Vacuum Casting Service at EPRO-RAPID

Vacuum Casting: What Is It?

Casting parts with vacuum pressure, also referred to as urethane casting or polyurethane casting, is a process that produces production-quality parts without the high expense or long lead time associated with production tooling. Vacuum casting uses a negative mold fabricated from a 3D CAD model. Injection of molten material into the mold is followed by cooling and solidification. After the part has been released from the mold, the mold is opened.

Instead of using metal injection moulds (steel, aluminum, etc.) vacuum casting uses soft silicone moulds. Injection molding is often used in the early stages of product development before creating small batches of parts with this process. The vacuum casting process is an efficient and cost-effective method for rapidly producing small quantities of parts.

Injection molding: why choose EPRO?

Exceptional surface finish

In industries that value aesthetics, the process is ideal for adding colours and finishes. As a result, unique and custom pieces can also be created using different materials and finishes. Additionally, the process produces less waste and emissions, making it eco-friendly.

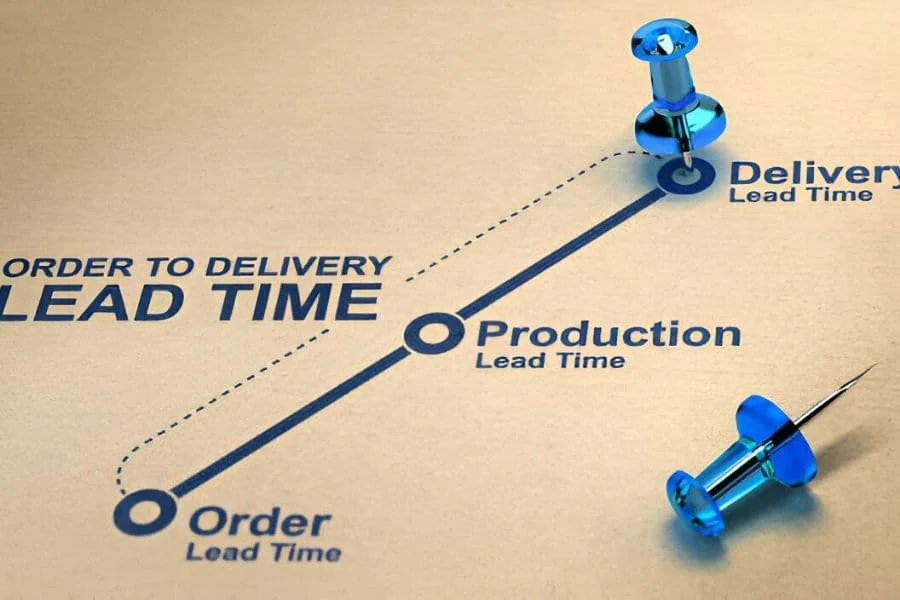

Faster lead times

Steel and aluminium moulds take weeks to make, while silicone moulds take days. Producing products faster and saving on production costs is possible. Furthermore, silicone moulds can be recycled and reused.

A lower up-front cost

Vacuum casting requires less upfront investment than injection moulding. For small-batch production, tooling costs aren’t amortized. Small batches can also be produced much faster with vacuum casting than injection molding.

Large Components

Join large parts without joining them together. Casting 2m parts is easy at EPRO. Casting 2m parts in a single build eliminates the need for multiple components to be joined together, making large-sized parts more efficient and seamless to produce.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

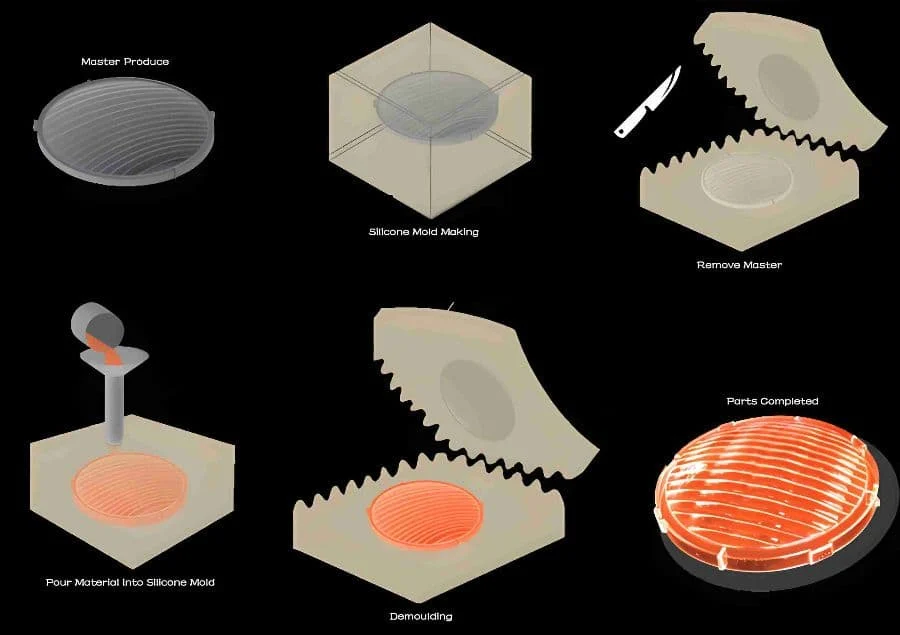

Vacuum casting: how does it work?

Building the master model,Creating the silicone tool and producing the parts are the three main stages.

Building a master model

For dimensional accuracy, a master model must be high-quality. To achieve the desired surface texture and quality, the master model is typically made via 3D printing or CNC machining. The final vacuum casted part will replicate every tiny detail, so creating a flawless master model is critical.

Creating the silicone mould tool

Once the master model is suspended, liquid silicone is poured around it in a casting box. In a casting box maintained at 40°C for approximately 8-16 hours, silicone molten cures. A hollow space is left in the middle of the silicone mould after the mould has solidified and cured, which fits the master model’s dimensions and specifications.

Producing the parts

A funnel is used to fill the ‘hollow’ mould with polyurethane (PU) uniformly and without air bubbles. In casting machines, molds are sealed and cured at 70°C. After cooling, the shaped material is removed from the mold. Repeat 10 to 20 times. It gradually loses its shape at these limits, affecting dimensional accuracy.

What options for the vacuum casting we can make?

Vacuum casting materials are becoming more diverse with the development of molecular and material science. The three major vacuum casting materials are thermoplastics, rubbers, and resins, which can emulate specific properties and characteristics such as:

- Physical appearance quality.

- Surface texture/finish.

- Transparency/translucence

- Rigidity.

- Flexibility.

- Strength.

- Hardness.

- Temperature resistance.

- UV stability.

- Color.

Vacuum Casting Materials

Vacuum casting materials can be selected based on the particulars of your project. To help you make the right decision, we have grouped our urethane casting materials by general categories. Vacuum casting materials are specially formulated for precise, detailed, and durable parts. Color options are also available, allowing you to customize your parts.

ABS-like

Versatile polyurethane plastic resin that is analogous to ABS thermoplastic. Hard, rigid, and impact resistant, it is ideal for various products.

Price: $$

Colors: All colors; precise pantone color matching available

Hardness: Shore D 78-82

Applications: General purpose items, enclosures

Acrylic-like

Stiff, transparent urethane resin simulating acrylic. It is hard, with medium to high strength and good clarity for see-through products.

Price: $$

Colors: Clear/RAL/Pantone colors

Hardness: Shore D 87-99

Applications: Light pipes, see-through components, signal display, partition material

Polypropylene-Like

Tough, flexible, and abrasion-resistant urethane with low cost and polypropylene-like ductility.

Price: $$

Colors: Black or natural only

Hardness: Shore D 65-75

Applications: Enclosures, food containers, medical applications, toys

Polycarbonate-Like

Rigid, high-impact, and clear material with a wide variety of uses. Easy to machine and finish, simulating polycarbonate.

Price: $$

Colors: Clear and various colors

Hardness: Shore D 82-86

Applications: Light diffusers, signs, skylights, visors

Elastomer

Polyurethane plastic resin, simulating rubber-like materials like TPU, TPE and silicone rubber.

Price: $$

Colors: All colors and precise Pantone color matchings

Hardness: Shore A 20 to 90

Applications: Wearables, overmolds, gaskets

Vacuum Casting Technical Guide

EPRO offers a range of vacuum casting tolerances to meet your custom requirements.We can also achieve tolerances up to 0.1 mm for complex parts. Our vacuum casting process provides reliable and accurate results, ensuring your parts are of the highest quality.Below are the technical specifications for our vacuum casting services.

| Type | Information |

| Standard accuracy | Standard tolerance on ±0.15mm/100mm, with the highest precision able to reach ±0.05 mm. |

| Maximum part dimensions | The vacuum equipment can hold 2.0M*1.2M*1.0M mold specifications. |

| Minimum wall thickness | The minimum wall thickness is 0.5mm, the best is 1.5mm~2.5mm to ensure the mold is filled properly. |

| Lifetime of the silicone mold | Typical quantities up to 20-25 copies per mold. If the part requires high quality such as clear or complex structures, in typical quantities one mold can only make 12 or even 10 casting parts. |

| Color & Finishing | Color and texture can be customized |

| Typical Lead Time | Up to 20 parts in 15 days or less |

Vacuum Casting Part Surface Finishes

EPRO offers an extensive array of surface finishes for vacuum casting parts. Plastic, metal, and ceramic materials can all be treated with these surface finishes. In addition, EPRO can customize your parts with a variety of colors, textures, and patterns. These finishes help meet your products’ appearance, hardness, and chemical resistance requirements. Depending on the material selection and application of your part, we can offer the following surface finishes:

High Gloss

Description

Highly reflective surface finish created by polishing the master pattern before mold making. The high-gloss finish offers high transparency useful for cosmetic parts, lenses, and other cleanable surfaces.

SPI Standard

A1, A2, A3

Semi Gloss

Description

This B grade finish is not highly reflective but offers some sheen. Using gritty sandpaper, you will get smooth, cleanable surfaces between high-gloss and matte.

SPI Standard

B1, B2, B3

Matte Finish

Description

Vacuum cast parts will have a satin-like finish through the bead or sand blasting of the master pattern. The C-grade finishes are ideal for high-touch areas and handheld components.

SPI Standard

C1, C2, C3

Custom

Description

EPRO can also provide custom finishes through additional processes. On request, you can get unique secondary finishes for the best results.

SPI Standard

D1, D2, D3

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

Plastic injection molding applications

The plastic injection molding process has numerous applications across a wide range of industries. With its precision and efficiency, it is indispensable for automotive components, medical devices, consumer electronics, and more. In diverse sectors, this technology delivers high-quality and customized plastic products for a variety of industrial uses.

Vacuum Casting Tips

You should choose the right casting materials based on factors such as strength, durability, and flexibility for your specific application. Ensure uniform wall thickness and minimize intricate details for consistent casting results. Work closely with our experienced team to optimize mold design and casting parameters to maximize efficiency and quality. Maintain stringent quality control measures to ensure precise dimensions and high-quality products.Contact our professionals today.

Come to see our vacuum casting workshop

Take a tour of our cutting-edge vacuum casting workshop and see innovation at work. Discover how we integrate advanced machinery with expert craftsmanship to produce high-quality prototypes and production parts. Each step in the process is meticulously executed for superior quality and precision, from custom molds to intricate details. Discover first-hand why our vacuum casting services are the epitome of excellence.

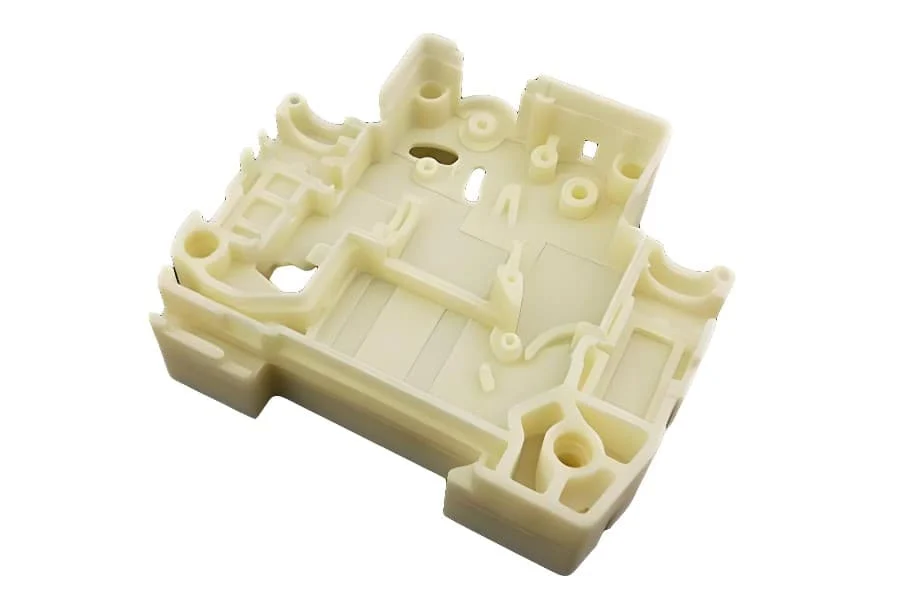

Gallery Of Vacumm Casting Parts

Check out our display of Vacumm Casting Parts. At EPRO, you can confidently get the best Vacumm Casting parts!