Business Overlay

Our partner network delivers around the world, fast.

NOTE:Numbers based on 2024 stats at EPRO

Our Quality Management System

Providing our customers with the best quality parts is of the utmost importance to us. That’s why we have a complete quality management system in place that is ISO 9001:2015 certified. Our quality system enables us to meet our customers’needs and exceed their expectations.

Quality begins with communication and collaboration. So, we start every project by working to gain a clear understanding of the customer’s specifications and requirements so that we can see the project through to its successful completion.

Efficiency is important in manufacturing, so we strive to produce every part right the first time. Our QC department works tirelessly to ensure that we’re on track and nothing slips through the cracks. When the customer is delighted by our quality and service, that’s when we know we’ve done our job.

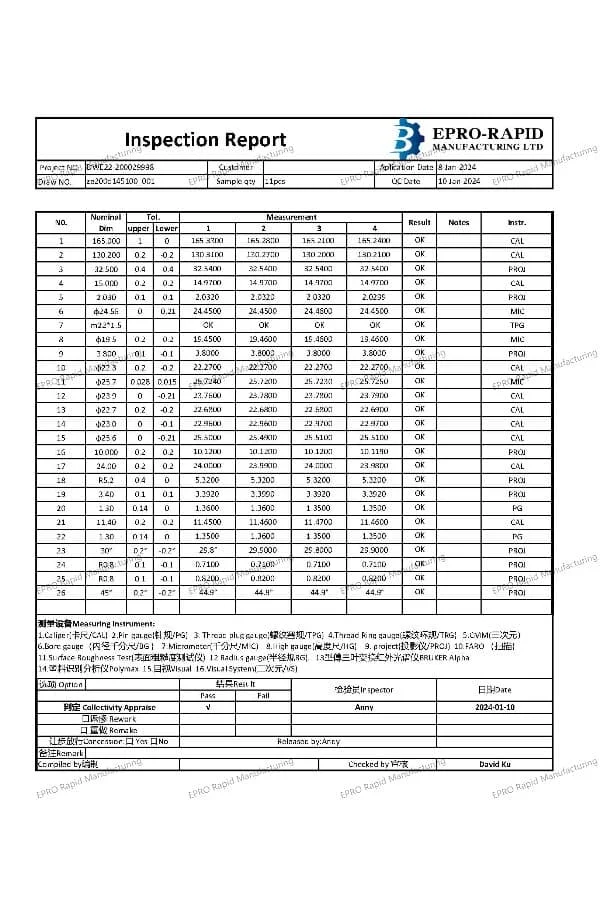

A Comprehensive Quality Documentation System

Verify quality and compliance with validation reports. Verify the accuracy and validity of the data. Check records for accuracy and completeness. Review and update documentation on a regular basis.

- ISO 9001:2015 Certificate

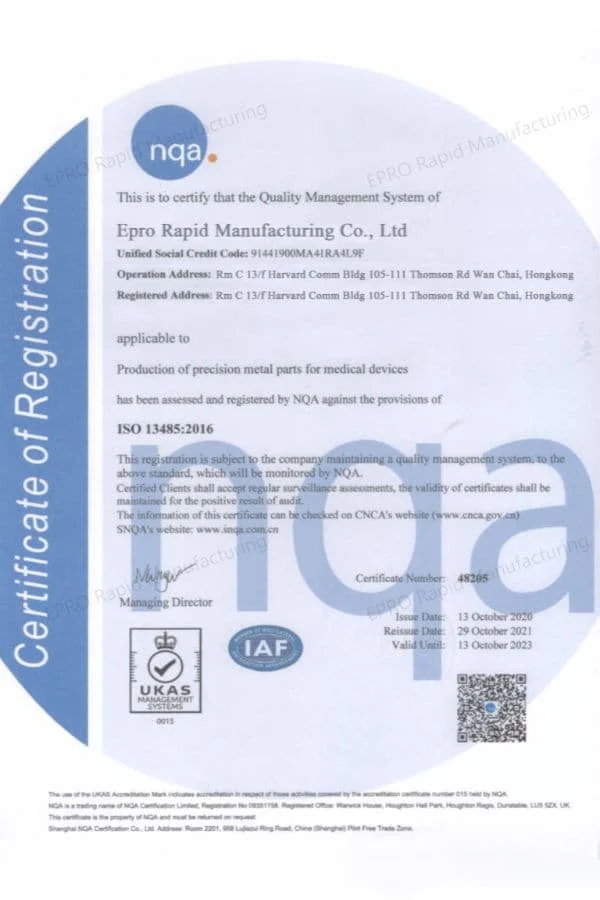

- ISO 13485:2016 Certificate

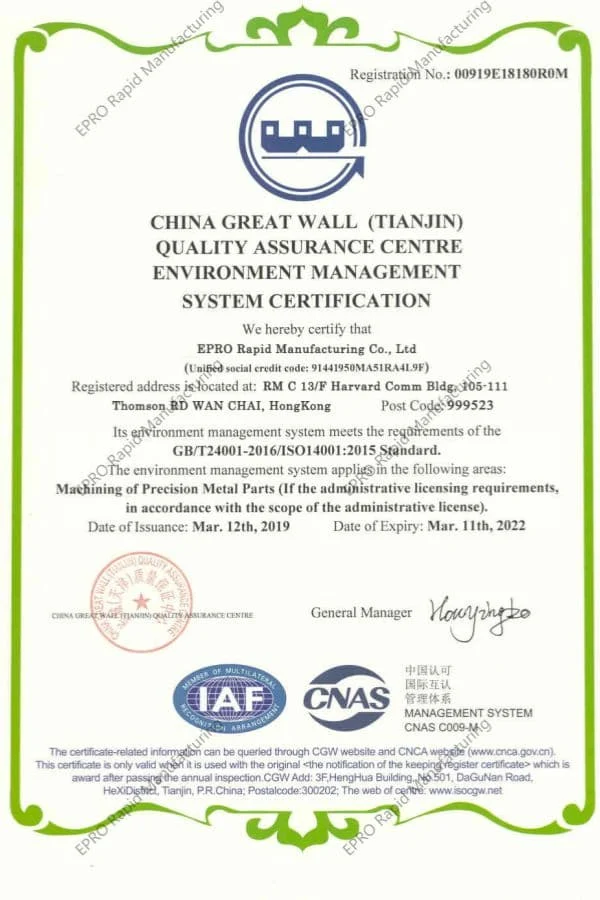

- ISO 14001:2015 Certification

- CMM Inspection Report

- Full Dimensional Inspections

- Material Test Reports

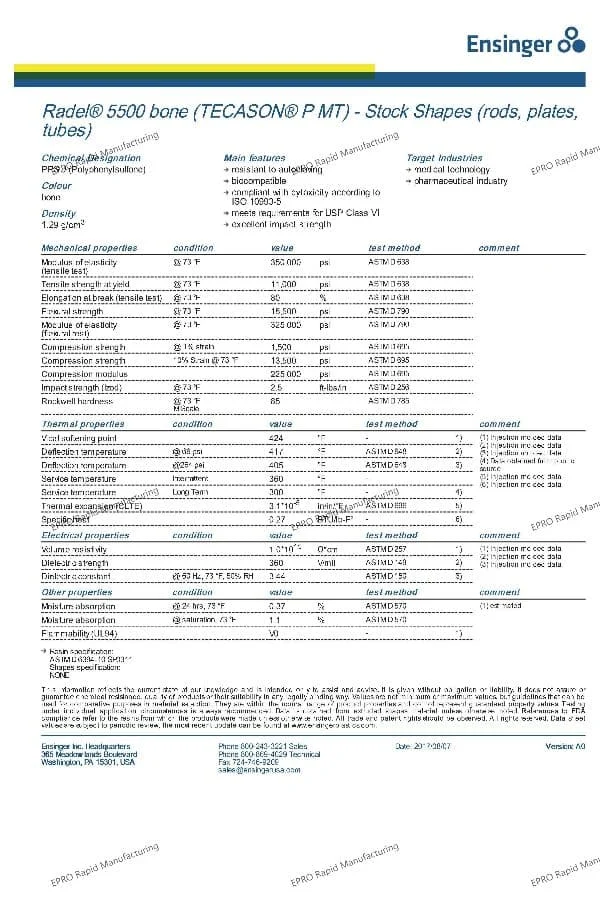

- Material Certificates

- Certificates of Conformance

- First Article Inspections

Personnel, Inspections, and Equipment

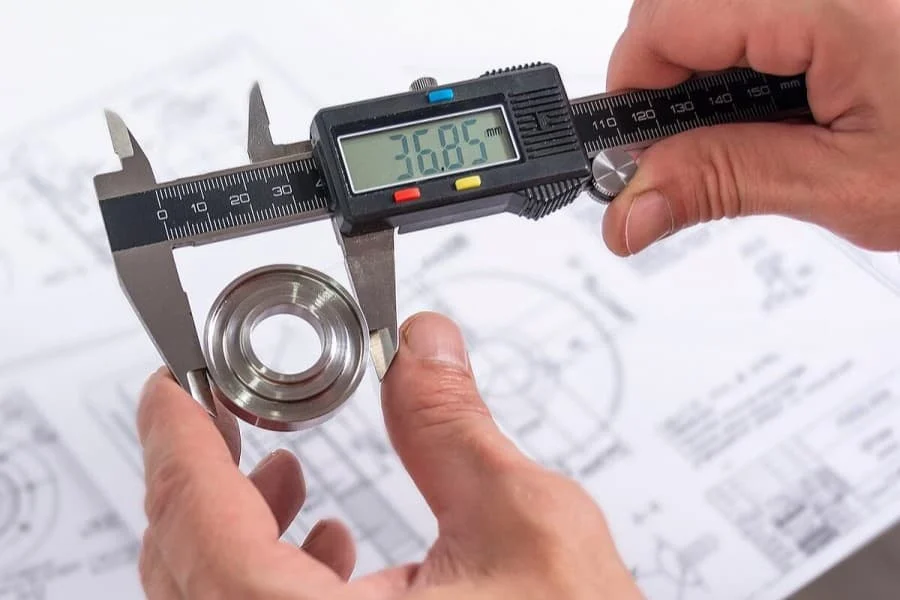

In order to produce high-quality machined parts, you need the right people on the job. We have built a team of experienced quality control experts who are continually working to verify part quality. Our people are armed with the right tools for the job and are continually conducting inspections at all stages of the production process.

Raw materials are inspected to ensure that our supply chain is performing up to standard. In-process inspections help us to catch any issues early so that they don’t develop into larger problems later. Final and outgoing inspections help us to verify that our customers only receive parts that are up to their high standards.

To ensure these inspections are effective requires that we use the right equipment. Our team uses tools such as height gauges, 2D projectors, tool microscopes, micrometers, CMM machines and more. The range of high-quality imported and domestic equipment at our disposal enables us to ensure the accuracy of your order.

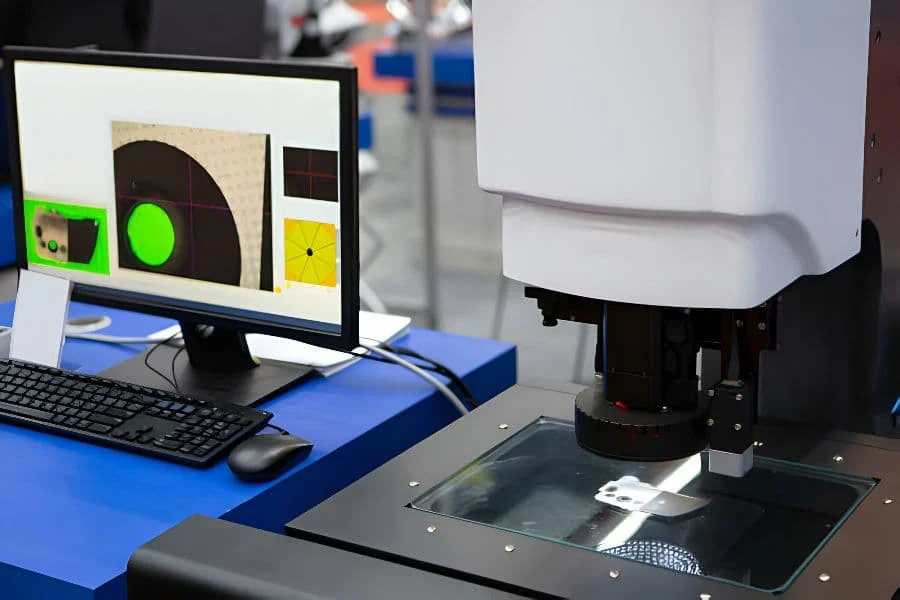

Inspection Equipment for ensure the high-quality machined parts

For these inspections to be effective, the right equipment must be used. In order to ensure machined parts meet the specifications, precision measuring tools such as calipers, micrometers, and coordinate measuring machines (CMMs) can be used. We are able to ensure accuracy of your order by using a variety of high-quality imported and domestic equipment.

Environmentally-Friendly Practices

Many companies today are concerned about the impact they are having on the environment. We have developed a system for environmental management that is continually improving and is ISO 14001:2015 certified. This system allows us to limit the impact of our operations in terms of air pollution, water and sewage issues, waste management, soil contamination, and resource usage.

Working with an environmentally responsible manufacturer enables our customers to demonstrate compliance with regulations and market demands, maintain or improve their company reputation, and achieve business aims relatating to environmental responsibility.

Let's make EPRO help you now!

You ideally want a precision machined part supplier who can meet both accuracy and precision requirements so you can make sure your parts are consistent and meet your design intent.

Need support? We're 24/7/365 at your service!

When you’re ready to start your next project, simply upload your 3D CAD design files, and our engineers will get back to you with a quote as soon as possible.