Precision CNC machining

Precision CNC machining – what is it?

High-accuracy, low-tolerance parts are manufactured using computer-aided tools under precision CNC machining. Rather than standard CNC machining EPRO-Rapid precision milling it offers better servo precision to ensure components are produced to meet precise design specifications. The accuracy and precision required for this method are essential for an industry where precision and detail is key, and the end product must maintain the highest levels of quality.

Accuracy – what does it mean?

An accurate dimension is near to a dimension; a measurement is close to a measurement. An accurate reading implies that the value measured isn’t very different from the reference. The precision CNC machining must be accurate enough so that the final product as per the dimensions mentioned can come out. Due to its accuracy and precision, CNC machining guarantees consistent execution of parts and smooth assembly.

Precision: what is it?

Precision: machining 200 parts of the same dimension. Reliability is the cornerstone of precision. CNC machining yield parts that are accurate and dimensional, making the parts easy to assemble and interchangeable. Industries such as aerospace and the manufacturing of medical devices require precision.

Get Your Precision CNC Machining Quote

Choose EPRO-Rapid for precision CNC machining that guarantees both accuracy and consistency. Ensure your parts meet design specifications every time. Click now to request a quote and experience unmatched quality!

EPRO Precision CNC machining: why choose us?

Qualifications

Our staff is qualified to provide high-quality precision CNC machining. We have more than ten years of experience and our parts are made to the strictest industry standards, helping you to alleviate your quality concerns effectively.

An Evolution in the Making

We are constantly investing in cutting edge technology and training. We are committed to getting even better so that we are both more operationally efficient and continue to lead the industry with best-in-class precision CNC machining solutions.

Operational Quality and Efficiency

Our state-of-the-art facility operates with high efficiency and precision. By optimizing processes, we reduce lead times and costs, addressing your need for reliable and cost-effective machining services.

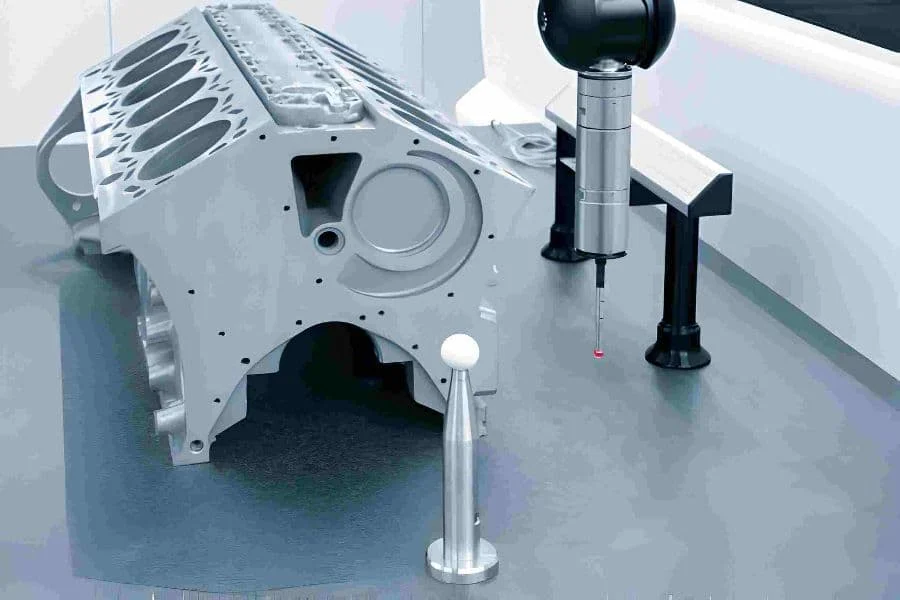

Effective Measurement System

Utilizing advanced measurement systems, we ensure each part meets exact specifications. This rigorous quality control guarantees consistency and accuracy, resolving any issues related to part precision and reliability.

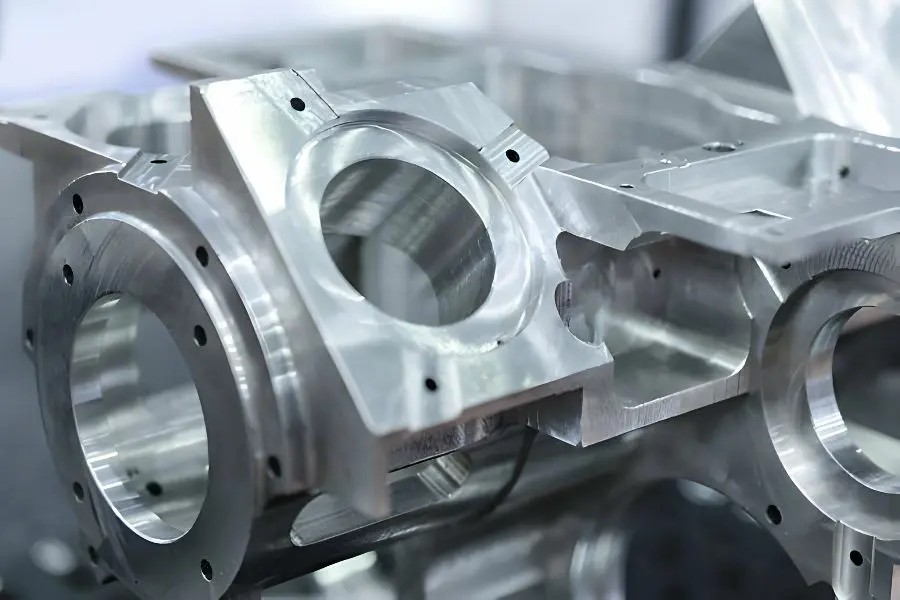

The Precision Machining Capabilities we offer

We offers precision turning, milling, grinding, and EDM capabilities. We have more than 20 years of experience and In house engineering which makes Home Turnkey the perfect choice for your projects. We then have our experts who guarantee the production of high-quality parts in an expedient and precise manner. For precision CNC machining that is held to the highest standards of accuracy and quality, choose EPRO.

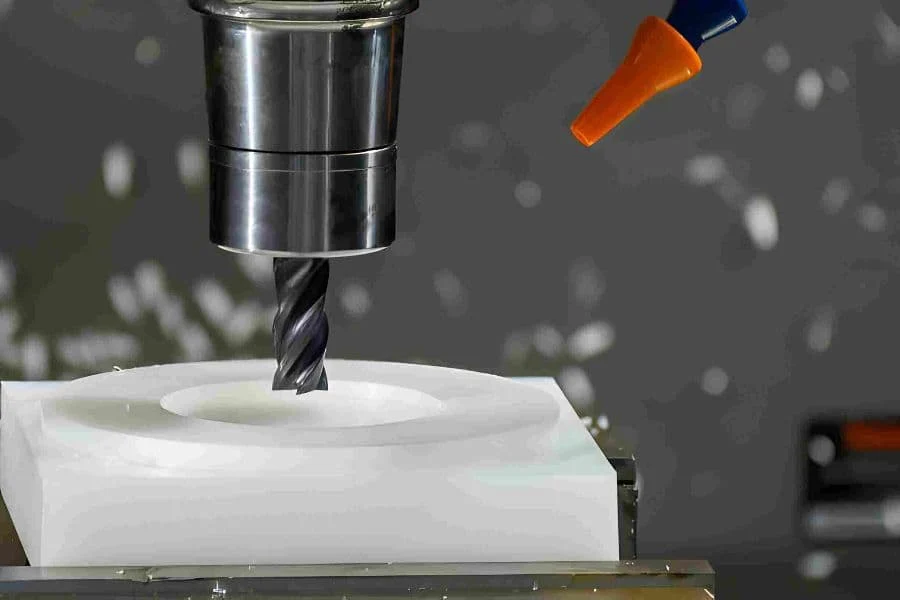

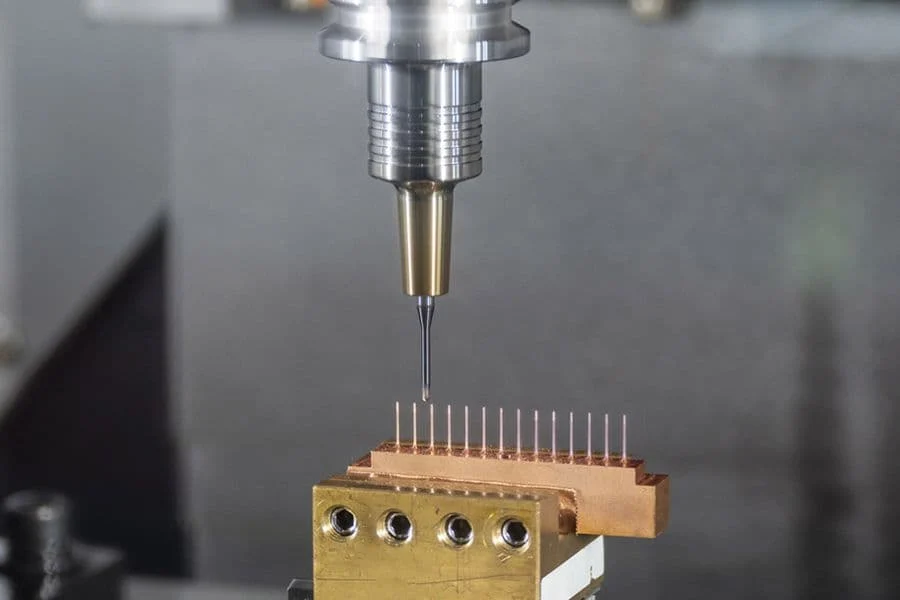

Precision Milling

Our CNC precision milling services use advanced horizontal and vertical mills to create complex parts with tolerances down to 0.005mm. This capability ensures high-quality and precise components, making it ideal for aerospace, medical, and automotive applications. We prioritize precision and quality, offering custom design services to meet your specific needs.

Precision Turning

EPRO’s precision turning process involves cutting rotating materials with a single-point cutting tool, perfect for producing tubular and round parts. This automated method is cost-effective and ideal for creating medical implants, automotive parts, and aerospace components, ensuring high precision and complex shapes.

Precision Grinding

Surface, centerless, and O.D.-grinding capabilities producing super-finishes and highly accurate dimensions. Critical capabilities for aerospace and medical applications where exact dimensions and high performance are required. Our team of experts provides dependable and precision work.

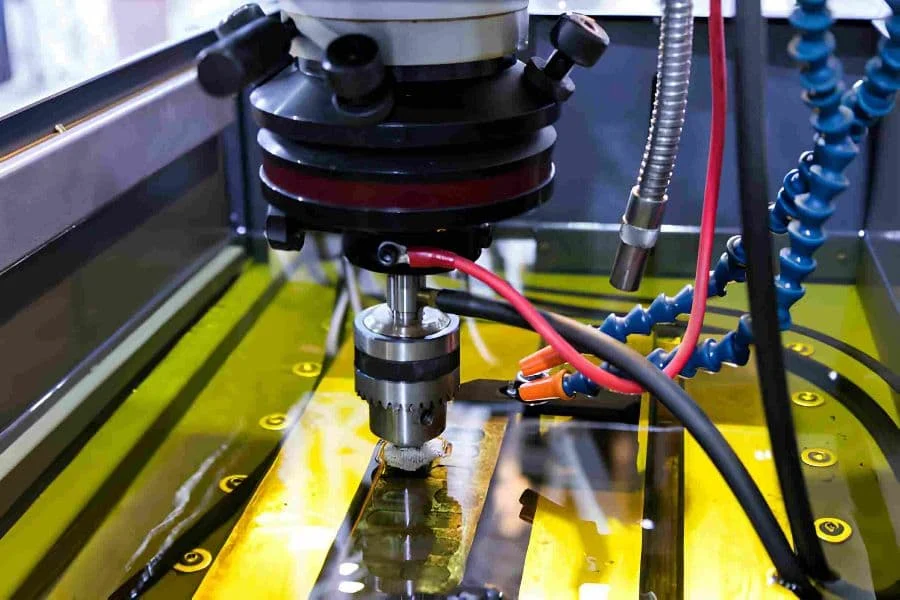

EDM and Wire EDM

We use electrical discharge to get high-quality results and incredible details. The manufacturing of electrodes and wiring is a suitable approach for the production of electrodes and wiring complex geometries with low volumes or single items. They still can be utilized in applications requiring precision like automotive, aerospace, and automotive.

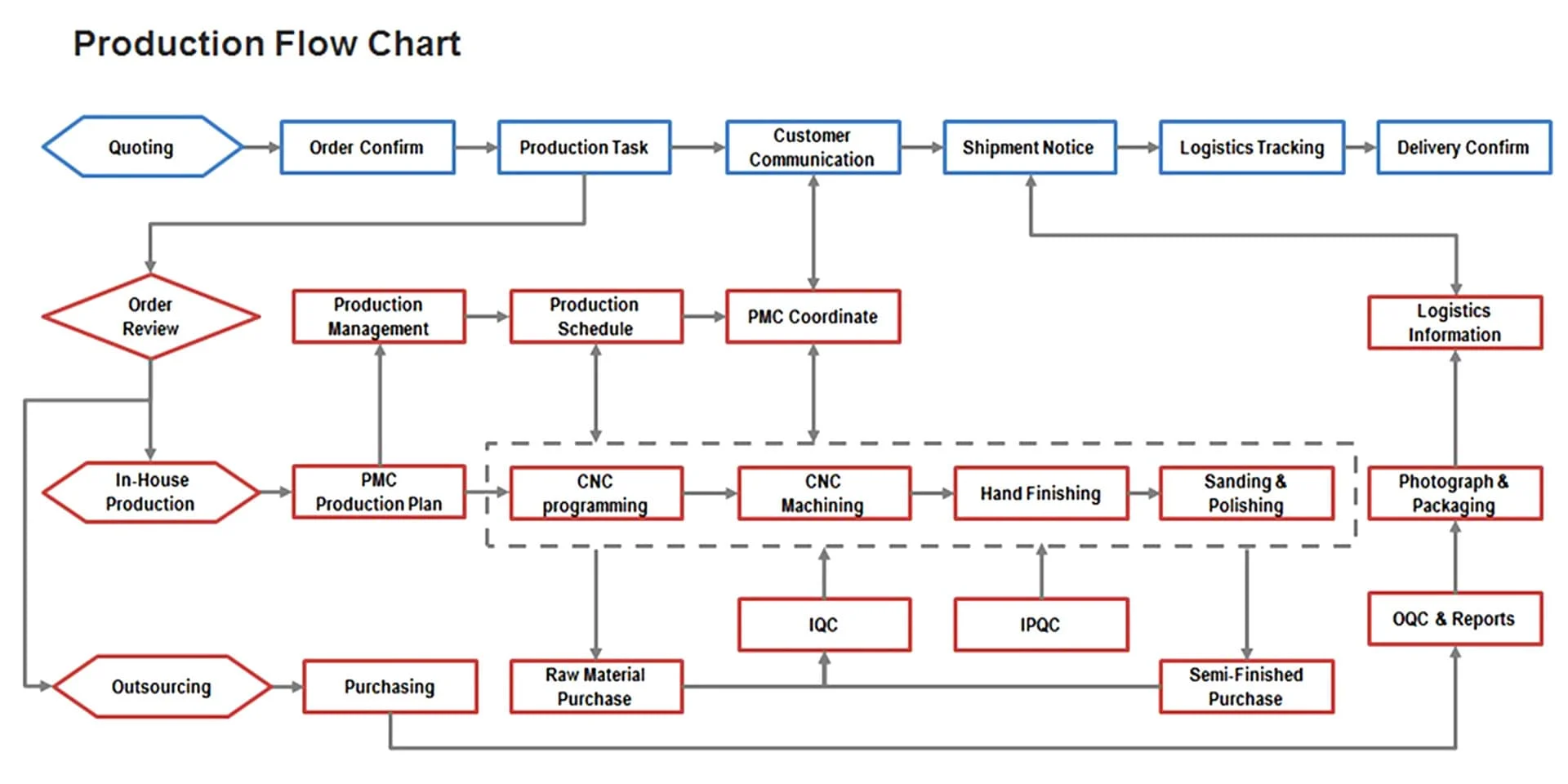

How We Proceed Your Order?

Here is our Pruduction Flow Chart.On this chart,you can see what we proceed your order.

CNC Milling for Various Industrial Applications

EPRO-Rapid’s CNC milling services deliver precision and reliability across industries. Aerospace demands high-tolerance parts, automotive requires durability, and medical devices need intricate accuracy. We address these pain points with advanced CNC milling, ensuring quick turnaround and consistent quality.

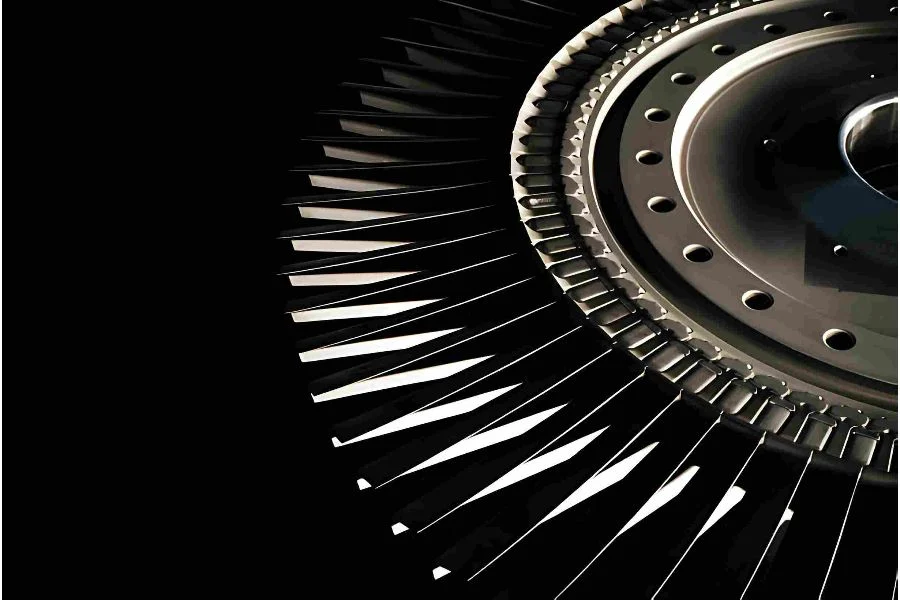

Aerospace & Defense

Our CNC milling delivers high-precision, complex components essential for aerospace and defense. We address industry demands for tight tolerances and robust materials, ensuring parts meet stringent safety and performance standards.

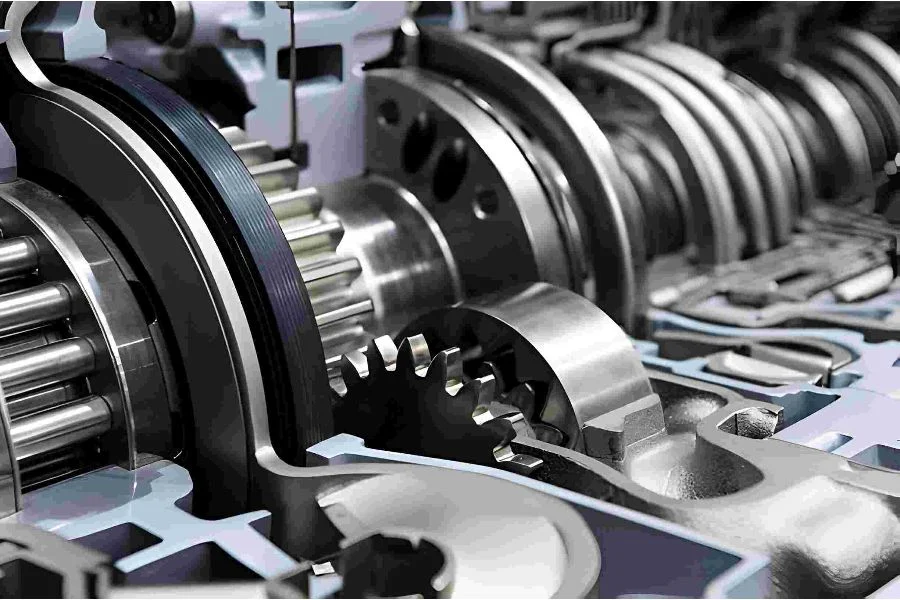

Automotive

In the automotive sector, CNC milling is crucial for producing durable, high-performance parts. EPRO-Rapid addresses the need for precision and repeatability, enhancing vehicle reliability and efficiency with expertly milled components.

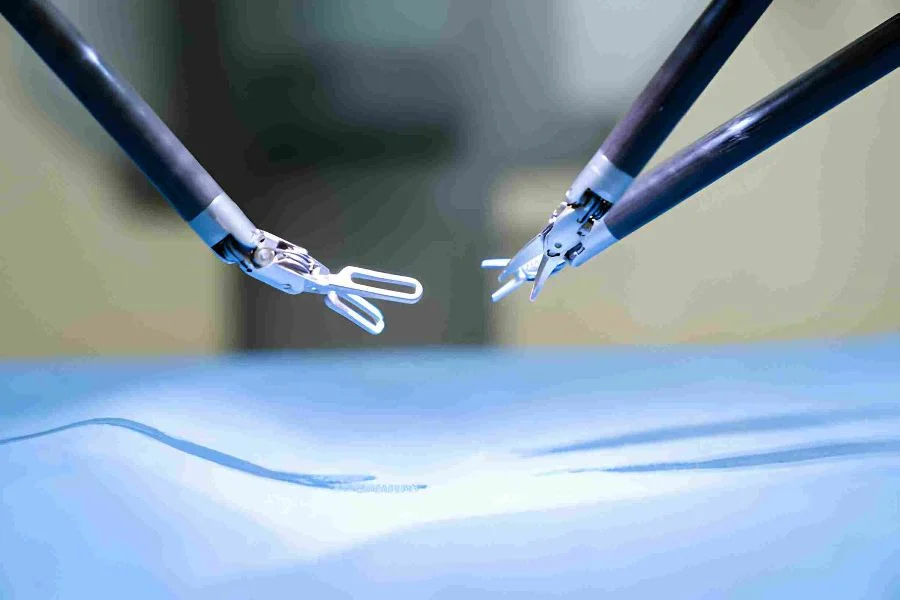

Medical

For the medical industry, CNC milling provides the accuracy required for intricate, high-precision devices and implants. Our services ensure biocompatibility and stringent quality control, vital for patient safety and product efficacy.

Robotics and Automation

We support robotics and automation with precisely milled parts that ensure seamless integration and high functionality. Our CNC milling solves the need for consistent, reliable components in complex robotic systems.

Consumer Products

Our CNC milling enhances consumer products by producing aesthetically pleasing and functional components. We address the demand for high-quality, cost-effective manufacturing, ensuring rapid production without compromising on quality.

More Industries

Design services

New energy

Electronics & Semiconductor

Education

Industrial Machinery & Equipment

Supply Chain and Purchasing

Design Guidelines for Precision Machining

Maximum Dimensions

3-axis Milling | 36 in. x 24 in. x 13 in.

5-axis Milling | 16 in. x 16 in. x 16 in.*

Turning | 10 in. x 18 in.

*Raw block weight limit up to 75 lbs.

Maximum Dimensions

3-axis Milling | 914.4mm x 609.6mm x 330.2mm

5-axis Milling | 406.4mm x 406.4mm x 406.4mm*

Turning | 254mm x 457.2mm

*Raw block weight limit up to 75 lbs.

Minimum Dimensions

3-axis Milling | 0.10 in. x 0.20 in. x 0.20 in.

5-axis Milling | 0.10 in. x 0.20 in. x 0.20 in.*

Turning | 0.093 in. diameter

Feature | 0.0156 in.

Wall Thickness | 0.040 in.**

*Minimum material thickness for plastic and steels: 0.125 in.

** Material and geometry dependent

Maximum Dimensions

3-axis Milling | 2.54mm x 5.08mm x 5.08mm*

5-axis Milling | 2.54mm x 5.08mm x 5mm*

Turning | 0.093 in. diameter

Feature | .396mm

Wall Thickness | 1.016mm**

*Minimum material thickness for plastic and steels: 3.175mm

** Material and geometry dependent

Put your parts into production today

All information and uploads are secure and confidential.

Precision CNC Machining Materials

Select + Compare + Quote from premium quality materials for precision CNC machining We specialize in high accuracy and intricate detailing of aluminum, copper, brass, titanium, and plastics. We make every piece with precision CNC machining to ensure the best quality and precision in every component. From lightweight to high-strength, to corrosion-resistant parts, the precision and quality we deliver will ensure your projects will reach their full potential.

Aluminum

With the right lightness concentricity and zu sehr affordable price point, Aluminium is suitable for aconitum blank machining. Thanks To Its High Strength-to-Weight Ratio, Corrosion Resistance, Aerospace, Automotive, And Consumer Electronics Uses.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Aluminum

Copper has amazing electrical & thermal conductance and is highly coveted. It is suitable for parts in electrical applications that require tight tolerances and effective heat dissipation; these applications may include heat sinks and electrical connectors.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Brass

Known for its machinability and corrosion resistance, brass is perfect for applications such as plumbing, electrical applications, among general applications, and even decor.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is extremely durable and naturally resistant to corrosion. Well suited for medical, automotive and food processing equipment where sterilization and durability are paramount.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Titanium

Titanium is used in many different types of applications, and helps to offer high strength, low weight, and is also incredibly corrosion resistant. Used in aerospace, medical implants, and high-performance auto parts involving where strength and biocompatibility is very important in these parts.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Plastics

Such as ABS, POM and Nylon.With plastics, you can get closest because CNC machining of plastics provide excellent versatility for producing lightweight, durable components. They are versatile and cost-effective, which makes them a popular choice in consumer electronics, automotive interiors, and medical devices.

| POM | PEEK | HDPE | PET |

| Nylon | PTFE | PVC | PP |

| ABS | PC | PMMA |

Tour Our Precision CNC Machining WorkShop

Check out our modern precision CNC machining shop filled with the latest equipment and run by experienced machinists. We comply to the best industry practices to execute work in an efficient and quality form believe in. See the dedication to precision, innovation and excellence. Book your tour now so you can experience for yourself how we can take your project from concept to reality with optimal precision and highest quality.

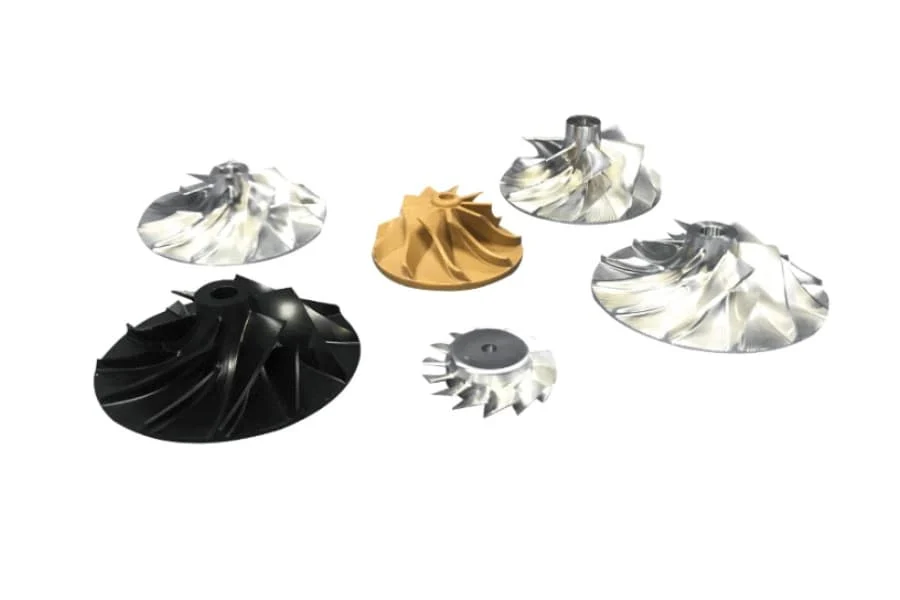

Gallery Of 5-axis CNC Machining Parts

Discover our 5-axis CNC machining parts for aerospace, automotive, medical, robotics, and consumer products. We utilize diverse materials like aluminum, titanium, and stainless steel, with finishes such as anodizing and polishing, ensuring top quality and precision.