Custom CNC Machining Services

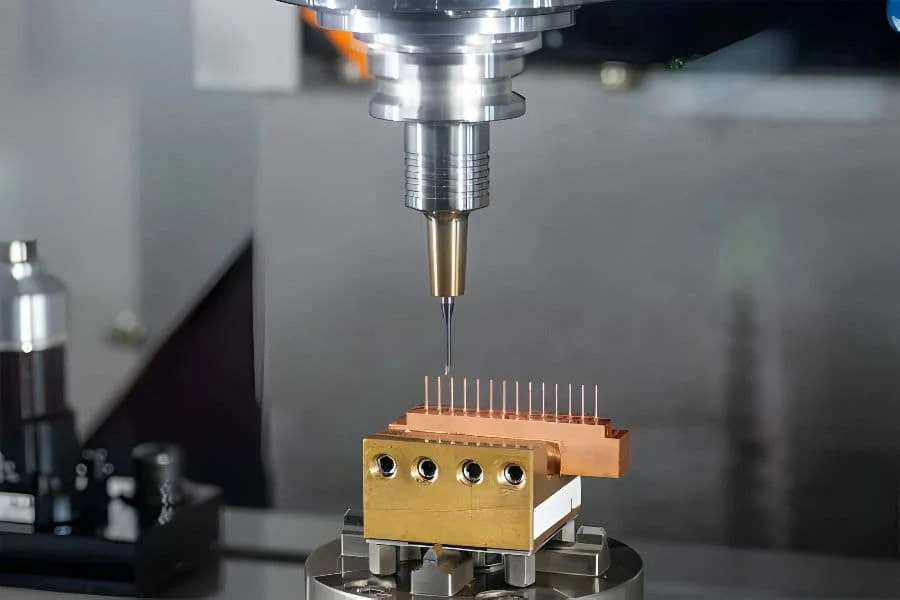

What is CNC Machining?

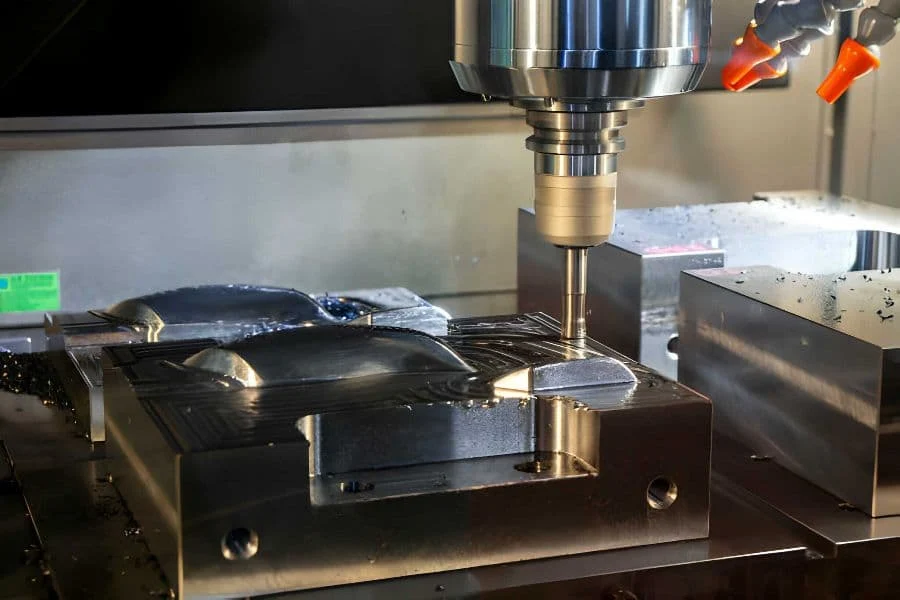

CNC is short for computer numerical control machining, and it is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. So when it comes to CNC machines, it can be a 3, 4, or 5 axis milling machine, 4 or 5 axis lathe or a 5 axis router (or a few others). CNC parts are cut in various ways: there is continuous cutting or the workpiece can be stationary while the tool moves, or the tool can be stationary as the workpiece moves and rotates, or both can move together, etc.

Machining with CNC by EPRO has many advantages

- Achieve Precise Specifications

Our CNC machining services ensure exceptional accuracy, enabling you to achieve precise specifications and tight tolerances critical for high-quality parts.

- Flexibility

CNC machining offers remarkable flexibility, accommodating a wide range of materials and complex geometries to meet diverse project requirements seamlessly.

- The Perfect Solution for Prototyping

Ideal for prototyping, our CNC machining allows for rapid production of detailed prototypes, helping you validate designs and make necessary adjustments quickly.

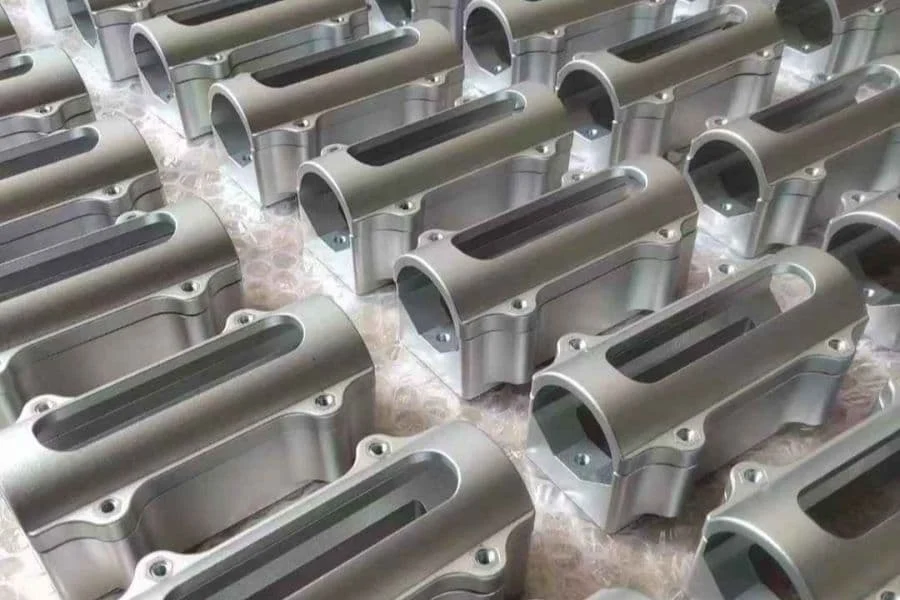

- Scalability

Whether you need a single prototype or large-scale production, our CNC machining services provide scalable solutions to match your project demands efficiently.

We are able to produce 1 to 10,000 pieces upon request

Tight tolerance ±0.05mm , Surface roughness Ra0.2μm

Parts are 100% inspected under ISO 9001:2015 certification

Personalized support , response in 1 hour or less

Put your parts into production today

All information and uploads are secure and confidential.

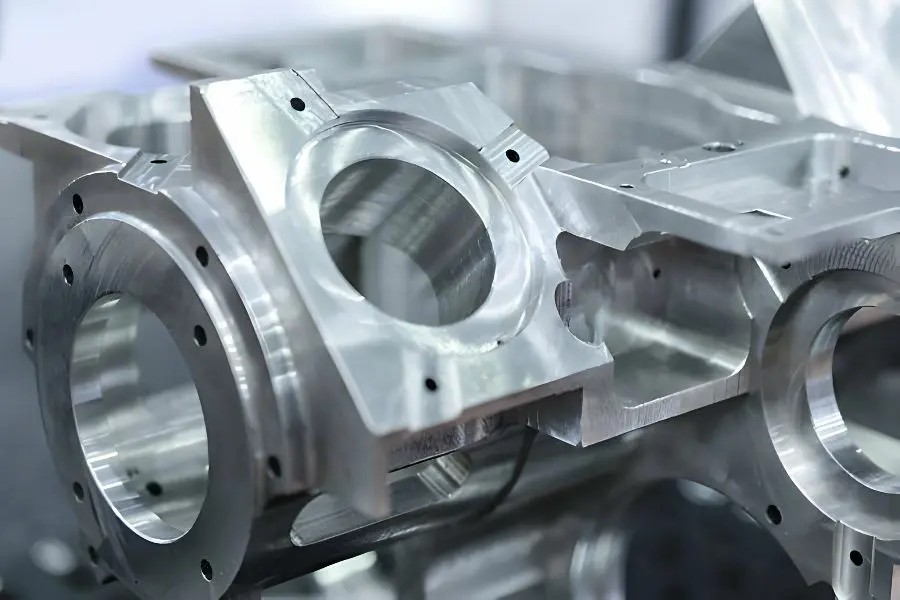

CNC Machining Capabilities

Experience the precision and expertise of one of the leading CNC machining manufacturers in China. We specialize in parts with tight tolerances and complex machining processes. Trust our CNC machining services to deliver exceptional quality and become one of our next satisfied customers.

CNC Milling

Our CNC milling services deliver high-precision parts with intricate details. Ideal for complex geometries and tight tolerances, ensuring your design specifications are met.Get in touch with us!

CNC Turning

EPRO’s CNC turning capabilities produce precise cylindrical parts efficiently. Perfect for components requiring high accuracy and smooth finishes in various materials.Call us today!

5-Axis CNC Machining

Achieve unparalleled complexity and precision with our 5-axis CNC machining. This advanced technology allows for the creation of detailed parts in a single setup, saving time and cost.Try to quote!

Precision CNC Machining

Our precision CNC machining services guarantee exceptional quality and consistency. We specialize in manufacturing parts with exacting tolerances, crucial for critical applications.

Considering the following factors

When Designing for CNC Machining

- Positioning

Proper positioning of the workpiece is crucial for achieving precision. Ensure that the workpiece is securely fixed and aligned correctly to maintain accuracy and avoid misalignment during the machining process.

- Hardness of the Tool

The tool’s hardness should match the material being machined. Harder tools are essential for cutting tougher materials, while softer tools may be suitable for less demanding materials. This ensures efficient cutting and prolongs tool life.

- The Stiffness of the Workpiece

A rigid workpiece minimizes vibrations and deflection during machining, leading to better surface finishes and dimensional accuracy. Design parts with adequate support and rigidity to withstand machining forces.

- Shape and Geometry of CNC Machine Cutting Tools

Selecting the appropriate cutting tool geometry is vital for optimal material removal and surface finish. Consider tool shapes that can efficiently handle specific features, such as sharp corners or deep cavities, to enhance machining performance.

These considerations ensure that your CNC machining projects are executed with precision, efficiency, and reliability.

CNC Machining Materials

Our CNC Machining services can handle virtually any material for Rapid Prototyping and Production Runs. Receive instant quotations on 40+ metals & plastics for your manufacturing requirements.

Aluminum

With the right lightness concentricity and zu sehr affordable price point, Aluminium is suitable for aconitum blank machining. Thanks To Its High Strength-to-Weight Ratio, Corrosion Resistance, Aerospace, Automotive, And Consumer Electronics Uses.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Aluminum

Copper has amazing electrical & thermal conductance and is highly coveted. It is suitable for parts in electrical applications that require tight tolerances and effective heat dissipation; these applications may include heat sinks and electrical connectors.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Brass

Known for its machinability and corrosion resistance, brass is perfect for applications such as plumbing, electrical applications, among general applications, and even decor.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is extremely durable and naturally resistant to corrosion. Well suited for medical, automotive and food processing equipment where sterilization and durability are paramount.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Titanium

Titanium is used in many different types of applications, and helps to offer high strength, low weight, and is also incredibly corrosion resistant. Used in aerospace, medical implants, and high-performance auto parts involving where strength and biocompatibility is very important in these parts.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

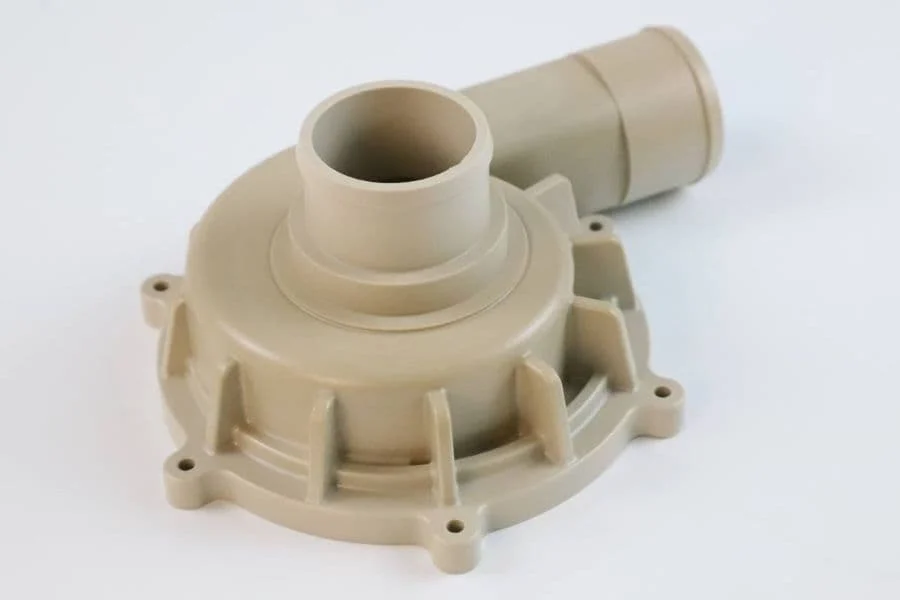

Plastics

Such as ABS, POM and Nylon.With plastics, you can get closest because CNC machining of plastics provide excellent versatility for producing lightweight, durable components. They are versatile and cost-effective, which makes them a popular choice in consumer electronics, automotive interiors, and medical devices.

| POM | PEEK | HDPE | PET |

| Nylon | PTFE | PVC | PP |

| ABS | PC | PMMA |

CNC Machining Surface Finishes

At EPRO-Rapid, we provide a wide range of surface finishes to enhance both functionality and aesthetics. Our finishes ensure your custom parts meet precise specifications and achieve a high-quality appearance, tailored to your unique requirements.

| Image | Name | Description | Material | Color | Texture |

|

Anodizing | Anodizing enhances corrosion resistance, increases surface hardness, and allows for vibrant color finishes. Ideal for aluminum parts, it improves durability and aesthetic appeal, making it perfect for consumer electronics and automotive applications. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. |

|

Bead Blasting | Bead blasting provides a uniform matte or satin surface finish, removing imperfections and creating a smooth, aesthetically pleasing texture. This finish is excellent for reducing glare and preparing surfaces for further coating or painting. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Matte |

|

Powder Coating | Powder coating offers a durable, high-quality finish that is resistant to wear, corrosion, and fading. It provides excellent coverage and uniformity, ideal for parts requiring a robust and attractive surface, such as outdoor equipment and automotive components. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

|

Electroplating | Electroplating is the process in which a very thin layer of metal such as nickel or chrome are added to increase the resistance to corrosion, as well to increase the conducting ability and to increase the hardness of the surface. Which means that this finish is the best finish for decorative use and to get the higher life of the components which are used in harsh and severe environments. | Aluminum, steel, stainless steel | N/A | Smooth, glossy finish |

|

Polishing | Polishing give high glossy surface finish in mirror shine provide attractive look and Smoother Experience. This finish is particularly advantageous for reducing friction, and improves upon the aesthetics within medical devices and consumer products as well. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

|

Brushing | This results in a substantial linear grain on the parts giving an elegant satin finish. Appropriate for parts that require an appealing and non-reflective surface typically utilized in consumer electronics and kitchen appliances. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Satin |

Available Quality Documentation

- CoC

- FAI

- CMM

- Material Test Reports

- Material Certifications

- RoHS

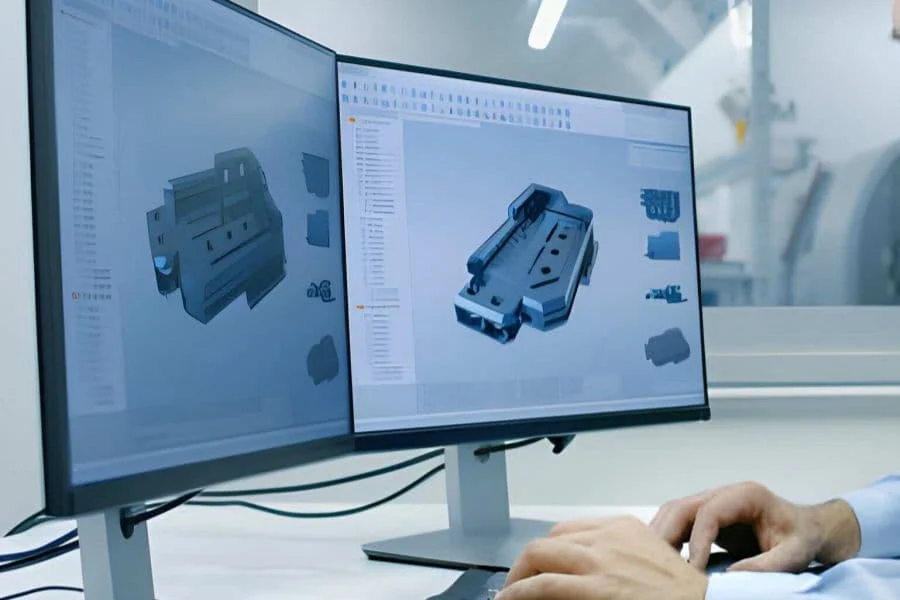

From CNC rapid prototyping to production

Rapid prototyping

Accelerate your prototyping development cycles with our streamlined process:

- Instant quotes

- Real-time DFM feedback

- Efficient order management system

- Live tracking of deliveries

Production

Ensure consistent quality and cost efficiency for every production order with our dedicated team:

- Personalized project manager

- DFM cost optimization engineers

- First Article Inspection (FAI) for precision and accuracy

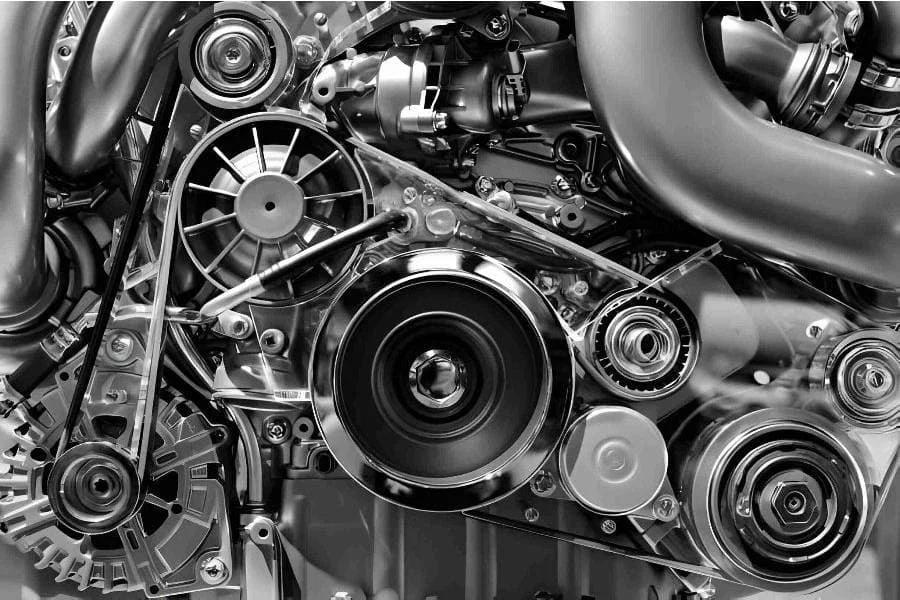

Applications for CNC Machining Parts

Dive into the world of CNC Machining and explore its vast applications across Aerospace & Defense, Automotive, Medical, and Robotics & Automation industries. From intricate components for aerospace engines to precision parts for medical devices, our CNC machining services deliver unmatched quality and reliability to meet the demanding needs of modern engineering.

Precision-machined Aerospace Parts Include:

Cabin Parts

Wing Ribs

Fuselage Components

Actuators

Motion Controls

Engine Housings

Landing Gear Components

Discs

Filter Bodies

Precision-machined Automotive Parts Include:

Lighting

Engines

Cylinder Heads

Gearboxes

Interior Panels

Drive Axles

Interior Panels

Starter Motors

One-off Custom Components for Rare

Precision-machined Medical Parts Include:

Hip Replacements and Knee Implants

Surgical Tool Production

Electronic Medical Equipment

Custom Prosthetics

Small Orthopedic Hardware

Medical Device Prototypes

Dental Tools and Implants

Implant Holders

Biopsy Tubes

Precision Robotics and automation Parts Include:

Robotic Arm

End Effectors

Custom Jigs and Fixtures

Sensors and Controllers

Structural Components

Gears

Modular Tooling

Robotic System Motor Components

End of Arm Tooling

Put your parts into production today

All information and uploads are secure and confidential.

Tour Our 5 Axis Machine Shop

Check out our incredible line of well-functioning 5-axis machining centers ranging from the best 5-axis horizontal machining center to top-notch vertical machining centers. These are ideal facilities for manufacturing components for various industries. We combine advanced technologies with skilled technicians to deliver results to suit your needs perfectly.

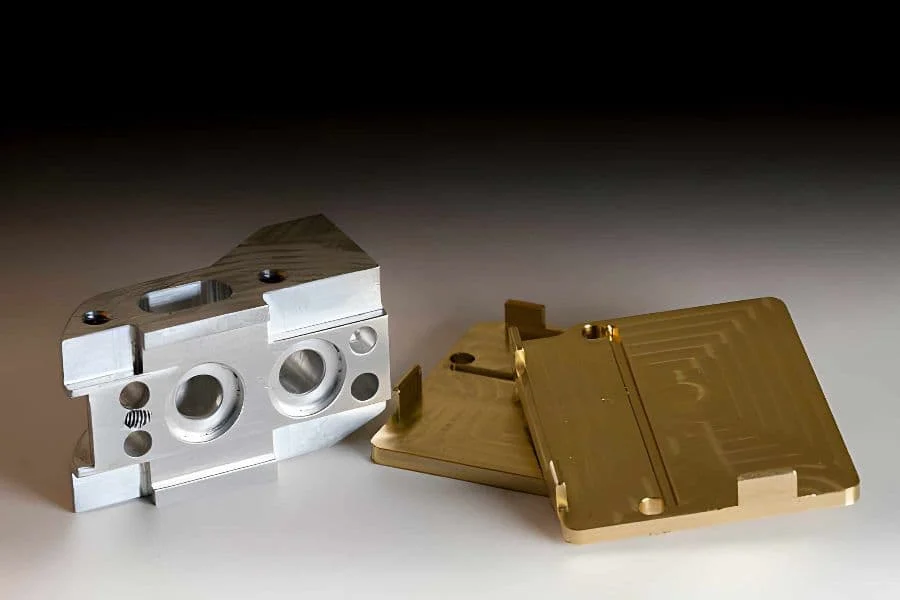

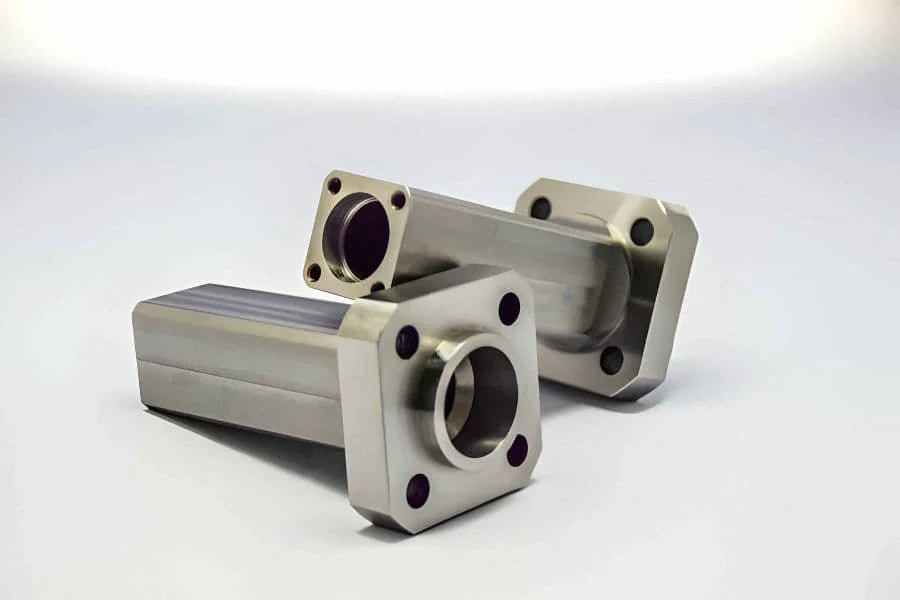

Gallery Of CNC Machining Parts

Explore our gallery showcasing a diverse range of CNC machined parts used across various industries. From aerospace to automotive, medical devices to consumer electronics, our precision-engineered components meet the highest standards of quality and performance.