OEM Metal Extrusion Services

Metal Extrusion: What Is It?

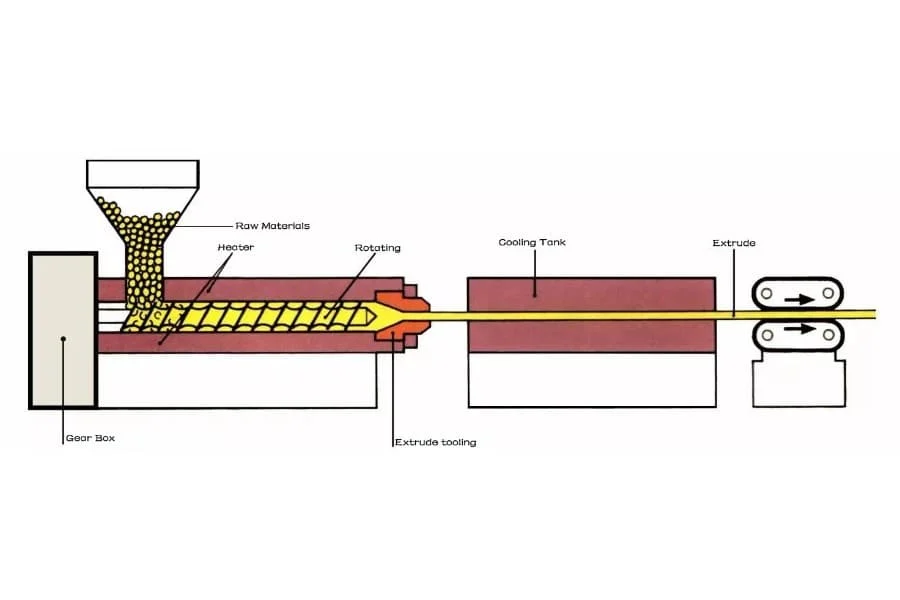

Metal extrusion involves forcing a workpiece of a certain length and cross section through a die of a smaller cross section, thereby forming the work to a new cross section. By using this method, a variety of cross sections can be manufactured.Material content and profile will determine the length of the extruded part. As a result, the cross section of the metal extrusion will be uniform along its entire length. As a starting point, a round billet is usually formed into a round part of a smaller diameter, a hollow tube, or another profile.Extrusion can also be used to produce parts with accurate dimensions and smooth surfaces.

Whenever a constant cross-section material is required in high volumes, metal extrusion is the best process. Extrusions can also be used to create complex shapes, making them ideal for a wide range of industrial uses. Also, extrusion is cost-efficient and energy-efficient.

Advantage of metal extrusion

- A metal extrusion part can have a very complex cross-section that stays fixed throughout. Extrusion allows greater precision and accuracy in component design, since further machining is not required after extrusion. The process of metal extrusion can also produce complex shapes at a cost-effective rate.

- Aluminum and steel parts with very thin walls are possible. Parts with a lot of detail or complex shapes benefit from this. In addition, the parts are lightweight and strong, making them useful in many applications.

- Metal extrusion only subjected to compressive and shear stresses. It is therefore possible to create extrudates from very brittle materials. Furthermore, complex shapes can be created with tight tolerances using the process. As a result, it’s a great choice for automotive, construction, and aerospace applications.

- Surface finish is excellent, unlike similar metal forming processes. In addition, the process is cost-effective, as there is no need for expensive tooling or heavy machinery. High-quality parts with complex geometries can be produced, making it an ideal choice for many applications.

- The processed parts have an elongated grain structure. The structure improves parts’ toughness and strength. It is also non-polluting and uses no hazardous materials, making it environmentally friendly.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

Types of Metal Extrusion Processes

Various types of metal extrusion processes are used today, each with its own set of qualities:

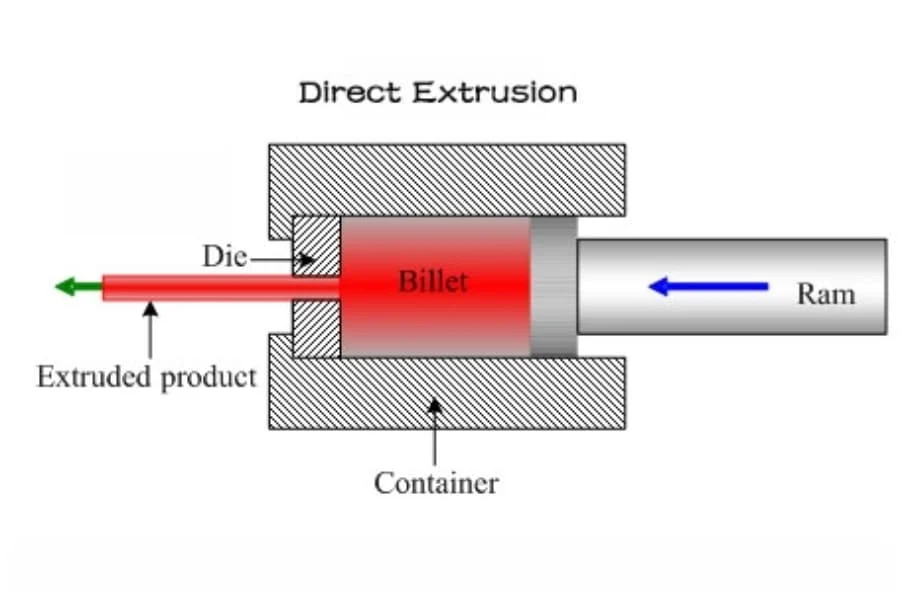

Direct Extrusion

Direct extrusion is most common. During this process, billets are pushed through cavities. Heat and lubrication are usually used to reduce friction. Cut the billet to size after cooling. The extruded product then receives a desired finish.

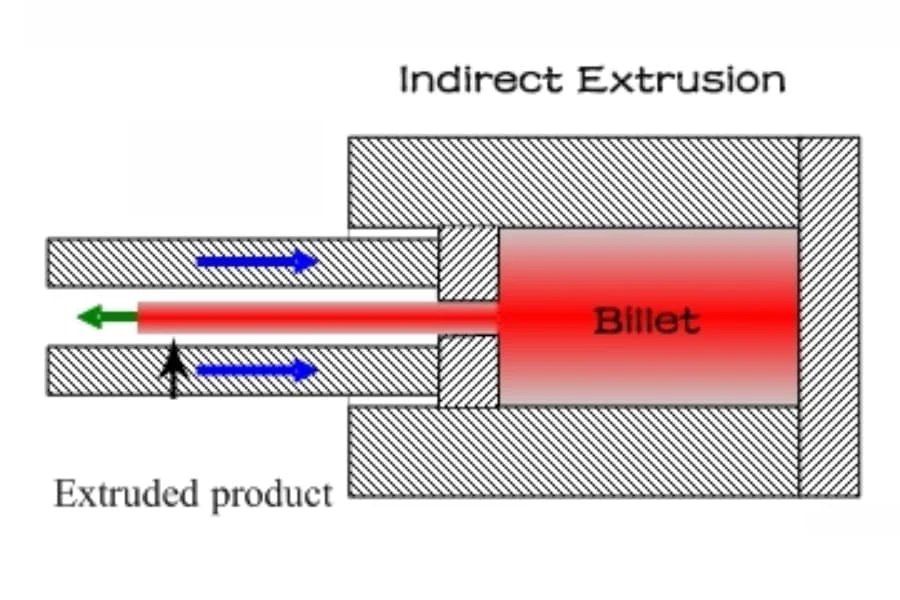

Indirect Extrusion

Indirect Extrusion differs. A hydraulic ram pushes the billet instead of the billet itself. A die is used to force the billet through a die after it has been heated. Extrusion is used to produce hollow shapes like tubes and pipes.

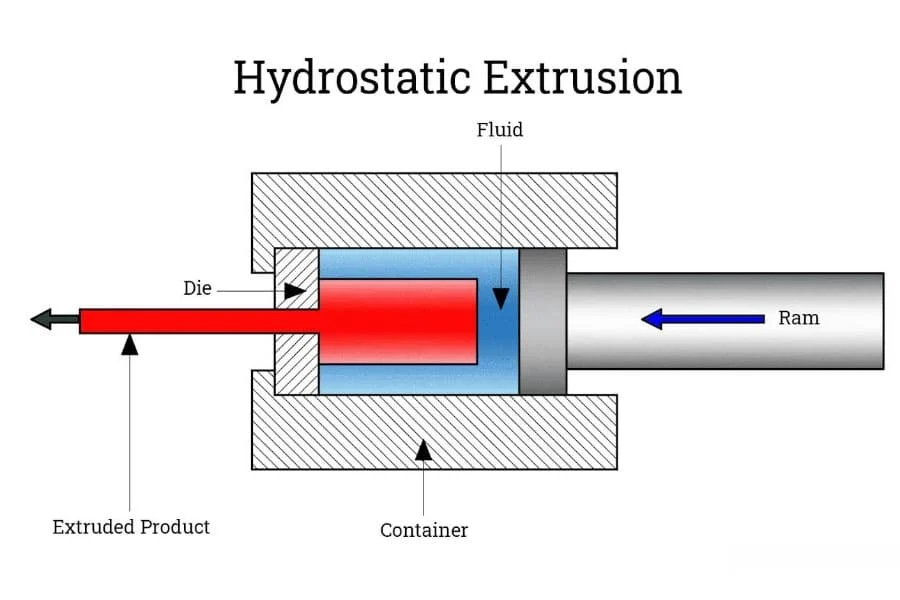

Hydrostatic Extrusion

By using hydraulic fluid, hydraulic extrusion pushes billets through dies. After removing the billet, hydraulic fluid is drained from the system. It offers high levels of accuracy and repeatability, making it a popular high-volume process.

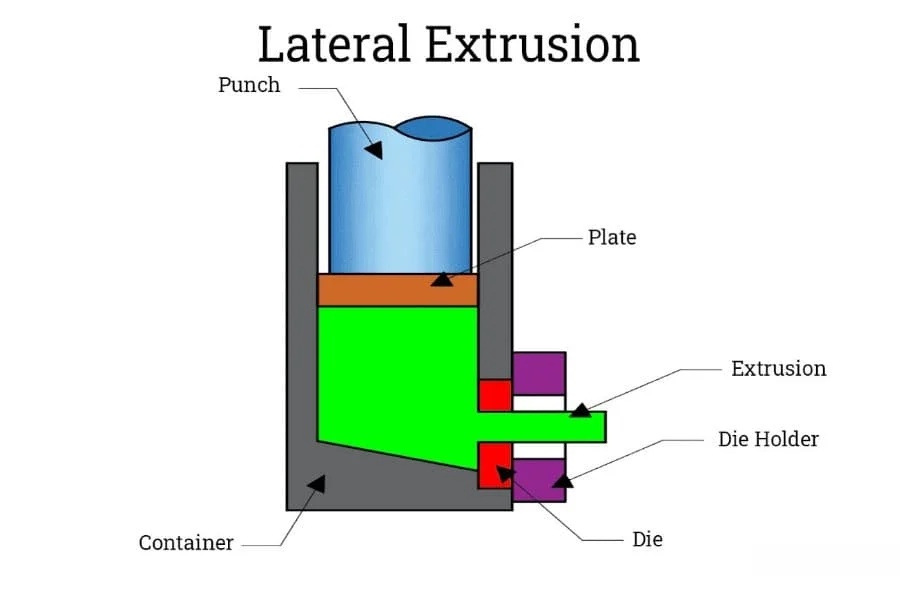

Lateral Extrusion

Material is usually melted during lateral extrusion. This process involves positioning the die on the side. In order to form the desired shape, molten material is extruded through the die. After cooling or quenching, the material solidifies into a solid state.

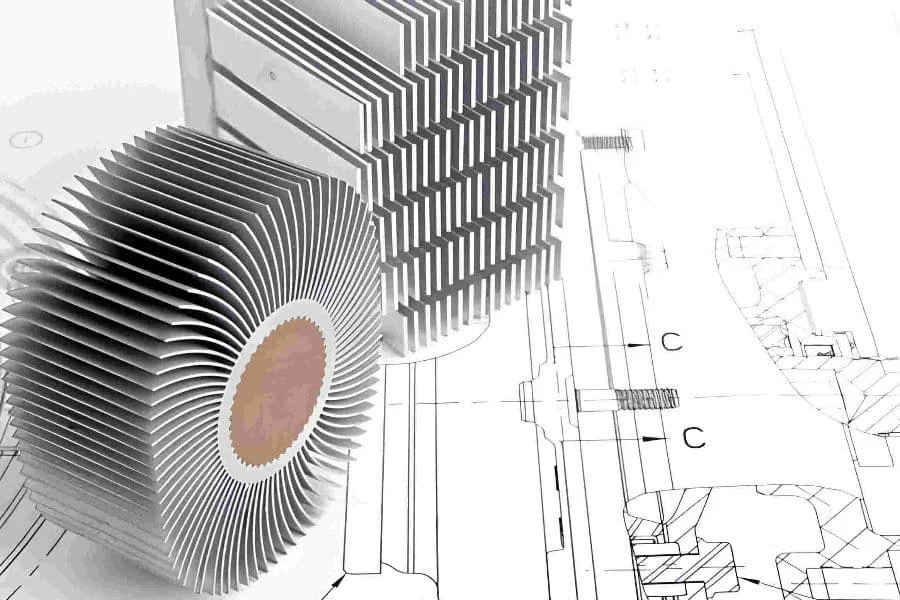

Aluminum Extrusions

Due to its versatility across industries, mechanical properties, diverse finishing options, and high ductility, extruded aluminum makes up about 80% of all extruded metal products. It has high thermal and electrical conductivity, is lightweight, and is resistant to corrosion.They are also cost-effective and recyclable, making them attractive for a variety of applications. A variety of uses can also be achieved with them, as they are durable and strong. Therefore, extruded aluminum alloys are a cost-effective and versatile choice for various applications.

Aluminum Alloys for Extrusion

In electronics, consumer goods, aerospace, and automotive, EPRO uses different grades of aluminum. In addition to excellent mechanical properties, these alloys are corrosion-resistant and easily machined. These alloys are also lightweight and strong, making them ideal for applications requiring strength and durability.

Alloy 6061

6061 aluminum boasts high weldability, toughness, and corrosion resistance, ideal for automotive, marine, and electronic components.

Alloy 6063

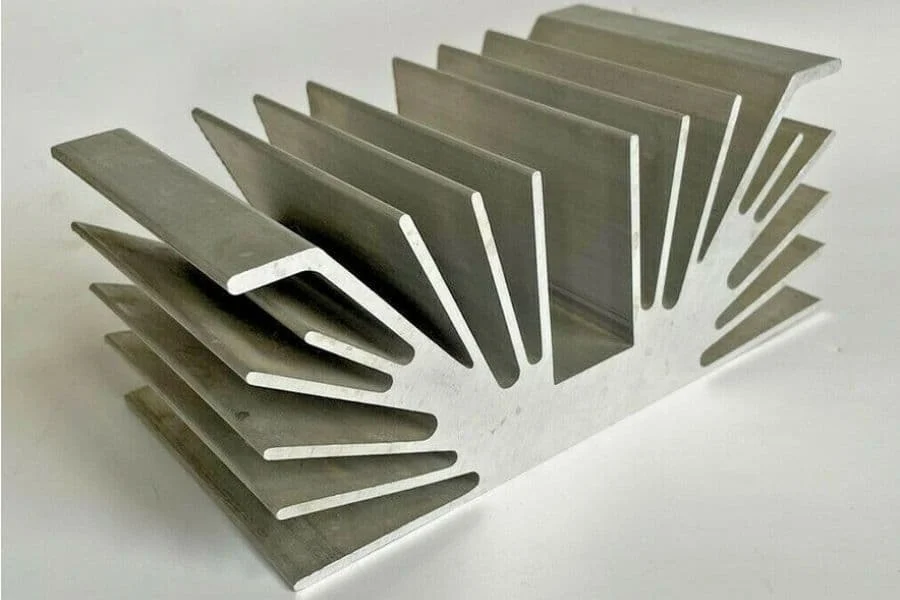

6063 alloy is heat-treatable, cost-effective, with enhanced corrosion resistance and strength, ideal for heat sinks, trims, and architecture; finer grain than 6061 and finishes well.

Alloy 7075

7075 is often used in aircraft and aerospace applications. This alloy boasts good fatigue strength and average machinability, but may have less corrosion resistance.

Alloy 2024

Favored in aerospace for its high strength-to-weight ratio and fatigue resistance. While weldability is limited, 2024 offers good workability and becomes stronger with heat treatment.

Alloy 1100

Purest aluminum alloy, 1100 is known for its superior corrosion resistance, high thermal conductivity, and excellent workability, making it suitable for chemical equipment and kitchenware.

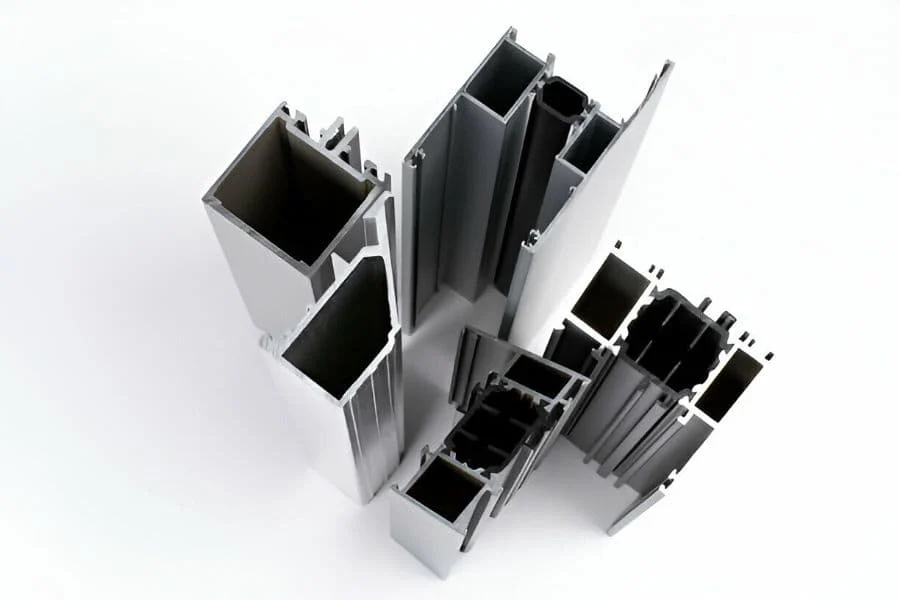

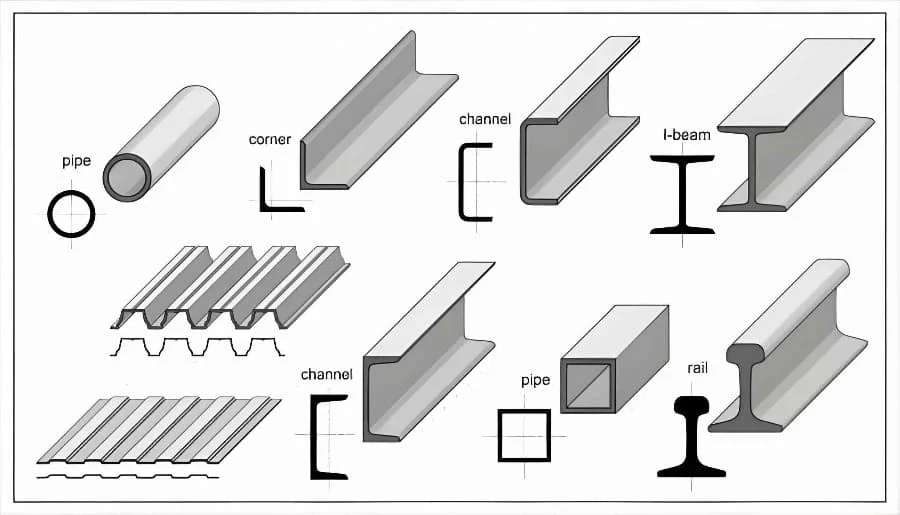

Extrusion Profiles

The profile of an extruded product is the cross-sectional shape.You can also save money and time by post-machining an existing aluminum extrusion profile. These aluminum extrusion profiles can be modified via another manufacturing process, like CNC machining. Customizing existing extrusion profiles without custom extrusion costs is a great option. Additionally, we offer laser cutting, bending, and welding services. Get in touch with us today to learn more!

- Aluminized T-slot extrusions

- Aluminized angles

- H-bars, T-bars, and Z-bars

- Beams of I-shape

- The U-Channel

- The hat channels

- Tubes of rectangular shape

- Pipes and tubes in round shapes

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

The available finishes for extruded parts

No matter what you need, whether it’s functional or cosmetic, we have what you need. We offer a wide variety of metal extrusion finishes. In addition to painted and anodized finishes, we offer various plating options. Powder coating and laser etching are also available. We have unmatched finishing capabilities.

- As-Extruded

- Anodized (Type II Or Type III)

- Powder Coating

- Wet Painting

- Plating

- Chemical Film

- Media Tumbled

- Custom

Available Finishes For Extruded Parts

As-Extruded

Anodized (Type II Or Type III)

Powder Coating

Extrusion aluminum with Painting

As-Extruded

Chemical Film

Media Tumbled

As-Extruded

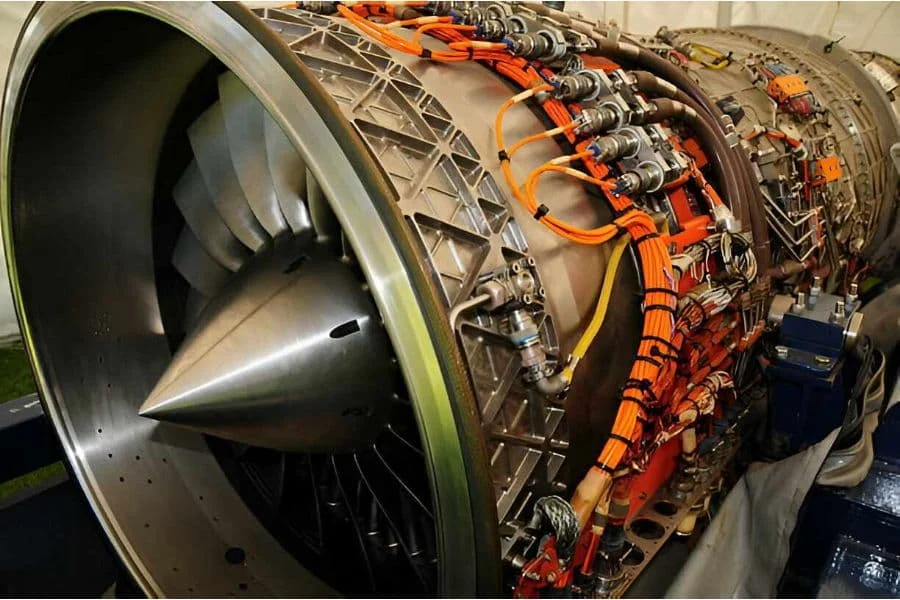

Extrusion Applications

We are surrounded by metal extrusion products every day.In many cases, metal extrusion is the most economical way to create components with continuous complex cross-sections. It is used in industries like automotive, aerospace, marine, architecture, construction, and food processing. Furniture, appliances, and toys are also manufactured using the extrusion process. As well as catheters and implants, it is used in medical components. Therefore, metal extrusion is an invaluable process used in many applications across many industries.

- Aircraft structural components

- Window frames, door frames, trim

- Electrical connector housings

- Conveyors

- Ladders and scaffolding

- Complex thin walled enclosures

- Enclosures for electronics

- LED lighting profiles

- Home appliances

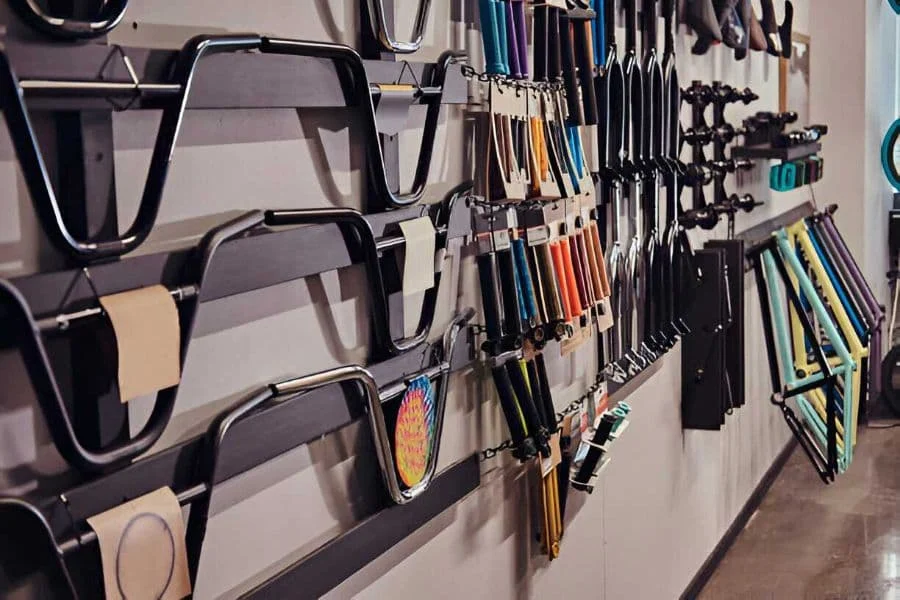

- Automotive components

- Bicycle frames

- Solar panel fra

- Wind turbine components

- Display racks and retail fixtures

- Heat sinks

Using metal extrusion tips

Consider factors like strength and heat resistance when choosing the right alloy. For smoother extrusion, minimize complex features. Enhance material flow and product consistency by optimizing dies.Maintain strict quality control measures to ensure precise dimensions. Enhance your metal extrusion projects with these insights.

Visit our metal extrusion workshop

Experience firsthand how our technicians optimize the extrusion process for maximum efficiency and quality. Every step is meticulously executed to ensure superior results, beginning with the billet and ending with the finished product. We invite you to join us on this immersive tour and discover why our metal extrusion services are second to none.

Gallery Of Metal Extrusion Parts

Check out our display of Metal Extrusion Parts. At EPRO, you can confidently get the best Metal Extrusion parts!