CNC Turning Services

What is CNC Turning?

The CNC turning process involves rotating a metal rod while holding a cutting tool against the stock in order to remove material. Live tooling is also available on our CNC lathes for machining flat features and holes in workpieces. There are also threads with outside diameters (OD) and inside diameters (ID). It is generally considered to be a cost-effective method of creating complex, precise parts using CNC turning.

Bead blasting is an option for parts that have been machined, but have visible tool marks. The parts are inspected, packaged, and shipped soon after the run is complete. In some cases, additional processing steps may be required, such as washing or painting. The quality control process ensures that the parts meet the specifications of the customer as well. Once the parts have been shipped to the customer, the production process is complete.

Why Choose CNC Turning?

Precision-machined rotary surfaces

CNC turning yields micro, high quality finishes on rotary components crucial to components with extremely specific tolerances for quality and performance improvements.Let’s get start now!

Effortless and automated

CNC turning is an automated process which minimizes the chances of manual blunder. This efficiency helps us maintain high levels of quality, enables expedited production times, and ensures cost effective manufacturing.

Different material are compatible

Ideally, CNC turning is versatile, and it can work with various materials such as aluminum, steel, and plastics. This flexibility based on industry requirements variedly.

Enable multi-tasking

For instance- CNC machine tools nowadays can provide more than just the basic part turning process, all in a setup (mill-drill-turn) which further reduces the overall time (cycle time) consumed for complex parts.

CNC Turning Quote Times

Receive a quick and precise quotes for your CNC turning requirements. Gut Instinct with EPRO-Rapid Request your CNC Turning quote today!

CNC Turning Materials

Our CNC Machining services can handle virtually any material for Rapid Prototyping and Production Runs. Receive instant quotations on 40+ metals & plastics for your manufacturing requirements.

Aluminum

With the right lightness concentricity and zu sehr affordable price point, Aluminium is suitable for aconitum blank machining. Thanks To Its High Strength-to-Weight Ratio, Corrosion Resistance, Aerospace, Automotive, And Consumer Electronics Uses.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Aluminum

Copper has amazing electrical & thermal conductance and is highly coveted. It is suitable for parts in electrical applications that require tight tolerances and effective heat dissipation; these applications may include heat sinks and electrical connectors.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Brass

Known for its machinability and corrosion resistance, brass is perfect for applications such as plumbing, electrical applications, among general applications, and even decor.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is extremely durable and naturally resistant to corrosion. Well suited for medical, automotive and food processing equipment where sterilization and durability are paramount.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Titanium

Titanium is used in many different types of applications, and helps to offer high strength, low weight, and is also incredibly corrosion resistant. Used in aerospace, medical implants, and high-performance auto parts involving where strength and biocompatibility is very important in these parts.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Plastics

Such as ABS, POM and Nylon.With plastics, you can get closest because CNC machining of plastics provide excellent versatility for producing lightweight, durable components. They are versatile and cost-effective, which makes them a popular choice in consumer electronics, automotive interiors, and medical devices.

| POM | PEEK | HDPE | PET |

| Nylon | PTFE | PVC | PP |

| ABS | PC | PMMA |

Basic Types Of CNC Turning Processes

O.D. and I.D. Turning

It is used for machining precise cylindrical features. Precision cylindrical features can be machined with this tool. During turning, tool marks remain visible, indicating how deep the part was machined (tool used: general turning tool).

Parting and Grooving

The Parting and Grooving Inserts can be used to part off or groove interior and exterior parts of a part. Material is removed from the surface when the tool is moved. Cutting speed and geometry determine the depth of a groove. Create holes, slots, and other shapes with inserts with grooves and partings.

Facing

A facing tool is used to flatten a workpiece’s surface (Tool used: Facing tool) The tool works in a circular motion to smooth the surface. In this operation, a flat surface is created that can be machined.

Boring and Reaming

Tools for boring and reaming holes can be used in metal, plastic, and other materials. Increasing or finishing existing holes can achieve highly accurate diameters. Precision holes are commonly used in machining and other applications. Threading holes can also be done with boring tools.

Drilling

Using drills, drill holes in metal, wood, and other materials by removing materials from the inside. The size, shape, and speed of these machines vary, and their application possibilities are numerous. Different drill bits are available in different sizes and shapes.

Threading

It is possible to machine threads by turning a workpiece internally or externally. The threading tools are usually made of high speed steel and come in a wide variety of shapes. Taps and dies are used for machining internal and external threads. Threading tools can also be used to create slots and keyways.

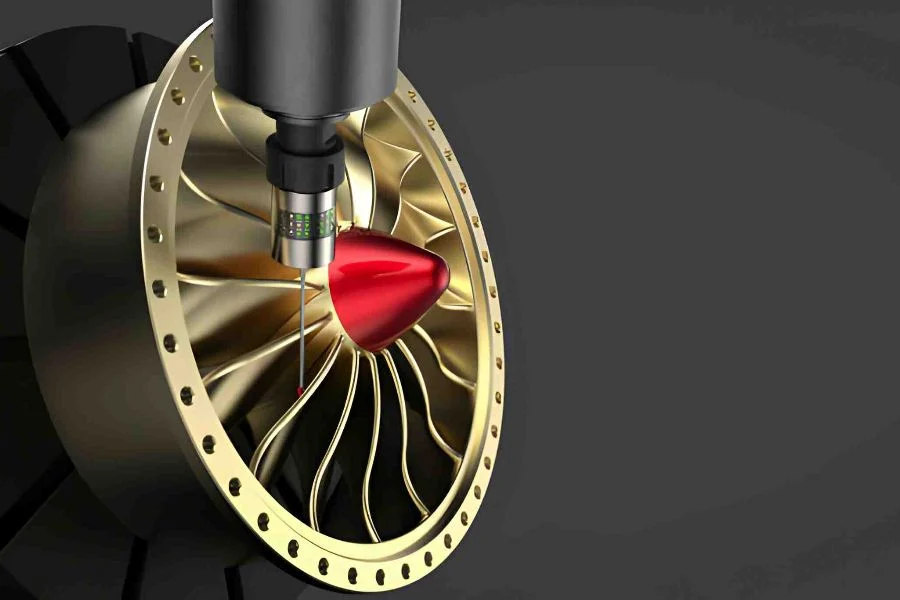

CNC Milling for Various Industrial Applications

EPRO-Rapid’s CNC milling services deliver precision and reliability across industries. Aerospace demands high-tolerance parts, automotive requires durability, and medical devices need intricate accuracy. We address these pain points with advanced CNC milling, ensuring quick turnaround and consistent quality.

Aerospace & Defense

It requires precision CNC turning to reach high-strength, light parts with small tolerances. Those high-precision flanges and fittings that your client uses on an airplane or in a defense application are made right in our turning centers and meet the most exacting standards of the industry.

Automotive

Our CNC turning services are perfect for producing high-quality and long-lasting parts of the engine and transmission systems in the automotive industry. We fulfil the requirement of high-performance, trustworthy parts that enhance vehicle effectiveness and security.

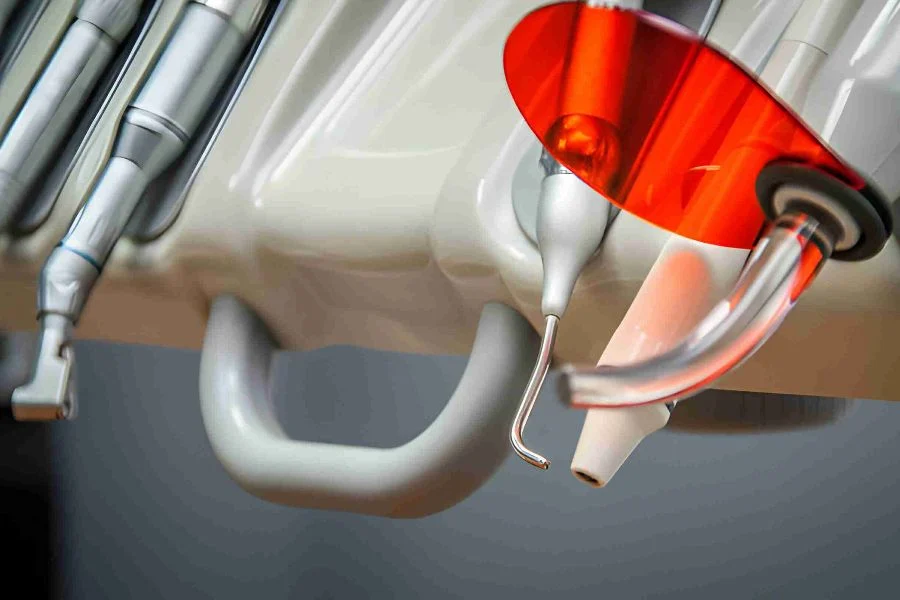

Medical

CNC turning supplies an assortment of medical parts and components for the manufacturing of medical implants and surgical instruments. Our CNC turning centers provide biocompatibility and comply with exact biomedic standards in order to afford additional benefits to patient care.

Robotics and Automation

In the creation of robotic and automation systems, CNC turning is very important to manufacture parts that are accurate and that over time are resistant. We provide superior components designed to meet the demanding requirements of automated applications to guarantee performance and longevity.

Consumer Products

High qulaity CNC Turning is used in producing consumer products in order to make a wide range of high quality, funtional parts that look good. We can do this in a variety of industries, including electronics and consumer products such as home appliances to produce strong, precision-engineered parts that meet consumer standards.

More Industries

Design services

New energy

Electronics & Semiconductor

Education

Industrial Machinery & Equipment

Supply Chain and Purchasing

Surface Finish Options for Turned Parts

Turned parts are typically very smooth. CNC turned parts can be finished in several ways. A polished finish creates a mirror-like appearance, a brushed finish creates a textured appearance, and anodized finishes add durability and protection.

If you are machined with a lathe, the surface finish will be smoother than with a mill. To achieve a fine matte finish, metal parts can be bead blasted lightly to remove tool marks. Bead blasting can also be used to remove metal slivers and sharp edges from stainless steel and steel.

CNC Turned Aluminum

CNC turned aluminum parts are most capable of being anodized, which adds corrosion resistance and also allows for a variety of bright colors. Polishing results in a glossy mirror-like surface, bead blasting delivers an even matte finish to remove tool marks and enhance aesthetics and functionality.

All other metals

Similarly, metals like steel, stainless steel, and brass offer surface finishes such as polishing for a step, polished look or passivation to further prevents corrosion Bead blasting yields the finest matte finish, rounding edges and eliminating imperfections for increased lifespan and performance.

- Material: Aluminum

- Surface Finish: Broken Edge

- Material: Aluminum

- Surface Finish: Bead Blast

- Material: Aluminum

- Surface Finish: Sharp Edge

Put your parts into production today

All information and uploads are secure and confidential.

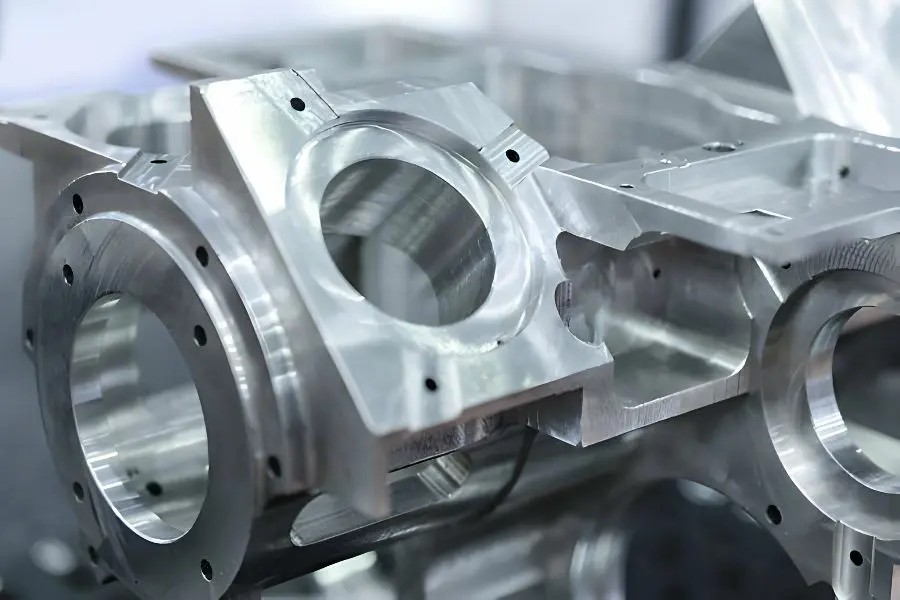

Gallery Of CNC Turning Parts

View our gallery for custom precision CNC turning parts crafted for aerospace, automotive, medical, and consumer industries. The parts are produced in aluminum 7075, stainless steel, titanium and have surface finishings such as anodizing, polishing, and bead blasting. Those represent our depth, breadth and commitment to industry-targeted, high-quality solutions.