Sheet metal Fabrication Service

Sheet metal: how does it work?

We offer a variety of sheet metal services, including bending, shearing, staking, and stamping. It is common to use these parts for drilling, tapping, counterboring, and countersinking. There is no limit to what sheet metal parts can be used for, from simple prototypes of bent sheet metal to the production of complex, multi-part assemblies. In addition to being cost-effective and durable, sheet metal parts can be manufactured to a precise tolerance. Additionally, they are highly recyclable, making them a good choice for a wide range of applications.

Our Sheet Metal Services

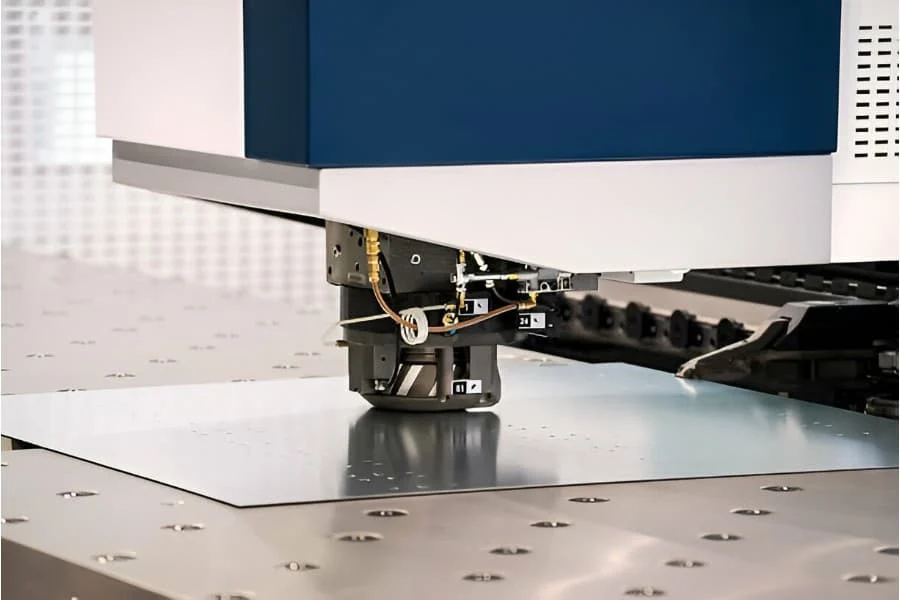

We manufacture sheet metal parts by laser cutting, water jetting, or chemically etching blanks.For prototypes and large production runs, we have state-of-the-art facilities. You can rely on our sheet metal services to meet your production needs.

Blanking

These machines cut metal, plastic, and other materials into desired shapes by using lasers, plasmas, CNC turrets, and waterjets. Precision and efficiency make them ideal for creating complex shapes quickly and efficiently.

Bending

Tools for stamping, dies for press brakes. Bending is a manufacturing process for deforming materials into desired shapes. In order to bend materials, press brakes and dies can be used. Making repeated impressions on materials is done with stamping tools.

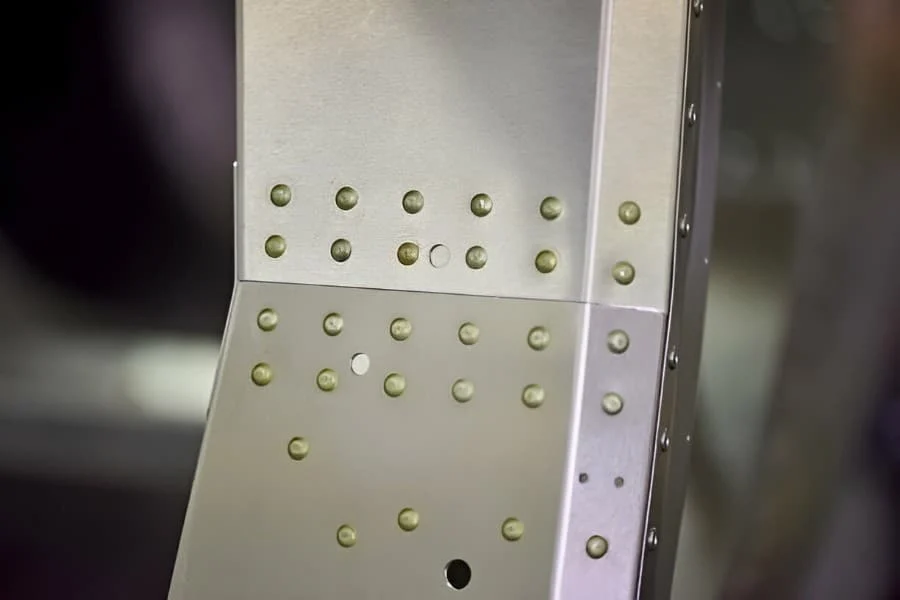

Insert installation information

We offer a full catalog of PEM inserts and fasteners, both metric and standard. For PEM inserts and fasteners, we offer a wide variety of sizes and materials. Temperatures and pressures are not a problem for our products. We provide a lifetime guarantee on our inserts, which are easy to install.

Finishing secondary to primary

Powder coating, anodizing, plating, and painting. Metal or alloy products can be enhanced with secondary finishing processes. Using these processes improves the durability of the product, increases corrosion resistance, and provides an attractive finish.

Why Choose EPRO's Sheet Metal?

Projects of Varying Scope

From simple bent sheet prototypes to multi-part electro-mechanical assemblies, EPRO offers sheet metal services. Our experts use the latest technology to produce precise results. We provide comprehensive support throughout the project.

Material With Flexibility

It is possible to cut, bend, and stretch metal sheets to achieve virtually any shape you desire. This makes it suitable for prototyping and mass production. It can be used in a wide variety of applications because of its light weight and low cost.

Long-lasting And Strong

It is stronger and more durable than plastic, able to withstand higher temperatures and pressures. Their corrosion and oxidation resistance makes them suitable for many environments. It’s easy to carry and transport sheet metal parts because they’re lightweight.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

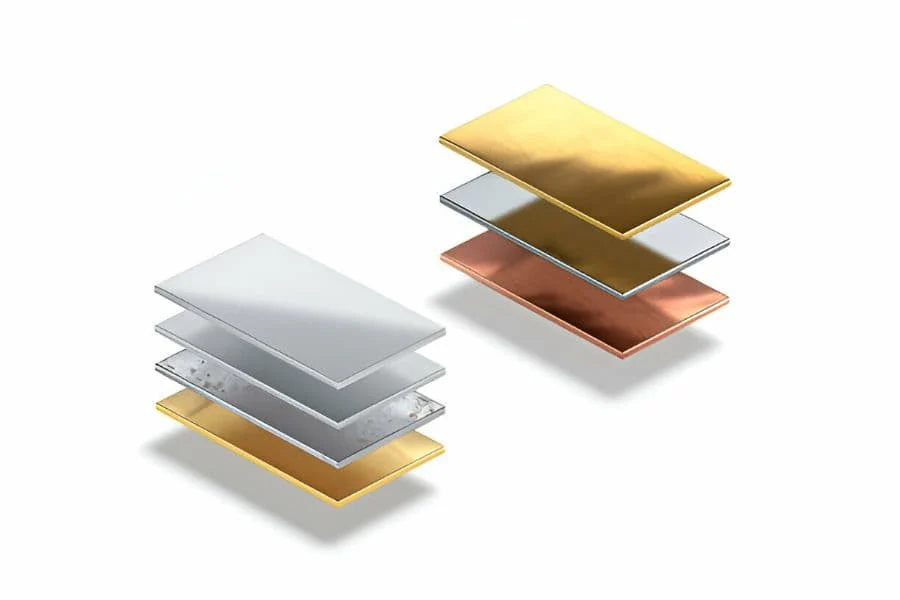

Sheet Metal Fabrications Materials

Using our Sheet Metal Fabrication Materials, you can achieve precision.With these carefully chosen materials, you can be assured of superior performance, durability, and precision.

Aluminum

Lightweight and corrosion-resistant, aluminum is ideal for sheet metal fabrications requiring strength and durability, such as aircraft components and automotive body panels.

- 5052-H32 Aluminum

- 6061 Aluminum

- 7075 Aluminum

Copper

Known for its excellent electrical conductivity, copper is often used in sheet metal fabrications for electrical components, heat exchangers, and decorative elements due to its malleability and aesthetic appeal.

- Copper 101

- Copper C110

- Copper C110, H02

- Copper 260 (Brass)

Bronze

With its high strength, wear resistance, and thermal conductivity, bronze finds application in sheet metal fabrications for bearings, gears, marine hardware, and sculptures, where durability and aesthetic appeal are paramount.

- Bronze 220

- Bronze 510

Stainless Steel

Renowned for its corrosion resistance and strength, stainless steel is a versatile material in sheet metal fabrications for various industries, including aerospace, automotive, medical, and architecture, where hygiene, durability, and aesthetic appearance are critical.

- Stainless steel 301

- Stainless steel 304

- Stainless Steel 304 #4 brushed

- Stainless Steel 304, #8 mirror polish

- Stainless steel 316/316L

- Stainless Steel 316, #4 brushed

Steel

Offering excellent strength, machinability, and weldability, steel is widely used in sheet metal fabrications for structural components, automotive parts, machinery, and appliances, where durability and cost-effectiveness are essential.

- Steel 1018 (Low Carbon)

- Steel 1045 (Hot Rolled)

- Steel A569/ASTM A1011 (Hot Rolled)

- AZ55 Galvalume

- A653 Galvanized

- 1095 Spring Steel

- Steel A36

- Steel A36, pickled and oiled

- Steel A366/1008

Nickel Alloys

Known for their exceptional heat and corrosion resistance, nickel alloys are preferred in sheet metal fabrications for aerospace, chemical processing, and marine applications where resistance to extreme temperatures and harsh environments is required.

- Inconel 625

- Nickel Alloy 200

- Nickel Alloy 400

Titanium

Recognized for its high strength-to-weight ratio and corrosion resistance, titanium is used in sheet metal fabrications for aerospace components, medical implants, and sporting goods, where lightweight yet durable materials are essential for performance and longevity.

- Titanium (Grade 2)

- Titanium 6AI-4V (Grade 5)

Tolerances and Specifications for Sheet Metal Fabrications

With sheet metal cutting services, precision levels up to 0.0005″ are possible. Complexity, geometry, and raw materials also affect tolerance.

| Material Thickness | Tolerance | Kerf | Part Volume | Set Up Cost | Lead Time | Notes | |

| OMAX WATERJET | Up to 6″ | 0.005″- 0.015″ | .020″/.040″ | 1 to 5,000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, Kevlar, carbon fiber, ceramics, etc. Taper up to 59° |

| MICROCUT™ | .0005″ – 0.5″ | 0.0005″ - 0.005″ | 0.009″, 0.011″, 0.0196″ | 1 to 5,000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, Kevlar, laminates, carbon fiber, ceramics, etc. |

| FIBER LASER | AL: 0.250″ SS: 0.375″ CRS: 0.500″ COP: 0.250″ Brass: 0.125″ | 0.002″ – 0.005″ | .008″ | 1 to High-Volume | Low | 6-8 days | Metals - Fast |

| WIRE EDM | 0.001″ – 6″ | 0.0005″ | 0.005″ | 1-200 Is Best | Low | 6-8 days | Conductive Metals, Carbon |

| * CHEM ETCH | 0.005″ – 0.060″ | Is +/- 10% of material thickness, .002″ min. | Equal to metal thickness | 1 - Infinity | $350 Min. | 6-8 days | Metal Only. No Burrs. Beveled Edges. Half Etch and Holes. |

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

Here are some tips for sheet metal parts

It’s versatile and economical to use sheet metal parts in products. There are several methods for manufacturing sheet metal parts and assemblies. Considering each method is different. Besides bending, punching, cutting, welding, and forming, sheet metal parts can be shaped into many shapes. Part finishes, coatings, and treatments can also be customized.

For more information, contact our rapid manufacturing team.

Sheet Metal Fabrications for Various Industrial Applications

Discover how sheet metal fabrications are used across diverse industrial sectors. Aerospace, automotive, construction, electronics, and many other industries use sheet metal components. With fabrication services tailored to the rigors of modern manufacturing, we provide solutions for intricate brackets and structural panels.

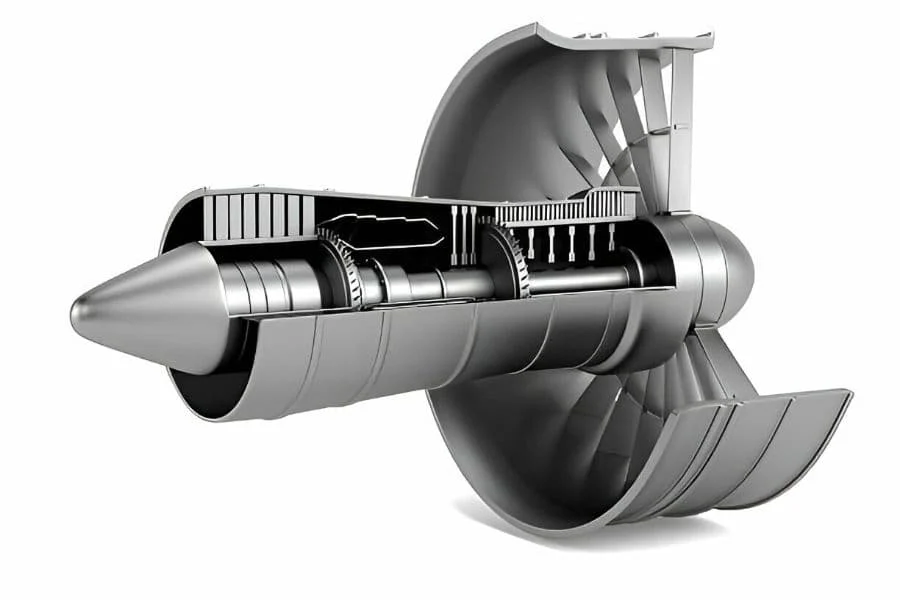

Aerospace & Defense

It is important to fabricate sheet metal with precision for aerospace and defense projects. Whether it is aircraft components or military hardware, our expertise ensures that each piece meets the highest standards of durability, reliability, and performance, essential for demanding applications.

Automotive

With our sheet metal fabrications, you can revolutionize your automotive designs. A variety of lightweight, yet robust components are produced using our advanced fabrication techniques, which meet the stringent requirements of the automotive industry, from chassis components to body panels.Let’s call EPRO Today!

Medical

Our sheet metal fabrications are trusted for critical medical equipment and devices. The precision manufacturing capabilities of our facility ensure compliance with strict regulatory standards while maintaining the highest levels of hygiene and sterilizability for intricate parts such as enclosures, trays, and surgical instruments.

Robotics and Automation

We provide precision sheet metal fabrications for robotics and automation systems. Our robotic and automated components, including structural frames, enclosures, and brackets, are designed for seamless integration and optimal functionality.Let’s call EPRO Today!

Consumer Products

With our versatile sheet metal fabrications, you can enhance your consumer products. We provide high-quality, aesthetically pleasing parts that meet consumer demands for durability, functionality, and modern design in electronic enclosures and household appliances.

More Industries

Design services

New energy

Electronics & Semiconductor

Education

Industrial Machinery & Equipment

Supply Chain and Purchasing

Tour Our Sheet Metal Shop

Check out our incredible line of well-functioning Sheet Metal machining centers ranging from the best Sheet Metal horizontal machining center to top-notch vertical machining centers. These are ideal facilities for manufacturing components for various industries. We combine advanced technologies with skilled technicians to deliver results to suit your needs perfectly.

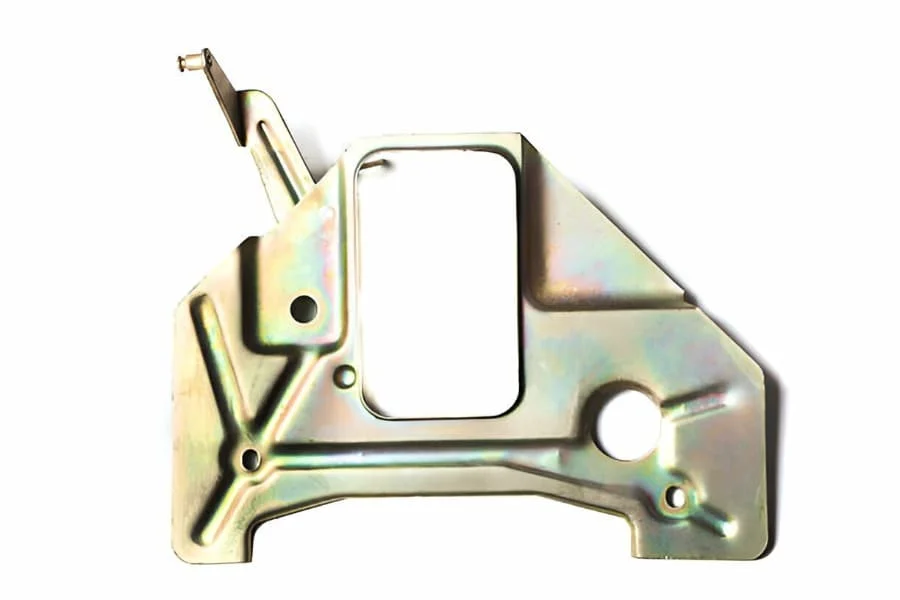

Gallery Of Sheet Metal Parts

We display a wide range of sheet metal parts. We offer the best Sheet Metal parts at EPRO! All sizes and shapes are available, making them perfect for any project. In addition to being high-quality and durable, our parts are made using the latest technology. You can rest assured that all of our orders will be fulfilled to your satisfaction!