5-Axis CNC machining Service

5 Axis Machining: What Is It?

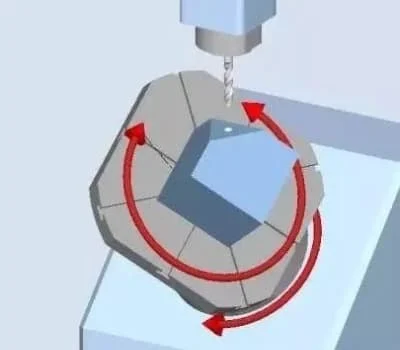

During this type of machining, tools rotate in five different directions. In this multi-axis subtractive process, workpiece material is shaped vertically or in five directions. Metals and plastics can be cut and shaped by CNC machines. This technology also produces precision components with tight tolerances.

Movement also occurs in A and B directions along with X, Y, and Z. 5-axis machining allows operators to machine parts in all directions. The workpiece does not need to be repositioned manually between operations. Also, it saves time and creates highly complex parts. Using a 5-axis machine can also reduce waste and costs. Furthermore, it is commonly used to create complex shapes with tight tolerances. Modern manufacturing relies on 5-axis machining because it is an efficient and accurate tool.

5 Axis CNC Machining Capabilities

EPRO’s advanced 5-axis CNC precision machining handles a variety of materials, producing complex parts quickly and efficiently. With state-of-the-art setups, we ensure quality CNC machining, on-time delivery, and competitive pricing.

5-axis CNC machining

EPRO-Rapid’s 5-axis CNC machining delivers unparalleled precision and efficiency for complex geometries. Our state-of-the-art machines handle intricate parts in a single setup, reducing lead times and maintaining high-quality standards. Ideal for aerospace, medical, and automotive applications.

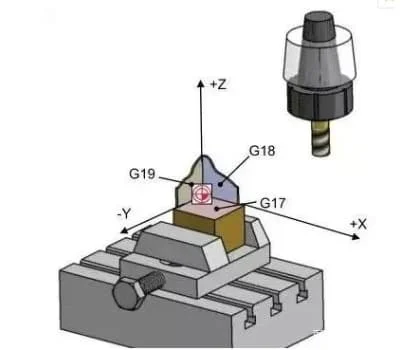

3+2 axis CNC machining

Our 3+2 axis CNC machining offers flexibility and accuracy by positioning the workpiece at fixed angles and machining across three axes. This method is perfect for parts requiring intricate detailing and multiple features, ensuring consistent quality and reduced production time.

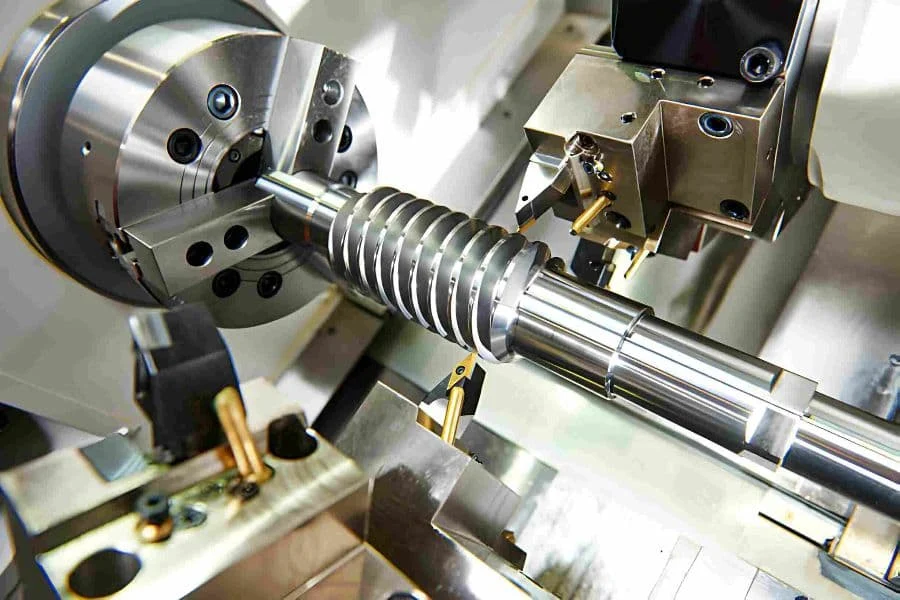

Why Choose CNC Turning?

Repeatability and Precision

The EPRO-Rapid ensures the repeatability and precision necessary to make complex, close-tolerance parts successful. This feature reduces errors and keeps the quality stringent/frame-to-frame, solving concerns of inconsistency, and guarantees performance in demanding environments.

Setting Up Effectively

5-axis machining allows us to machine complex parts in one run, eliminating the need for lengthy setup. This process is much more efficient, which not only saves time and reduces the risk of misalignment, but also solves the extended production cycle problem and helps improve production efficiency as a whole.

Quality Finish

We can produce superior surface finishes and finer details in our products to avoid sometimes unnecessary secondary operations through 5 axis machining. These are also producing high precision end products with more accurate and cost effective with addressing the issues related to the post- processing time and cost.

Rapid Production

5-axis machining with EPRO-Rapid reduces lead times and material waste, maximizing production efficiency. The technology reduces production costs with the cost per part and delivery times, providing a production chanel for high-precision components.

Get Your 5-Axis CNC Machining Quote Today

Need precision and efficiency for complex parts? Get a fast, competitive quote for our 5-axis CNC machining services. Click now to request your personalized quote!

Design Guidelines for Precision Machining

Maximum Dimensions

3-axis Milling | 36 in. x 24 in. x 13 in.

5-axis Milling | 16 in. x 16 in. x 16 in.*

Turning | 10 in. x 18 in.

*Raw block weight limit up to 75 lbs.

Maximum Dimensions

3-axis Milling | 914.4mm x 609.6mm x 330.2mm

5-axis Milling | 406.4mm x 406.4mm x 406.4mm*

Turning | 254mm x 457.2mm

*Raw block weight limit up to 75 lbs.

Minimum Dimensions

3-axis Milling | 0.10 in. x 0.20 in. x 0.20 in.

5-axis Milling | 0.10 in. x 0.20 in. x 0.20 in.*

Turning | 0.093 in. diameter

Feature | 0.0156 in.

Wall Thickness | 0.040 in.**

*Minimum material thickness for plastic and steels: 0.125 in.

** Material and geometry dependent

Maximum Dimensions

3-axis Milling | 2.54mm x 5.08mm x 5.08mm*

5-axis Milling | 2.54mm x 5.08mm x 5mm*

Turning | 0.093 in. diameter

Feature | .396mm

Wall Thickness | 1.016mm**

*Minimum material thickness for plastic and steels: 3.175mm

** Material and geometry dependent

5-Axis CNC Machining Materials

High precision 5-axis CNC machining for a broad range of materials, including aluminum, copper, stainless steel, titanium, and plastics. Perfect for small parts with intricate designs and advanced geometries, we deliver superior performance to suit various project requirements.

Aluminum

With the right lightness concentricity and zu sehr affordable price point, Aluminium is suitable for aconitum blank machining. Thanks To Its High Strength-to-Weight Ratio, Corrosion Resistance, Aerospace, Automotive, And Consumer Electronics Uses.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Aluminum

Copper has amazing electrical & thermal conductance and is highly coveted. It is suitable for parts in electrical applications that require tight tolerances and effective heat dissipation; these applications may include heat sinks and electrical connectors.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Brass

Known for its machinability and corrosion resistance, brass is perfect for applications such as plumbing, electrical applications, among general applications, and even decor.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is extremely durable and naturally resistant to corrosion. Well suited for medical, automotive and food processing equipment where sterilization and durability are paramount.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Titanium

Titanium is used in many different types of applications, and helps to offer high strength, low weight, and is also incredibly corrosion resistant. Used in aerospace, medical implants, and high-performance auto parts involving where strength and biocompatibility is very important in these parts.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Plastics

Such as ABS, POM and Nylon.With plastics, you can get closest because CNC machining of plastics provide excellent versatility for producing lightweight, durable components. They are versatile and cost-effective, which makes them a popular choice in consumer electronics, automotive interiors, and medical devices.

| POM | PEEK | HDPE | PET |

| Nylon | PTFE | PVC | PP |

| ABS | PC | PMMA |

5-Axis CNC Machining for Various Industrial Applications

EPRO-Rapid’s 5-axis CNC machining excels in producing complex parts for aerospace, automotive, medical, and consumer electronics industries. By offering unmatched precision and efficiency, we address industry pain points such as tight tolerances, intricate geometries, and rapid turnaround times, ensuring seamless production and high-quality results for diverse industrial needs.

Aerospace & Defense

EPRO-Rapid provides CNC milling service with 5 axis to ensure even the most difficult to reach machined areas with great precision, which is ideal for aerospace and defense solutions that require high levels of accuracy & complex geometry for extreme reliability and performance.

Automotive

CNC precision machining parts for cars, EPRO-Rapid has excellent automotive precision machining technology, can produce automotive parts, can solve the design difficulty problem, to produce high quality automotive parts, so that cars more durable, reliable, more powerful.

Medical

EPRO-Rapid of cnc metal machining, to create precise manufactured medical apparatus and instruments, biocompatibility and a number of production process standards for you to meet the requirements of a higher level of medical staff.Let’s try EPRO-Rapid Today!

Robotics and Automation

Our precision cnc machining manufacturers offer parts for robotics & automation that will address the challenge posed by accuracy and repeatability, ensuring smooth integration and the best possible functionality.Let’s try EPRO-Rapid Today!

Consumer Products

We combat mass production and highly multiplex products design using our 5 axis cnc machining services delivering high-quality, complex components that guarantee both aesthetic and functional properties.

More Industries

Design services

New energy

Electronics & Semiconductor

Education

Industrial Machinery & Equipment

Supply Chain and Purchasing

Put your parts into production today

All information and uploads are secure and confidential.

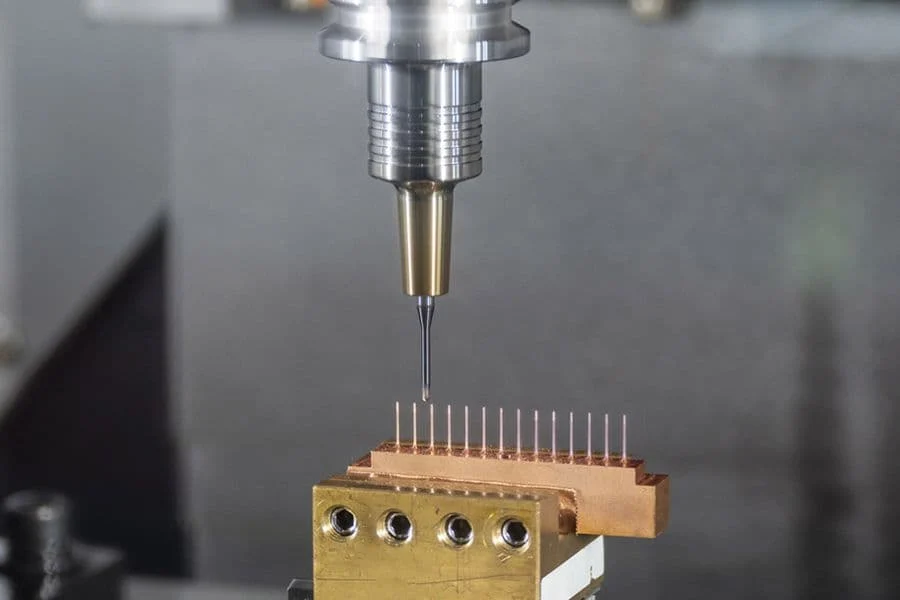

Tour Our 5 Axis Machine Shop

Check out the superior horizontal and vertical machines of the EPRO-Rapid range of 5-axis machining centers. The highest level of service and efficiency is guaranteed for all types of businesses with our state-of-the-art equipment and experienced technicians. Improve your components with our high-quality 5-axis milling services. Get in touch with us now and set up your date to visit to know more!

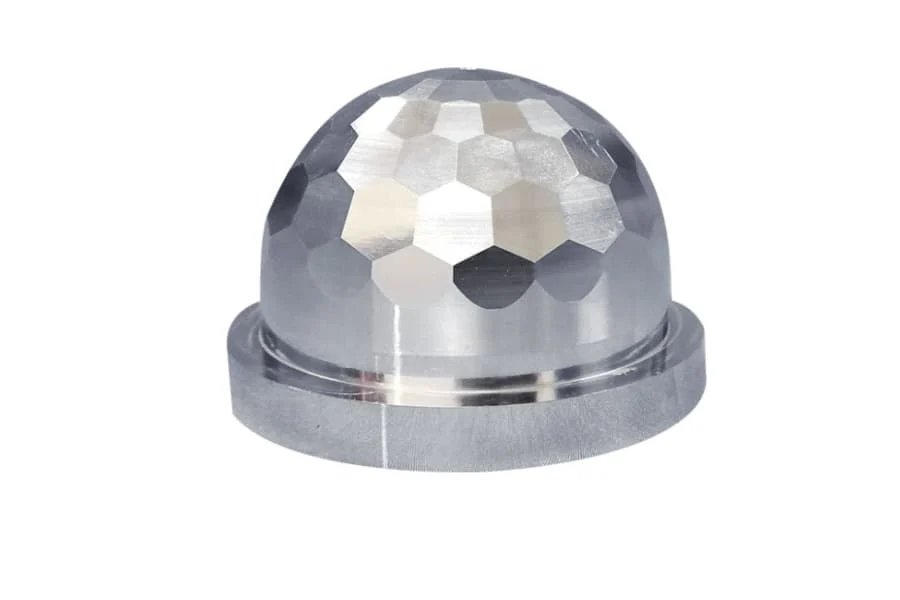

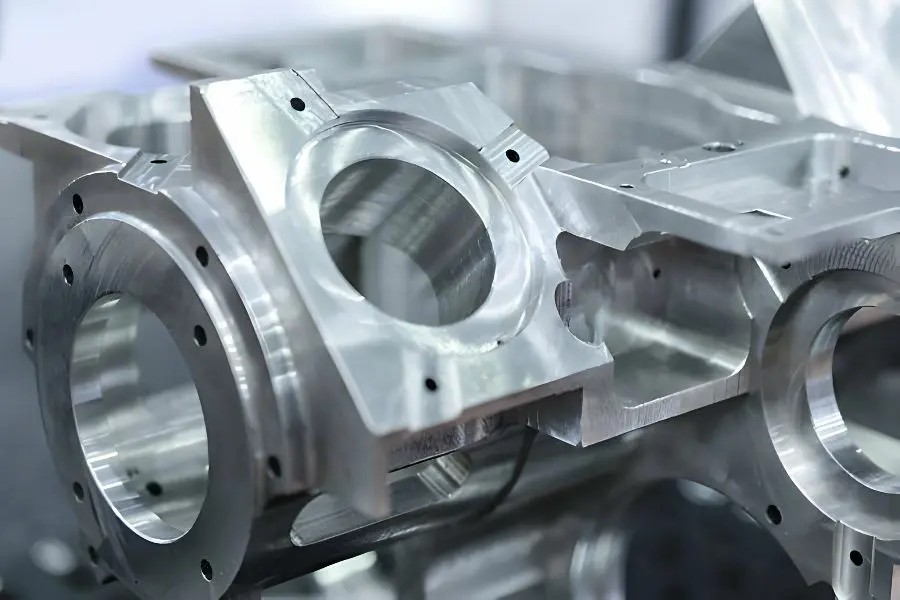

Gallery Of 5-axis CNC Machining Parts

Discover our 5-axis CNC machining parts for aerospace, automotive, medical, robotics, and consumer products. We utilize diverse materials like aluminum, titanium, and stainless steel, with finishes such as anodizing and polishing, ensuring top quality and precision.