Laser Cutting Services

Laser cutting: what is it?

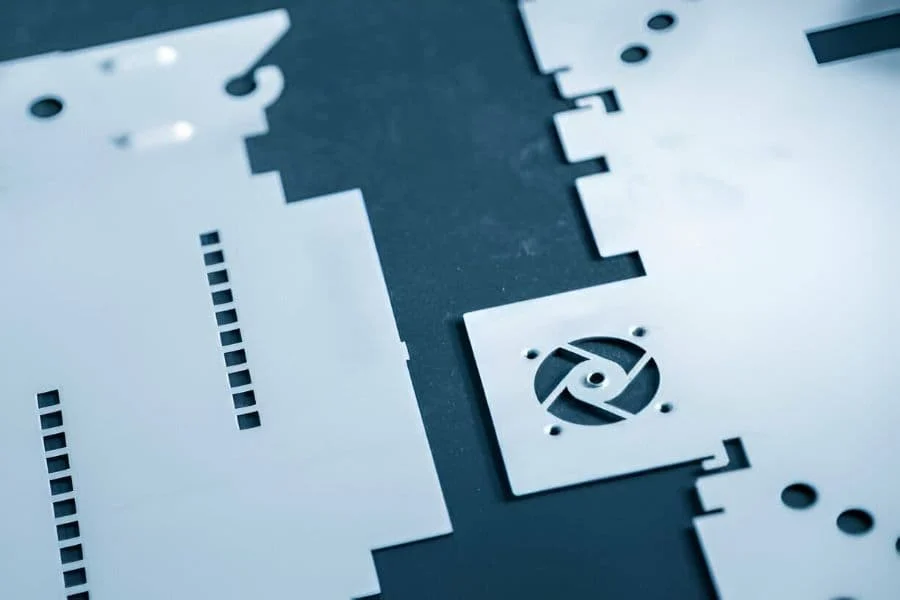

A laser beam pierces raw sheet stock to produce flat geometries through laser cutting. An industrial laser cutter uses a high-powered laser to cut materials. A laser cutter is both more precise and less energy-consuming than a plasma cutter, but there is a limitation to the thickness of the material that can be cut. Laser cutting is often used for creating intricate shapes with tight tolerances that do not require much post-processing. Other methods of cutting materials would not be efficient or practical due to their complexity.

What is the process of laser cutting?

With laser cutters, complex shapes and geometries can be cut very finely. A laser beam can be directed into a high-density light beam via the kerf width, which is only slightly larger than the laser beam. CNC machines can control laser beams or workpieces. The laser cutter blows away the material it melts, burns, vaporizes, or blows away the melted material. The cut requires little postprocessing. Laser cutting can be used on a variety of materials. High precision laser cutting allows accurate cutting of complex shapes. It is more efficient and faster as well.

Laser cutting offers several advantages

Precision Tolerances

It is possible to accommodate fine features as well as greater blank sizes with CNC controls while maintaining critical tolerances. It is ideal for industries requiring high precision and intricate designs because laser cutting guarantees precise and accurate cuts.

Finished without finishing

Using laser cutting, intricate and complex parts can be produced with high-quality edge finishes that require little post-processing. This reduces costs, increases productivity, and minimizes waste. Additionally, the finish is consistent, ensuring a reliable and repeatable outcome.

Utilize materials possibly

By cutting multiple parts from one sheet, waste can be minimized. Lasers provide superior accuracy, resulting in greater material utilization and cost savings. Moreover, laser cutting is capable of achieving tight tolerances, thereby eliminating the need for additional machining.

Cost-effectiveness

High quality and speed make it cost-competitive and valuable to our customers. As a result, prototyping and low-volume production quantities are ideal. It is also ideal for short-run production due to its lower upfront costs and shorter lead times. Furthermore, the process’ high speed and accuracy make it ideal for tight tolerance applications.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

Guidelines for laser cutting design

The following guidelines should be followed when producing flat, laser-cut parts to ensure quality and shorten production time. Additionally, make sure the part is the smallest possible size.

Maximum Size:

- Thickness 0.134 – 0.250 in.: 39 in. x 19 in.

- Thickness 0.024 in – 0.134 in.: 39 in. x 47 in.

Minimum Part Size: 0.25 in. x 0.25 in.

Material Thicknesses: 0.024 in. – 0.250 in.

Tolerances:

- +/- 0.005 in. for all features (except for hardware holes)

- +0.003/-0.000 in. on hardware insert holes to ensure correct seating of inserts

Maximum Size:

- Thickness 3.40mm – 6.35mm: 990.6mm x 482.6mm

- Thickness 0.61mm- 3.40mm: 990.6mm x 1,193.6mm

Minimum Part Size: 6.35mm x 6.35mm

Material Thicknesses: 0.61mm – 6.35mm

Tolerances:

- +/- 0.127mm for all features (except for hardware holes)

- +0.076mm/-0.000mm on hardware insert holes to ensure correct seating of inserts

Metal Laser Cutting Materials List

See below for a list of metal materials that can be laser cut by EPRO. We may also be able to quote other materials. Let us know what you need, and we’ll be happy to help.

Steel:

1075 Spring Steel, annealed/1075 Spring Steel, Blue Tempered/1095 Spring Steel, annealed/1095 Spring Steel, blue tempered/4130 chrome-moly steel, annealed/Tool Steel, annealed/Hot Rolled Steel 1045/Hot Rolled Steel A569/ASTM A1011/Steel 1008, zinc-galvanized/Steel 1018/Steel 4140, hardened/Steel A36/Steel A36, pickled and oiled/Steel A366/1008

Aluminum:

Aluminum 2024-T3/Aluminum 5052 H32/Aluminum 6061 T6/Aluminum 7075 T6/Aluminum MIC6/Pre-Anodized 6061-T6, Black

Stainless steel:

Stainless Steel 17-4 PH, annealed/Stainless Steel 301, spring temper/Stainless Steel 304/Stainless Steel 304 shim, hardened/Stainless Steel 304, #4 brushed/Stainless Steel 316/Stainless Steel 410, annealed/Stainless Steel 430, #3 brushed/Stainless Steel 440C

Other:

Brass 260/Bronze 220 H02/Copper 101, H00 to H01/Copper 110, Annealed/Nickel 625, annealed/Titanium (Grade 2)/Titanium 6Al-4V (Grade 5)

- ABS

- Acetal

- Acrylic

- Fiberglass

- Garolite G-10 (FR4), Black

- Garolite G-11 (FR5), Green

- HDPE

- Nylon 6/6, Black

- PETG Plastic

- Polycarbonate

- Polypropylene

- PTFE

- PVC

- UHMW-PE

Thicknesses for Laser Cut Parts

Learn how to choose the right thickness for laser-cut parts across a variety of materials.Manufacturing innovation is boosted with laser cutting across a range of material thicknesses, whether intricate designs or robust components.

| Image | Material | Thickness Available |

|

Aluminum | 0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

|

Steel | 0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

|

Stainless Steel | 0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

|

Copper | 0.025 in - 0.125 in. (0.635mm - 3.175) |

|

Brass | 0.025 in. - 0.125 in. (0.635mm - 3.175) |

|

Other | Click us for more details now! |

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

Laser Cutting VS Other Cutting Methods

| Material Thickness | Tolerance | KERF | Part Volume | Setup Cost | Lead Time | Notes | |

| Fiber Laser | AL: 0.250″ SS: 0.375″ CRS: 0.500″ COP: 0.250″ Brass: 0.125″ | 0.002″ – 0.005″ | .008″ | 1 to High-Volume | Low | 6-8 days | Metals – Fast |

| Omax Waterjet | Up to 6″ | 0.005″- 0.015″ | .020″/.040″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, carbon fiber, ceramics, etc. Taper up to 59 ° |

| Microcut | .0005″ – 0.5″ | 0.0005″ -0.005″ | 0.009″, 0.011″, 0.0196″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, laminates, carbon fiber, ceramics, etc. |

| Wire EDM | 0.001″ – 6″ | 0.0005″ | 0.005″ | 1-200 Is Best | Low | 6-8 days | Conductive Metals, Carbon |

| Chemical Etching | 0.005″ – 0.060″ | Is +/- 10% of material thickness, .002″ min. | Equal to metal thickness | 1- Infinity | $350 Min. | 6-8 days | Metal Only. No Burrs. Beveled Edges. Half Etch and Holes. |

Sheet Metal Prototyping Cutting Specifications and Tolerances

Our laser technology allows us to create complex shapes and intricate designs with utmost precision, making us your go-to partner.

| Material Thickness | Tolerance | KERF | Part Volume | Setup Cost | Lead Time | Notes | |

| Omax Waterjet | Up to 6″ | 0.005″- 0.015″ | .020″/.040″ | 1 to 5,000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, Kevlar, carbon fiber, ceramics, etc. Taper up to 59° |

| Microcut | .0005″ – 0.5″ | 0.0005″ - 0.005″ | 0.009″, 0.011″, 0.0196″ | 1 to 5,000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, Kevlar, laminates, carbon fiber, ceramics, etc. |

| Fiber Laser | AL: 0.250″ SS: 0.375″ CRS: 0.500″ COP: 0.250″ Brass: 0.125″ | 0.002″ – 0.005″ | .008″ | 1 to High-Volume | Low | 6-8 days | Metals - Fast |

| Wire EDM | 0.001″ – 6″ | 0.0005″ | 0.005″ | 1-200 Is Best | Low | 6-8 days | Conductive Metals, Carbon |

| Chem Etch | 0.005″ – 0.060″ | Is +/- 10% of material thickness, .002″ min. | Equal to metal thickness | 1 - Infinity | $350 Min. | 6-8 days | Metal Only. No Burrs. Beveled Edges. Half Etch and Holes. |

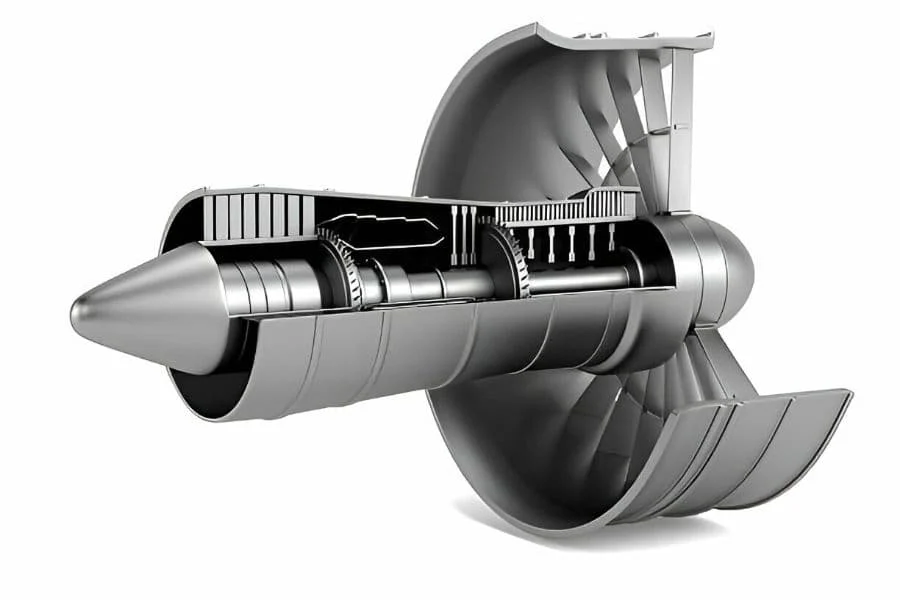

Laser Cutting for Variety of Applications

Many industries use laser cutting, including energy storage, computer electronics, robotics, and aerospace. A laser cutter can also create intricate shapes and patterns in materials such as glass, plastic, and metal. This method is also highly efficient and accurate, making it ideal for a wide variety of industrial uses.

Laser Cutting Aerospace Parts Include:

Cabin Parts

Wing Ribs

Fuselage Components

Actuators

Motion Controls

Engine Housings

Landing Gear Components

Discs

Filter Bodies

Laser Cutting Automotive Parts Include:

Lighting

Engines

Cylinder Heads

Gearboxes

Interior Panels

Drive Axles

Interior Panels

Starter Motors

One-off Custom Components for Rare

See Laser Cutting Medical Parts Include:

Hip Replacements and Knee Implants

Surgical Tool Production

Electronic Medical Equipment

Custom Prosthetics

Small Orthopedic Hardware

Medical Device Prototypes

Dental Tools and Implants

Implant Holders

Biopsy Tubes

Precision-machined Robotics and automation Parts Include:

Robotic Arm

End Effectors

Custom Jigs and Fixtures

Sensors and Controllers

Structural Components

Gears

Modular Tooling

Robotic System Motor Components

End of Arm Tooling

Cutting Laser Parts: Tips and Tricks

In tight-fitting assemblies and interlocking components, kerf compensation may be necessary to account for the material removed by the laser beam. The dimensions should be adjusted as needed for a precise fit. Finally, you should consult with our team of experts about the project requirements, material options, and design considerations. Make the most of our industry knowledge and experience to optimize your laser cutting process for exceptional precision and quality.

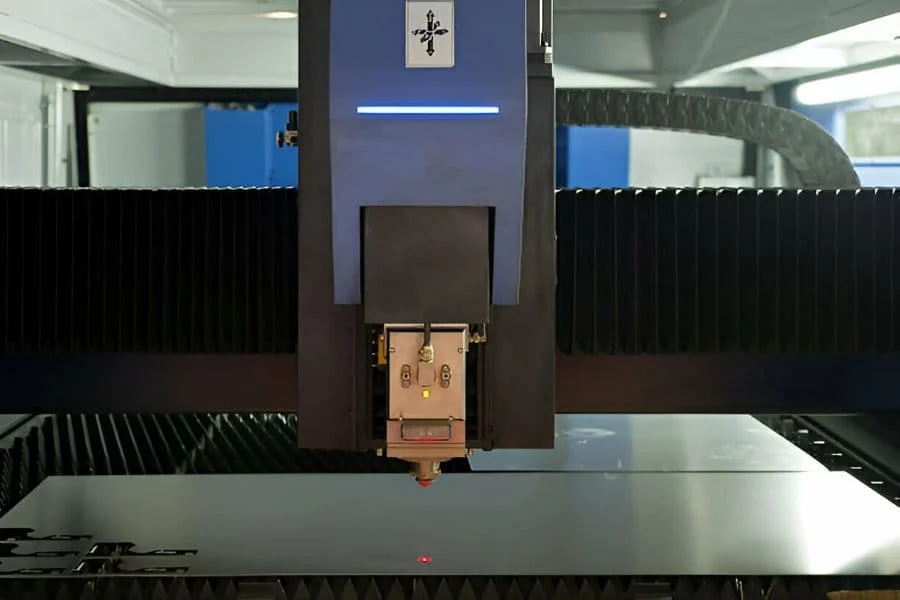

Tour Our Laser cutting Machine Shop

Using our state-of-the-art laser cutting workshop, we will shape the future of manufacturing with precision and innovation. Explore our cutting-edge laser cutting facility and advanced technology in our virtual tour. For our customers, our experts are always pushing the boundaries of what is possible. Creating innovative solutions that exceed expectations is our company’s goal. If you have any questions, please do not hesitate to contact us.

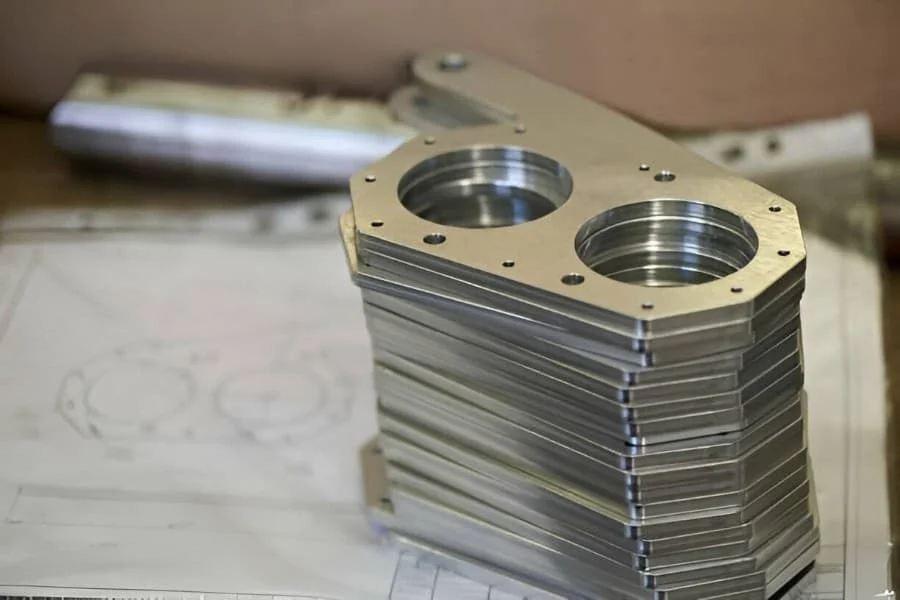

Gallery Of Laser Cutting Parts

Check out our display of Sheet Metal Parts. At EPRO, you can confidently get the best Sheet Metal parts!