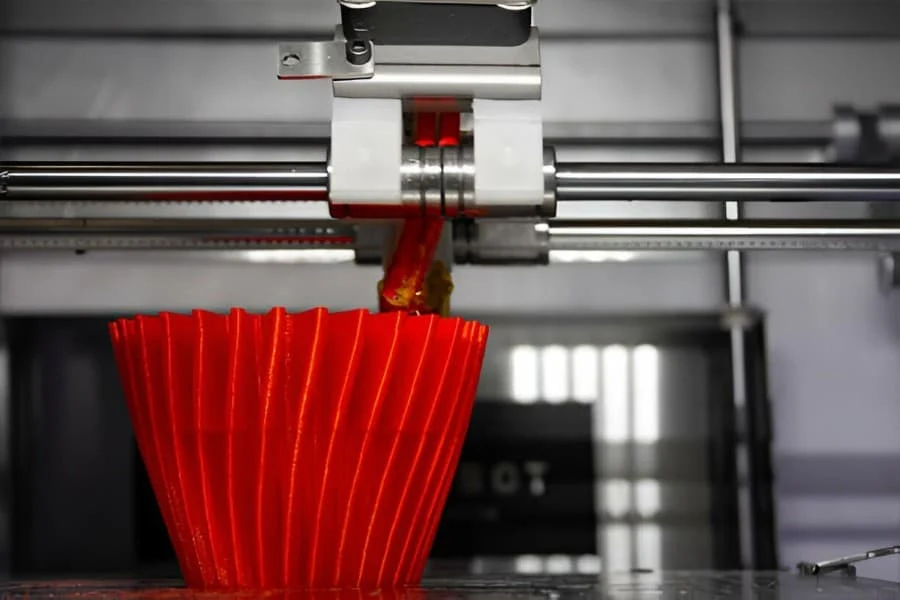

SLA (Stereolithography)

Stereolithography (SLA) – what is it?

A photosensitive liquid is hardened using an ultraviolet laser, creating a layer-by-layer 3D model. Originally developed for manufacturing processes, stereolithography, or SLA, allows you to produce high-quality, detailed prototypes of your product.It also offers smoother surface finishes and tighter tolerances, which are beneficial during the fitting phase of your product assembly process. A significant part of the development of a product relies on the efficiency and reliability of SLA technology.

Advantages of EPRO'S Stereolithography(SLA)

Finished surfaces of high quality

SLA parts offer excellent surface finish and dimensional accuracy when testing prototype parts. An SLA part is smooth and precise since a liquid resin solidifies layer by layer.

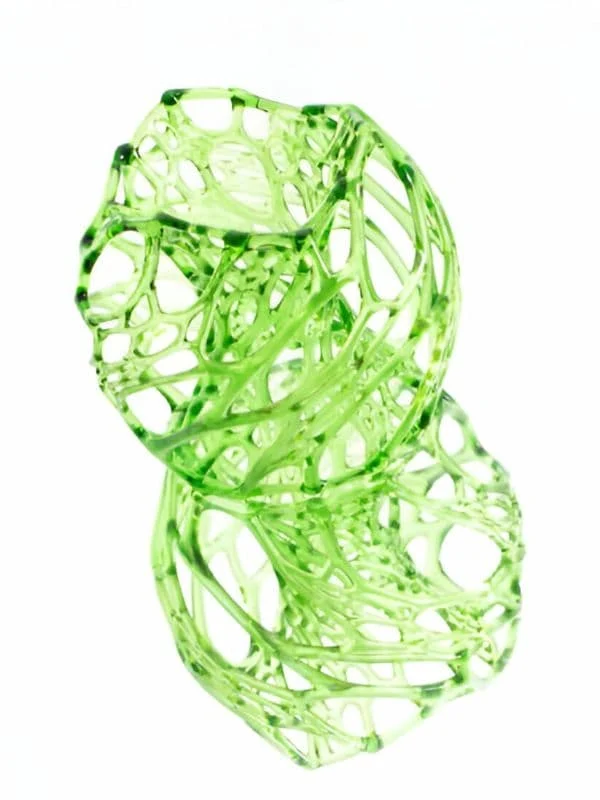

Parts in clear

A clear resin can be used for SLA parts and then sanded to a glass-like finish after they have been printed. Clear SLA parts serve a variety of applications, including optics, lighting fixtures, and transparent prototypes.

Small Layer Size

With SLA, layers can be as thin as 0.002 inches. This results in surfaces with fine details and cosmetic appeal. Precision and intricate designs can be achieved with SLA parts.

Complex shapes can be printed

Due to its fine resolution (hundreds of microns), SLA can be used to print thin walls, sharp corners, small holes, and complex shapes.

Tolerances

SLA has the tightest dimensional tolerances of any additive manufacturing method. With SLA, intricate and detailed designs can be manufactured with tolerances below 0.1mm.

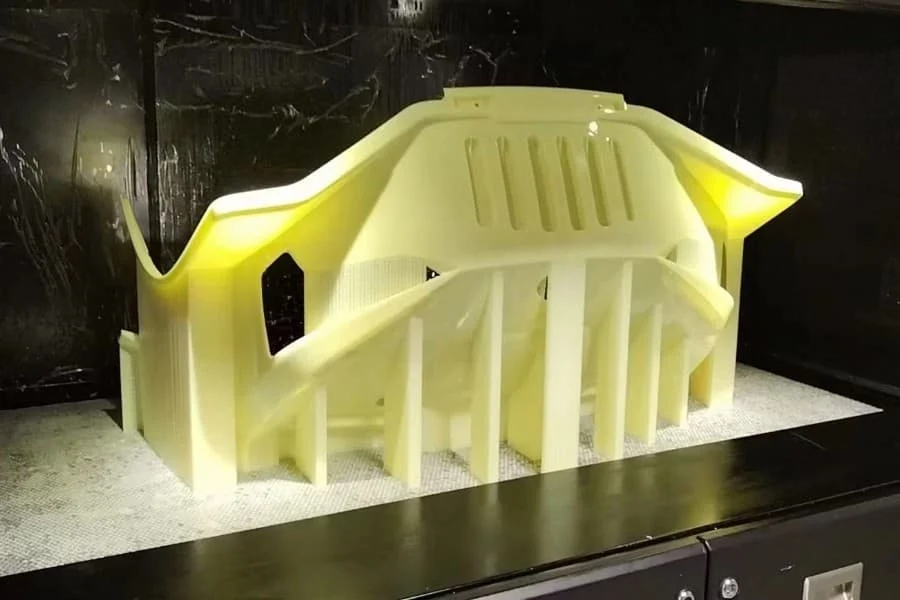

Prototypes that are larger

SLA can produce large, lightweight prototype parts using a lattice structure. A SLA prototype can have internal lattice structures, allowing lightweight designs with structural integrity. This makes SLA an ideal method for producing larger prototypes.

Post-processing-friendly

Postprocessing methods such as sanding, painting, and clear coating are ideal for SLA parts. It is easy to refine and customize SLA prints due to their high level of detail.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

SLA Material Options

Our range of thermoplastic and thermoset materials includes over 100 different types of materials. Their durability, cost-effectiveness, and suitability for a wide range of applications make them ideal for a variety of applications. If you’re looking for alternative material options, check out our guide to resin substitutes for ABS, PC, PP, and other commonly molded plastics.

- ABS-Like White(Accura Xtreme White 200)

- ABS-Like Gray(Accura Xtreme Gray)

- ABS-Like Black(Accura 7820)

- ABS-Like Translucent/Clear (WaterShed XC 11122)

- PP-Like Translucent White (Somos 9120)

- PC-Like Translucent/Clear (Accura 60)

- PC-Like Advanced High Temp* (Accura 5530)

- Ceramic-Like Advanced HighTemp*(PerFORM)

- True Silicone

SLA Part Surface Finish Options

Our wide range of high-quality materials enables stereolithography (SLA) to be used in a wide range of applications. We offer a variety of options to meet your project requirements, from standard resins to engineering-grade options. Discover how our SLA process achieves extraordinary precision and surface finish.

Description of Custom Surface Finishes

Custom finishing is a mix of science, technology, and fine art that can transform a part to your exact specifications. Finishes include:

- Soft-touch paint

- Clear part finishing

- Paint finishes

- Masking

- Color matching

- Decals/graphic

- Texture

- Metal Plating

- Microfluidics

Description of Unfinished

Dots, or standing”nibs,” remain evident on the bottom of the part from the support structure remnants. Good for when fast lead times are required or cost is a factor

Description of Natural Surface Finish

Supported surfaces are sanded down to eliminate the support nibs.

Description of Standard Surface Finishes

Supported surfaces are sanded, and the entire part is finely blasted for a consistent look. Note that the layers are still present.

SLA Design Guidelines and Capabilities

Our basic guidelines for stereolithography include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

| Max Part Size | Layer Thickness | Min Feature Size | Min Wall Thickness | Min Hole Size | |

| Normal Resolution | 736mm x 635mm x 533mm | 0.1016mm | X-Y: 0.254mm Z: 0.406mm | 0.254mm | 0.635mm |

| High Resolution | 254mm x 254mm x 254mm | 0.0508mm | X-Y: 0.1016mm Z: 0.406mm | 0.1016mm | 0.508mm |

| Micro Resolution | 127mm x 127mm x 63.5mm | 0.0254mm | X-Y: 0.0635mm Z: 0.203mm | 0.0635mm | 0.381mm |

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

Stereolithography (SLA) applications

A broad range of industries are impacted by SLA’s revolution in product development. Healthcare can create precise prototypes and customized implants with it. Automotive components benefit from rapid prototyping. Consumer electronics companies are embracing SLA for its sleek, intricate casings. Aerospace can use lightweight and intricate components made with this technology. Various industries benefit from SLA’s innovations.

SLA has the following benefits over SLS:

The main mode

- Compared to other types of 3D printing, SLA 3D printing has a smooth surface, good dimensional stability, and fine features that make it suitable for the reproduction of prototype master molds. In 3D printing, stereolithography, or SLA, is the primary method for creating prototype master molds since it produces high-quality parts with superior surface finish and precise details.

Accuracy of dimensions

- Minimum wall thickness for SLA 3D printing is 0.02 inches (0.5 mm); tolerance is 0.006″ (0.15mm) to 0.002″ (0.05mm). The minimum wall thickness for SLS 3D printing is 0.04″ (1.0mm); the tolerance is 0.008″ (0.20mm) to 0.004″ (0.10mm). The SLA technology allows for finer laser beam diameters and high-resolution slices, resulting in finer details and more accurate final prints than SLS. In SLA 3D printing, the laser beam diameter can be reduced and the layers built in a higher resolution to ensure greater detail and accuracy.

Stereolithography (SLA) Parts Tips

The SLA process produces parts that are highly accurate to CAD and are capable of producing complicated shapes and geometries.With SLA, thick and thin sections can be printed without problems, but walls and other features should be at least 0.4mm wide and high due to the printer’s resolution. The SLA printer can also produce complex shapes with intricate details, but it needs to be designed correctly. When designing parts, the printer’s resolution should also be considered.

Our Stereolithography (SLA) workshop is open for tours

We are proud to welcome you to our state-of-the-art Stereolithography (SLA) workshop. The seamless integration of high-performance SLA machines and advanced software ensures unparalleled accuracy and speed in prototyping. In order to ensure each project meets the highest standards, our technicians oversee the process meticulously. It’s time to experience a dynamic environment filled with resin tanks, UV curing stations, and intricately designed prototypes that are taking shape as you explore.

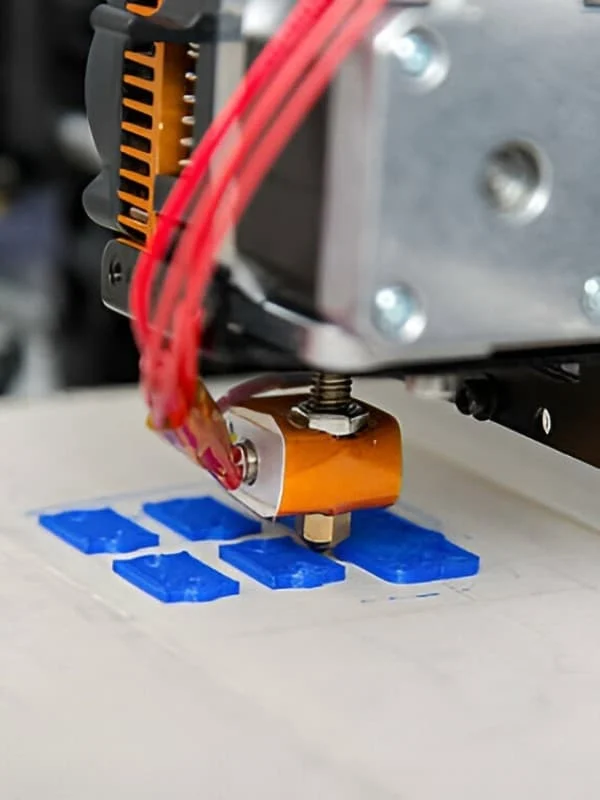

Gallery Of Stereolithography (SLA) Parts

Check out our display of SLA Parts. At EPRO, you can confidently get the best SLA parts!