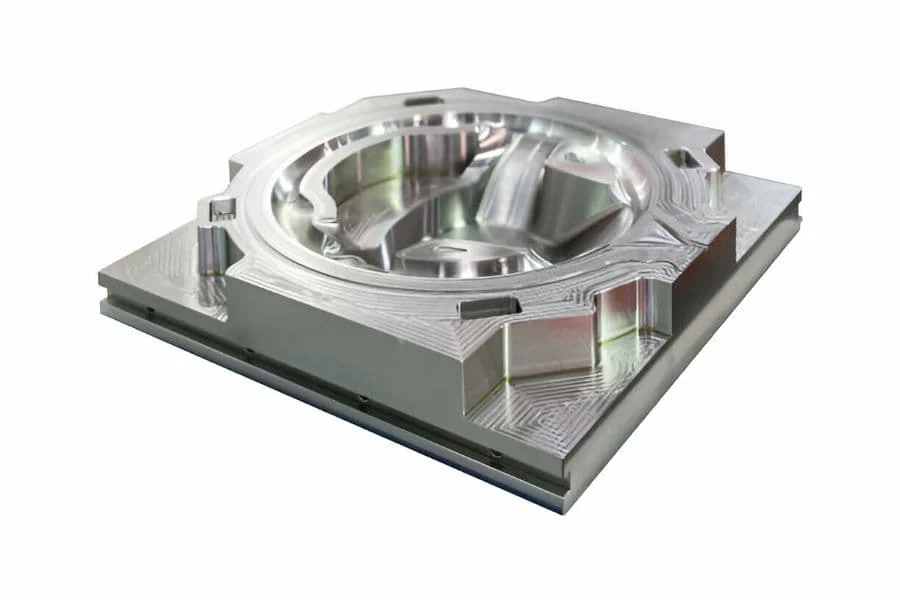

Aluminum Mold Tooling

Producing injection molded prototypes is cost-effective. Aluminum tooling reduces part deformations and waste production. Tooling costs are reduced by up to 25% by using aluminum molds. Reduces cycle times by 30-40%. This contributes to faster turnarounds. Aluminum molds are cost-effective, dimensionally stable, and have short cycle times, making them ideal for prototype injection molding.

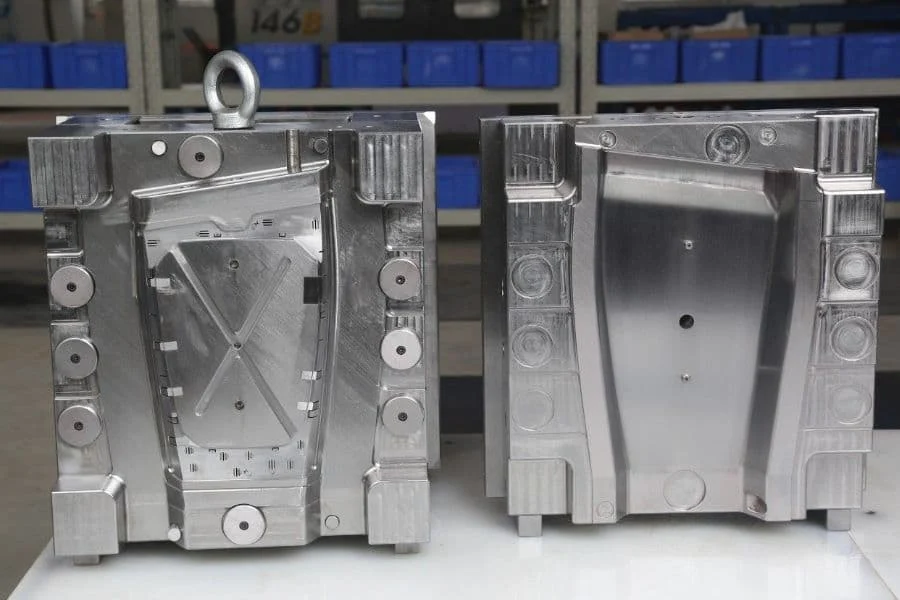

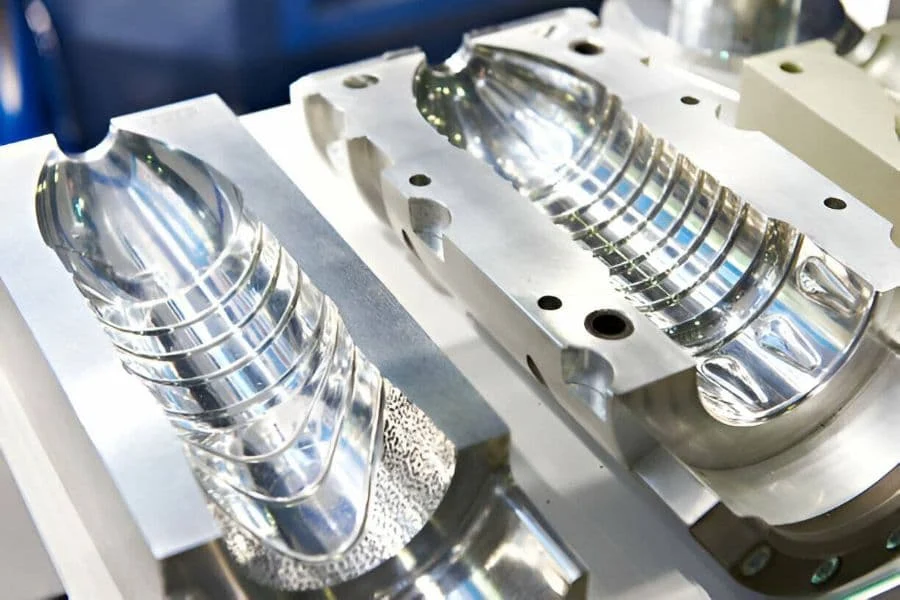

Steel Mold Tooling

Steel has a longer life cycle than other materials. This is best suited to high-volume production. It is more expensive and takes longer to produce mold tooling and prototypes than aluminum. It may not be the best choice for intricate projects because it is difficult to mold and shape. Steel also cannot be used for projects requiring lighter materials due to its weight. Steel is best used when producing large quantities and for engineering-grade plastic molds.

Rapid tooling materials

Take a look at our versatile selection of materials to learn more about rapid tooling. For prototyping and low-volume production, aluminum offers lightweight and cost-effective solutions. The durability and precision of tool steel makes it an ideal material for high-volume manufacturing. A stainless steel product ensures corrosion resistance and strength, making it the ideal material for demanding applications. You can achieve optimal results with these materials in your rapid tooling projects.

Aluminum

Aluminum molds cost substantially less than traditional steel and carbon steel injection molds. Aluminum molds offer faster cycles and quick turnaround to help test markets.

Type: 6061,5052,7075

Tool Steel

Before injection molding process starts low or high-volume production, a high tolerance CNC machined tooling is needed. Most commonly used materials include tool steel.

Type:P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

Stainless Steel

Injection molds were created from steel and stainless steel which are expensive to manufacture. They are typically only used in large-scale productions.

Type:420, NAK80, S136, 316L, 316, 301, 303, 304

Rapid tooling surface finishes

Expertly crafted surface finishes enhance both aesthetics and functionality of rapid tooling projects. Whether you want smooth mirror finishes or textured surfaces, we ensure superior quality and performance, so that your designs stand out to perfection.

Description of Glossy

A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts.

Description of Semi-glossy

B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture.

Description of Matte

C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture.

Description of Textured

D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish

Rapid tooling Capabilities

Unlock limitless possibilities with our rapid tooling capabilities. From quick turnaround times to precise mold manufacturing, we empower you to bring your designs to life with speed and precision. Experience innovation at its finest with our cutting-edge rapid tooling services.

| Mold Class | Purpose | Shot Life | Tolerance | Cost | Lead Time |

| Class 105 | Prototype Testing | Under 500 cycles | ± 0.02mm | $ | 7-10 days |

| Class 104 | Low-volume Production | Under 100.000 cycles | ± 0.02mm | $ $ $ | 10-15 days |

| Class 103 | Low-volume Production | Under 500.000 cycles | ± 0.02mm | $ $ $ $ | 10-15 days |

| Class 102 | Medium-volume Production | Medium to high production | ± 0.02mm | $ $ $ $ $ | 10-15 days |

| Class 101 | High-volume Production | Over 1,000,000 cycles | ± 0.02mm | $ $ $ $ $ $ | 10-18 days |

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

Rapid Tooling Tips:

Simplicity in design will speed up mold creation and reduce production costs. Consult with our experts to determine which materials are best for your application. Improve efficiency and production volume by using multi-cavity molds. The tooling process should be reviewed and refined regularly in order to ensure efficiency. By utilizing these insights, you’ll be able to unlock the full potential of rapid tooling, ensuring faster, more precise, and better results.

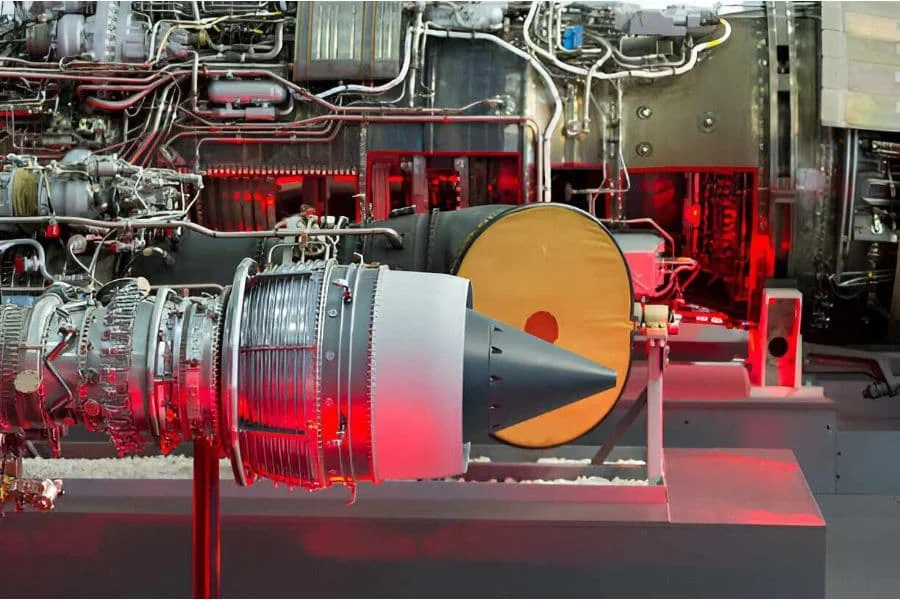

Rapid Tooling applications

The Rapid Tooling process has numerous applications across a wide range of industries. With its precision and efficiency, it is indispensable for automotive components, medical devices, consumer electronics, and more. In diverse sectors, this technology delivers high-quality and customized plastic products for a variety of industrial uses.

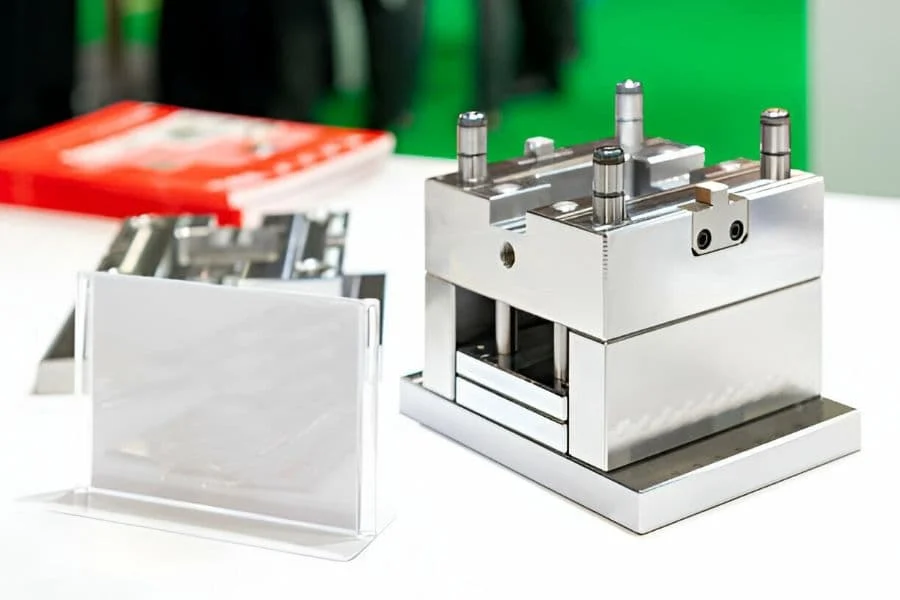

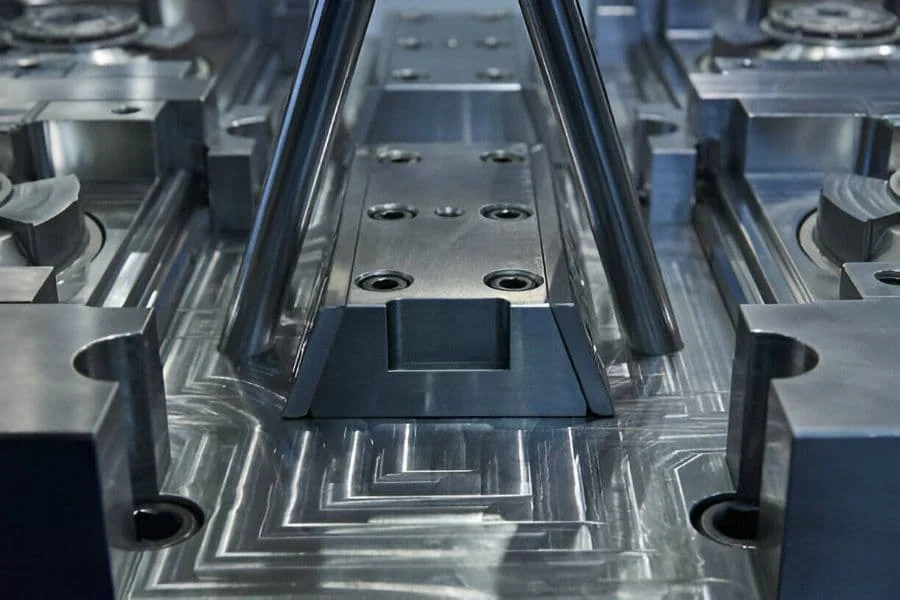

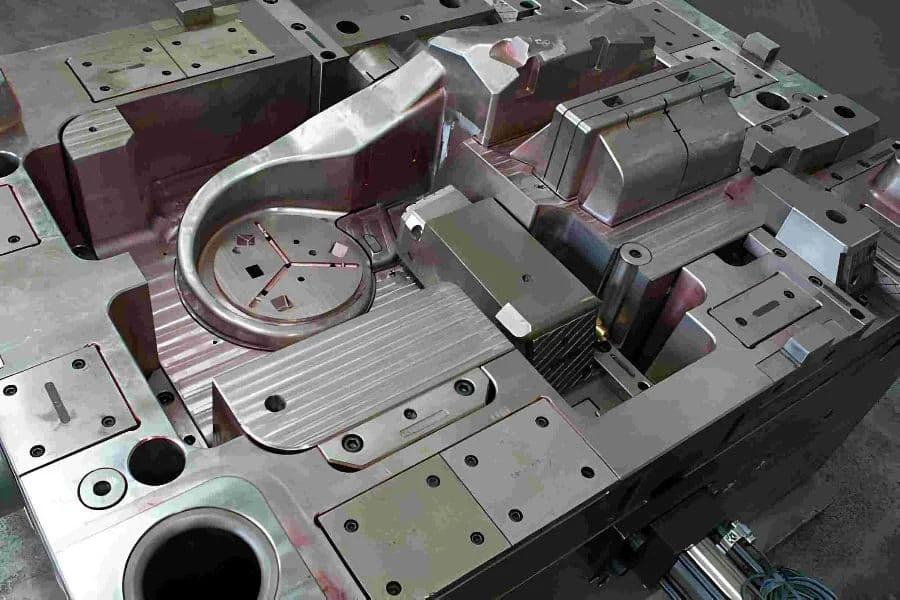

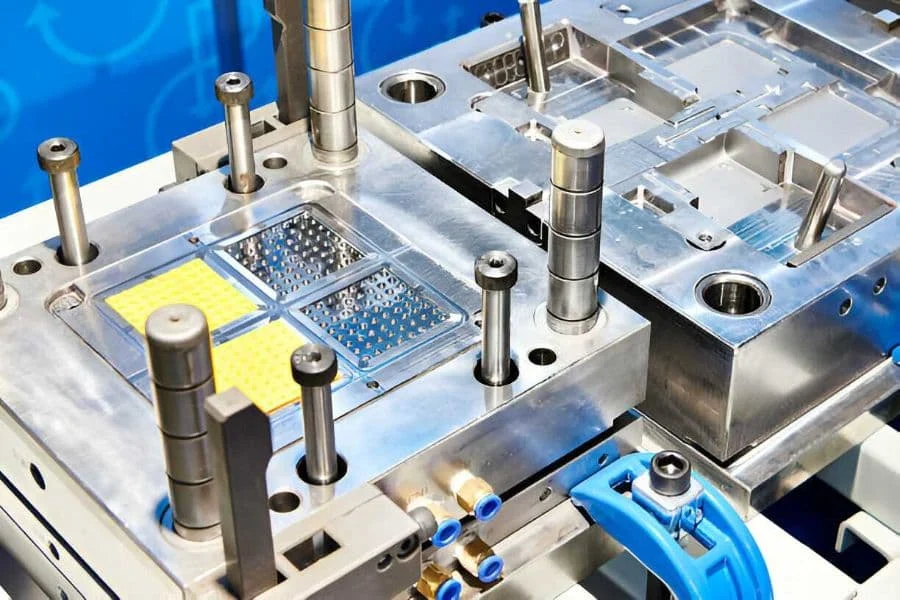

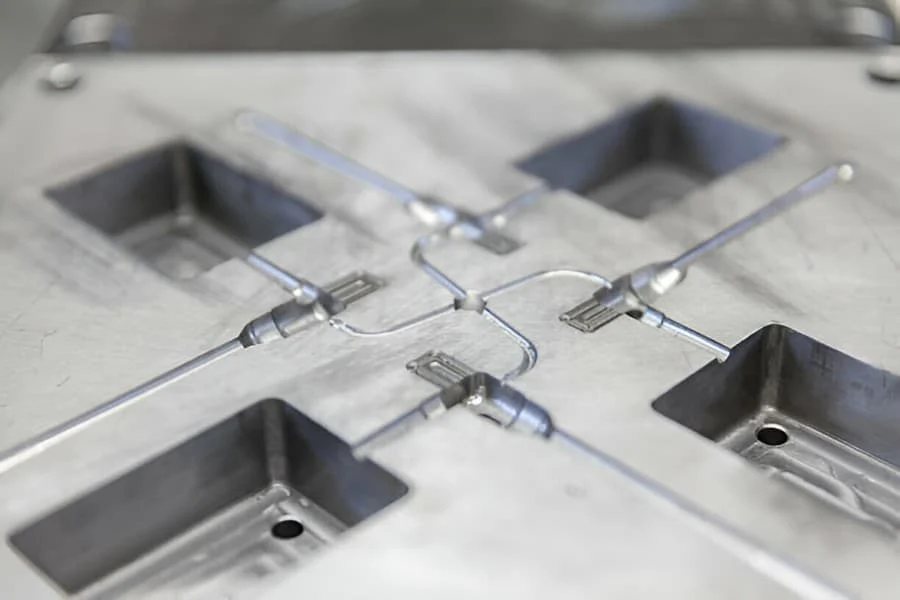

Visit our rapid tooling workshop:

Ensure rapid mold creation for your projects with the seamless integration of advanced machinery and skilled craftsmanship. Get a feel for the efficiency of our multi-cavity mold setups, which are designed for high-volume production. To streamline the tooling process, our expert team collaborates with you to select optimal materials. Embrace the simplicity of design and the cutting-edge technology of rapid tooling.

Gallery Of Rapid Tooling

Check out our display of Rapid Tooling. At EPRO, you can confidently get the best Rapid Tooling!